Decentralised electricity and heat supply

By the end of the decade, the share of renewable energies will rise to at least 27 per cent, and a similar improvement will be achieved in energy efficiency. At the same time, greenhouse gas emissions will be reduced by at least 40 per cent compared to 1990 levels. An energy system powered by renewable energies needs stabilising technology. Decentralisation is the answer. The closer the energy is produced to the consumer, the fewer transmission losses there are. Decentralised energy systems also offer the opportunity to establish a low-threshold hydrogen economy.

What are decentralised power plant concepts?

Decentralised energy systems (DES) are defined by the fact that energy is generated in the immediate vicinity of the end consumer. Such grids rely on a large number of smaller power generation plants and storage units that are connected to the grid to supply energy. Decentralised energy systems are either self-contained, as in remote regions, or small systems that interact with other neighbouring systems. A decentralised energy network is far more resilient in the event of a disaster than a centralised energy supply network. If one part fails, other grids can step in. Decentralised energy systems range in size from a few kW at building level to several dozen MW in the case of urban districts or smaller communities.

What could decentralised energy systems look like in the future?

Industrial companies and residential neighbourhoods must be organised in the form of a separate local grid. The residential district would have a decentralised system with many independent consumers and producers. The energy system can utilise various renewable sources such as wind, photovoltaics and geothermal energy. These sources can be combined with heat and battery storage or hydrogen production using electrolysers. Decentralised energy systems are a very good way to enter a hydrogen economy.

Decentralised energy systems that produce their own hydrogen on site will supply rural communities, remote locations and industry with reliable, carbon-free energy. In Power to Hydrogen to Power applications, renewable energy technologies supply electricity to the grid. Any surplus energy is stored in hydrogen and used when needed. This can include both short-term and seasonal storage.

The levelised cost of hydrogen (LCOH) depends mainly on the cost of renewables and the electrolyser. Given the current capital costs for PV, wind, electrolysers and storage, the LCOH calculator of the European Turbine Network (ETN) calculates an LCOH of around €7-10/kg for decentralised applications.

How are microturbines integrated into such systems?

Gas turbines are well-suited to integrating fluctuating renewable energy sources into complex energy systems, thanks to their high load flexibility, partial load efficiency and fast start-up and shut-down times. At the present time, the combination of renewable energy sources with a gas turbine as a balancing component for the fluctuation of renewables and in combination with hydrogen or biogas as long-term energy storage is still somewhat uncommon. Typically, the electricity grid serves as a backup. However, as the proportion of renewable electricity increases, such combinations may become increasingly relevant in view of the volatile electricity supply.

For such application scenarios, however, the gas turbine technology must be optimised for economic reasons. In addition, the adaptation to certain fuels or the combination of different fuels is advantageous in order to increase independence. However, today's gas turbine technology can already fulfil such applications.

What are our current research topics?

One of the key factors for the competitiveness of microturbines is high efficiency. While the overall efficiency of the systems is high, as the waste heat can typically be utilised in decentralised applications, there is room for improvement in the electrical efficiency, which is somewhat lower than competing technologies. We are exploring ways to increase both the electrical and overall efficiency of microturbines. This is possible both by improving the components and optimising the cycle processes.

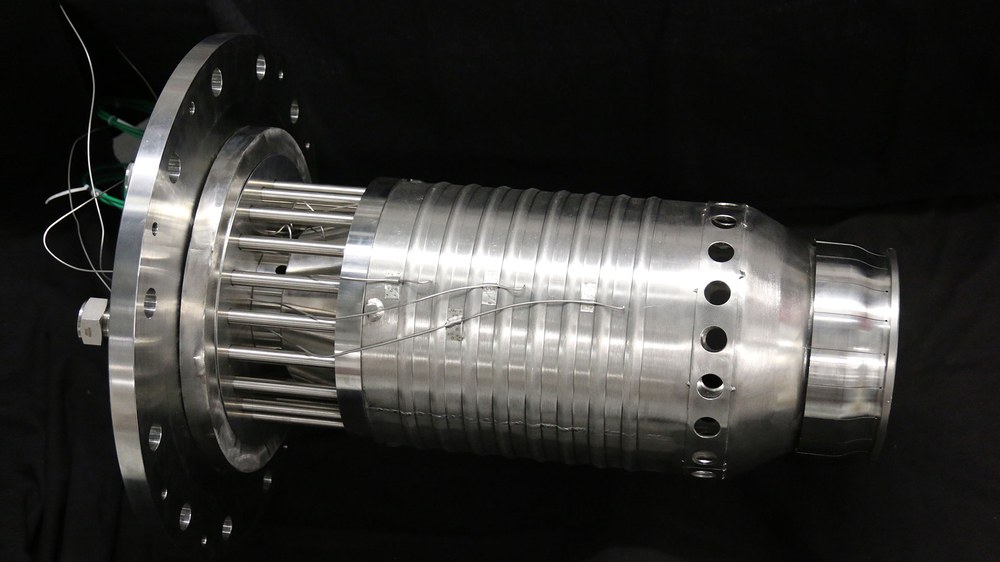

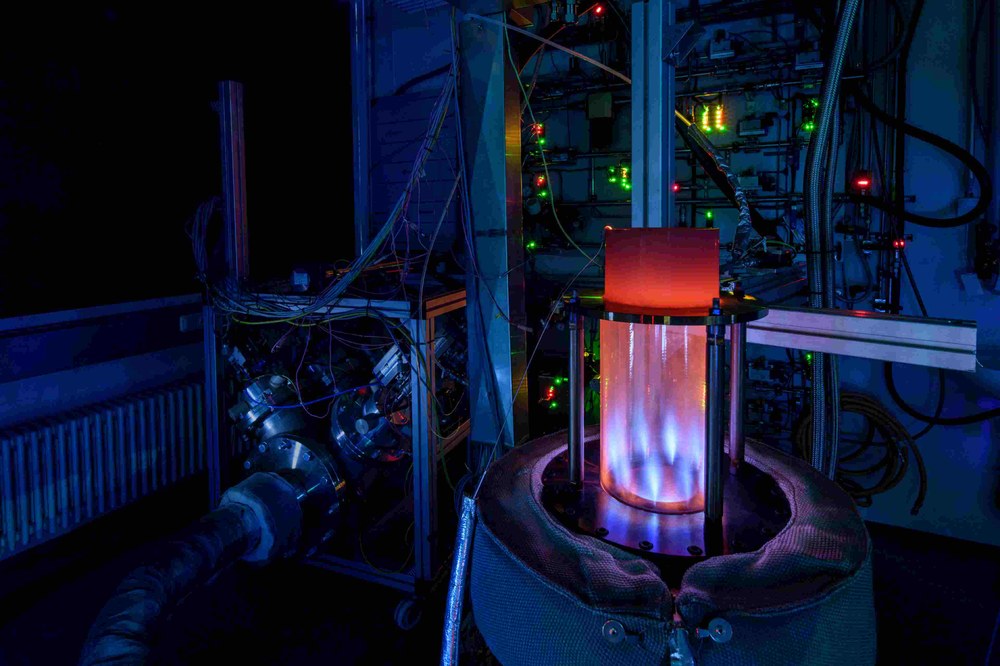

We are also exploring ways to stabilise the flame, with a particular focus on the combustion of hydrogen. It is our considered opinion that flame stabilisation is of fundamental importance for the efficient performance and reliable operation of the gas turbine. We are therefore focusing our research and development efforts on jet-stabilised burner systems. In these burners, we have found that stabilisation can be achieved by jets, i.e. axial jets with a high momentum, which are introduced into the combustion chamber through openings.

This axial jet stream is designed to ensure strong recirculation in the combustion chamber and lead to intensive mixing of the burnt gas with the fresh fuel-air mixture. To create an internal recirculation area, the openings are arranged in a circle. The absence of low velocity zones results in high flashback resistance, which is why this concept is recommended for applications with multiple fuels or very high combustion chamber inlet temperatures.

In decentralised applications, we believe that the reliability of the technology and the ability to plan maintenance are also essential in order to minimise unplanned outages. In order to improve the reliability of microturbines, we analyse typical cases of damage and further develop the individual components together with manufacturers. We are working on monitoring concepts and the early detection of maintenance requirements in order to increase the reliability of microturbine systems.