Development of new combustion chambers

Even under the changed framework conditions of the energy transition, combustion remains an important pillar of global and national energy generation.

The conversion of stationary gas turbines and aircraft engines to operation with non-fossil fuels such as hydrogen or fuels from power-to-liquid processes is an important component of the energy transition and the subject of our current research.

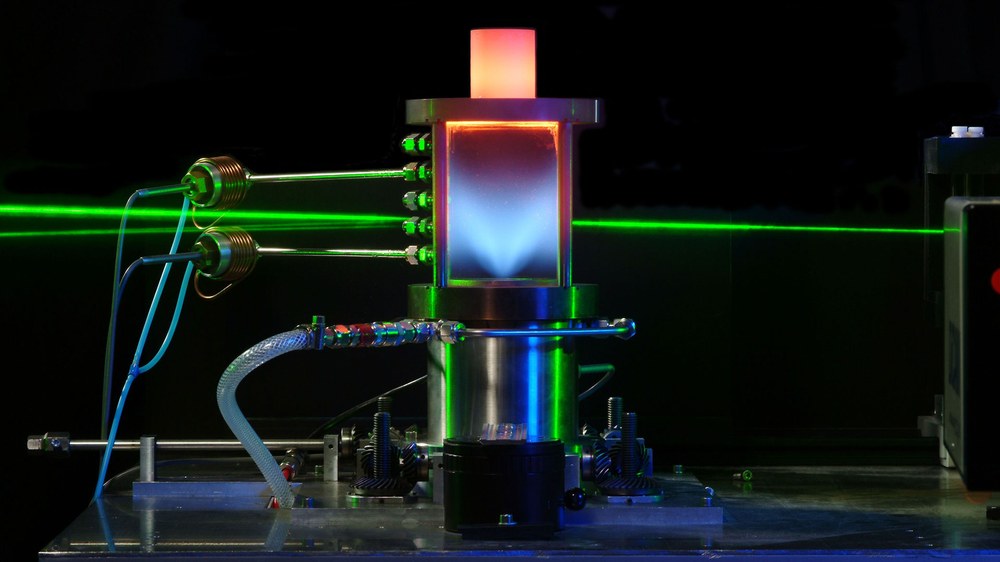

To this end, we are pursuing a multi-track approach: we are developing optical, laser-based and conventional measurement methods on sprays, atmospheric burners and high-pressure combustion test benches and thereby generate validation data sets for combustion simulation under defined conditions. Subsequently, we use the understanding of combustion in gas turbine combustors and the complex sub-processes involved in this process in a second step to continuously improve combustion systems of stationary gas turbines and aircraft engines.

In our projects, we are working on combustion systems of the next and next but one generation in the range of a few kW to MW, whose pollutant emissions are further minimised with high load and fuel flexibility. We transfer results from laboratory experiments to the high-pressure environment, and we address questions from industrial combustion in simplified experiments at atmospheric pressure in order to find solutions using optical diagnostics.

The focus of our research is the optimization of jet-stabilised combustion with recirculation, also known as FLOX® gas turbine burners. We are developing this concept for liquid and gaseous fuels in an application-oriented manner. Our combustor concept, which is based on the FLOX® gas turbine burner, has proven to be a promising approach, especially for the combustion of hydrogen

The department operates a number of atmospheric and high-pressure combustion test stands with optically accessible combustors between few kW and beyond 1 MW power, in which we investigate details of technical combustion processes with modern optical and laser-based measurement methods. These techniques are non-intrusive, with high spatial and temporal resolution and can determine two-dimensional distributions when employing light sheets.

Therefore, an important focus is the optimization and adaptation of modern laser-based techniques for combustion as well as spray diagnostics. We also use customised diagnostics to support project partners and customers from industry by characterizing the combustion behaviour of industrial burners and thus optimizing the systems individually.

We develop, optimized and adapt following optical and laser-based diagnostics with 10 Hz and - where possible - kHz repetition rate systems: