Software development

For software development, modern tools such as the DLR GitLab instance for contemporary collaborative software development are used to implement DLR's software engineering guidelines and ultimately to ensure the quality and functionality as well as the maintainability and expandability of our research software.

Our software tools are used in national and international research projects and are also used for direct contracts - such as the DLR Simfuel® platform for prescreening new fuel candidates or SAF prior to certification in aviation.

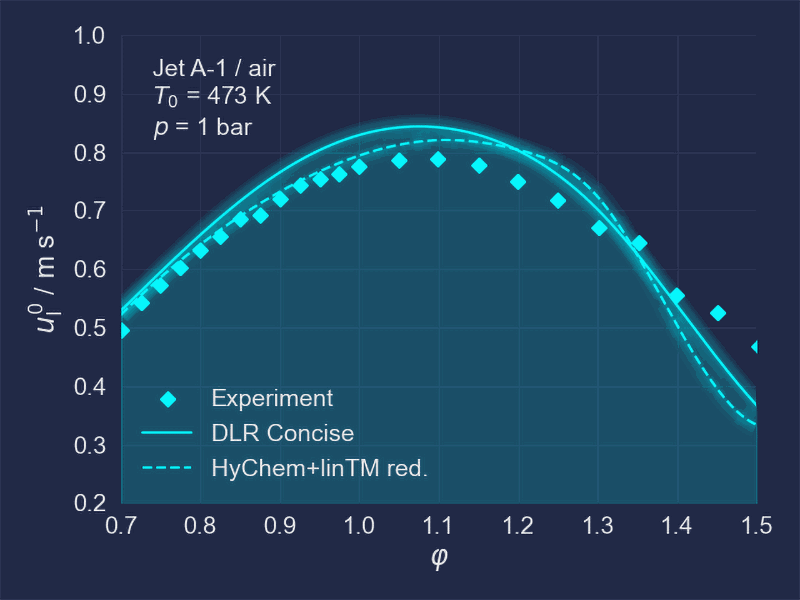

The basis of any theoretical analysis of combustion processes are chemical reaction mechanisms, which are often very extensive. For use in numerical fluid mechanics or theoretical considerations and model developments, it is often necessary to reduce the original mechanisms to significantly smaller, reduced mechanisms optimised for an "operating range". Here, the linTM programme offers an excellent tool for the efficient reduction of chemical reaction mechanisms.

Micro gas turbine based and novel cycle processes are investigated and optimised with the MGTS3 process simulator. Any system components can be interconnected and their stationary and dynamic behaviour investigated.

The ProCoSim programme enables the process simulation of system networks consisting of producers, storage facilities and consumers. For example, the operating strategy of combined heat and power plants for supplying office buildings can be optimized and integrated heat storage systems can be dimensioned to meet the demand profiles over the course of the year.

In order to evaluate and optimise existing and future sustainable fuels - especially sustainable aviation fuels (SAF) - an interactive, interdisciplinary and collaborative digital platform for the evaluation and optimisation of fuels was created with the DLR SimFuel® platform, which is continuously being further developed by the team. In addition to state-of-the-art models of fuel properties, a comprehensive database has also been set up, which currently contains 15,000 conventional jet fuels and 450 new types of fuel. In particular, the platform also offers an interface and interactive web dashboards that enable external project participants and customers to make optimal use for collaborative research.

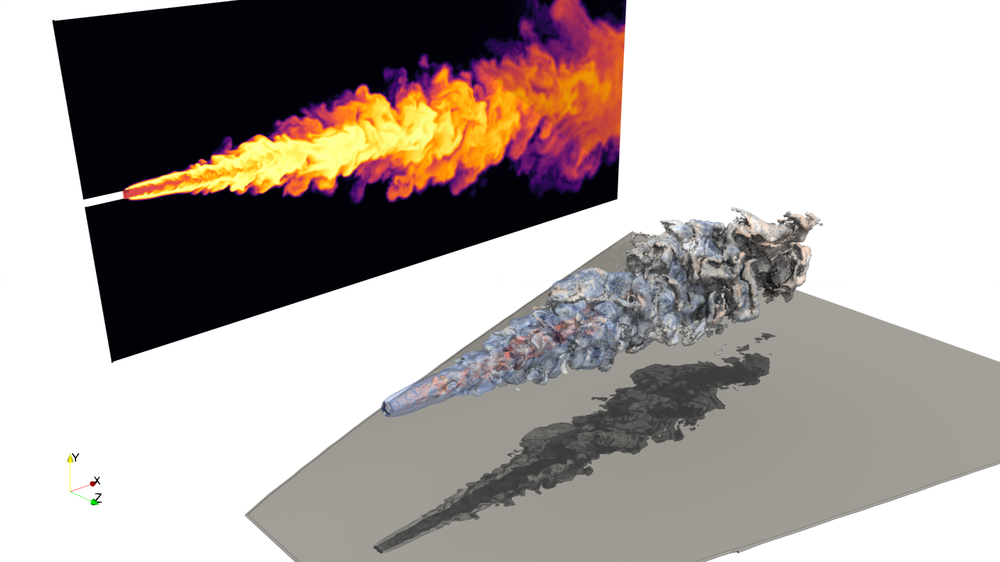

For the efficient calculation of turbulent, chemically reacting flows in complex three-dimensional geometries, the institute's own combustion code ThetaCOM is being continuously developed and applied. This allows both complex detailed problems to be analysed and application calculations to be carried out as part of design processes.