Chemical-kinetic reaction models

Chemical-kinetic modelling is the key to understanding and simulating reactive combustion processes. Our aim is to develop, optimise and provide accurate and efficient models for CFD that are directly applicable for initial fuel evaluations and combustion system predictions.

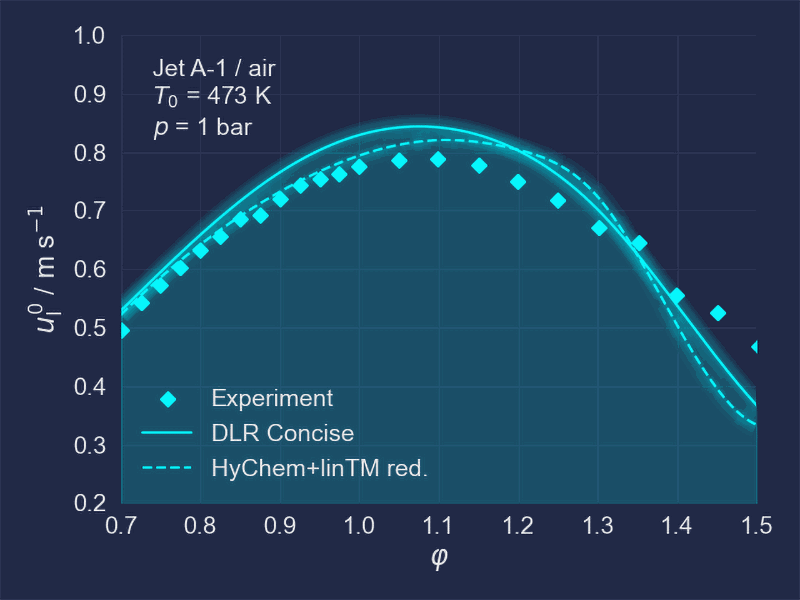

The department's core competences include the creation and further development of detailed chemical-kinetic models for fuels used in aviation, space, transport and energy conversion. Model development is complemented by the creation of efficient, fuel-specific Hybrid Chemistry (HyChem) models. The competences are supported by quantum-chemical methods for the determination of thermo-physical properties and decisive reaction rates as well as by in-house experimental investigations in shock wave tubes, flow reactors and laminar burners.

Advanced optimisation methods are developed and used to increase the accuracy of chemical-kinetic models. The department uses the in-house, highly efficient method of linear transformation modelling (linTM), which reduces numerical costs by orders of magnitude compared to conventional methods. This opens up new possibilities for optimising extensive chemical-kinetic models with comprehensive experimental data at a numerically justifiable cost.

The method of rapid reduction of chemical-kinetic models is derived on the basis of analysis and optimisation methods of linTM. The resulting reduced models enable significantly higher degrees of reduction compared to conventional methods. By re-optimising the reduced model for intermediate species, ignition delay times and flame velocities, a high degree of accuracy is achieved at the same time - similar to a detailed model.