LBR II mechanics

The design of the mechanical parts and the integration of all electronic components was done by using modern software technics such as virtual prototyping.

The geometries of all parts were shaped using the fully parametric 3D-CAD-System ProEngineer. These geometries were given via standardinterfaces to other programs for simulating stresses, displacements (both by using finite element methods, FEM) and kinematics (by using a multibody simulation). ProEngineer offers the possibility to run FEM (Mechanica) and a multibody simulation (ProSim, SIMPACK) in the same environment as ProEngineer. This was done excessively.

Other interfaces of our CAD system made it possible to exchange the outlines of electronic boards and the geometry of electronic parts including these part´s placement on the board. Therfore all electronic components could be shaped in CAD and effectively integrated in the whole design.

This way we build up a knowledge base which contains all important information for the manipulator´s construction. It enables us to create a highly integrated mechatronic system, which is very lightweight and meets at the same time the demands of modern control technics.

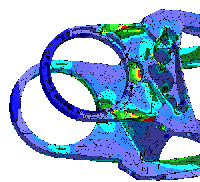

The use of extremely light-weight structures requires to take a close look at the highly charged mechanical parts. It is necessary to optimize stiffness and strength of the structures while keeping in mind that weight must be reduced and everything has to be as easy to manifacture as possible.

The main structure is non-modular. This way, the costs for manifacuring increase but it is the only way to maximize the payload to weight ratio.

Using expendable FEM calculations, stresses and displacements of all critical part were determined.

If you can achieve, that stresses don´t change much in your structure, you have used the material best you can..

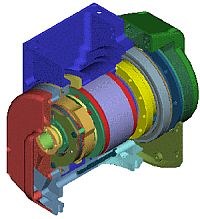

Each component was ordered from an industial manufacturer and optimized to be more powerful and lightweight.

The electromagnetic safety brake of Fa. Mayr was redesigned and loosed 60% of its former weight. This was possible because we designed a new control electronic which reduces power consumption and power loss and therfore enables an optimized thermal design.

We equipped brushless DC-motors of Kollmorgen with analog hall effect sensors instead of the digital ones. Therefore the measuring of the motor position could be significantly enhanced as well as the quality of control. We use the motor position signal to commutate the motor and for joint control.

The gears of Harmonic Drive provide a high reduction ratio (1:160) and no backlash at very high efficiency. First we save material by doing a clever connection. Then by using new designed gears with a lot of aluminium components the over-all weight could be reduced again.