A small taste of the future

This article in the DLR magazine describes how our DLR Prescreening® is accelerating the approval process of sustainable aviation fuels.

The introduction of alternative fuels for civil aviation is associated with major challenges for manufacturers, even though the demand for sustainable aviation fuels (SAF) is now increasing - not least due to the new legal requirements for blending quotas in the EU and the USA. With prescreening, we offer an opportunity to test and characterise the properties even before approval and with small quantities.

The approval for new types of fuel is extremely complex because safety is a top priority in aviation. This prioritisation is unavoidable, but also represents an enormous hurdle for innovations. This is because fuel manufacturers lack important information about the suitability of their fuel for approval in the early stages of development, when sufficient quantities are not yet available for experimental tests. Against this background, the researchers at the institute have developed a method based on probabilistic machine learning algorithms to evaluate new fuel candidates with regard to the requirements for approval: the DLR Prescreening®. We make the resulting information available to fuel-producing partners to enable holistic product development and reduce the risk of subsequent approval. With the Technical Fuel Assessment, we offer a further, scientifically in-depth and comprehensive service aimed at the targeted optimisation of a fuel for the respective purpose.

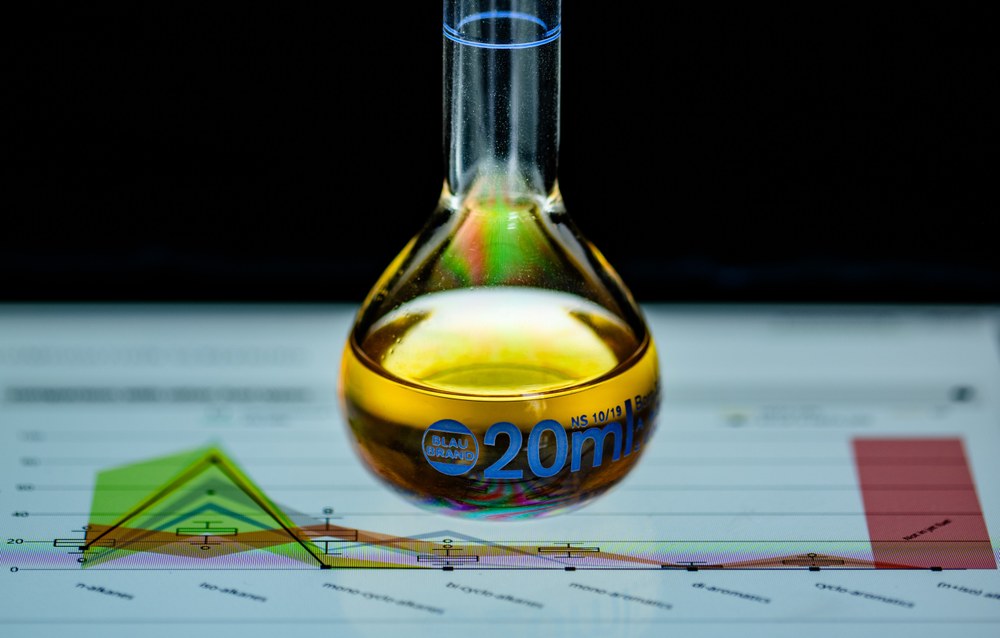

Our prescreening process is based on the two-stage procedure developed in collaboration with the National Jet Fuels Combustion Programme (NJFCP). The analysis is possible with just a few millilitres. First, the fuel composition is analysed in the laboratory using qualitative and quantitative two-dimensional-gas chromatography (GCxGC) and trace component analysis. The composition is analysed component by component according to C-number and substance group. Then, in a second step, selected properties of the fuel candidate are predicted using the property models of the DLR Simfuel® platform and compared with other fuels and specification limits. The database, which was also set up as part of the Jetscreen project, now contains data on more than 15,000 conventional jet fuels and more than 450 new types of fuel, as well as numerous analyses of the most important molecular groups and models for material properties. Many of these fuels originate from research projects that have made their data available.

Our team uses supervised machine learning to predict the properties for the comparative analysis. The algorithms are trained with the data from the DLR Simfuel® platform. They are then used to simulate and evaluate the properties of a new candidate based on the detailed gas chromatography results. The visualisation of the results in specially developed, complex diagrams makes it possible to see at a glance what behaviour a fuel will exhibit later - and, above all, whether these properties are within or outside the specifications set by the ASTM.