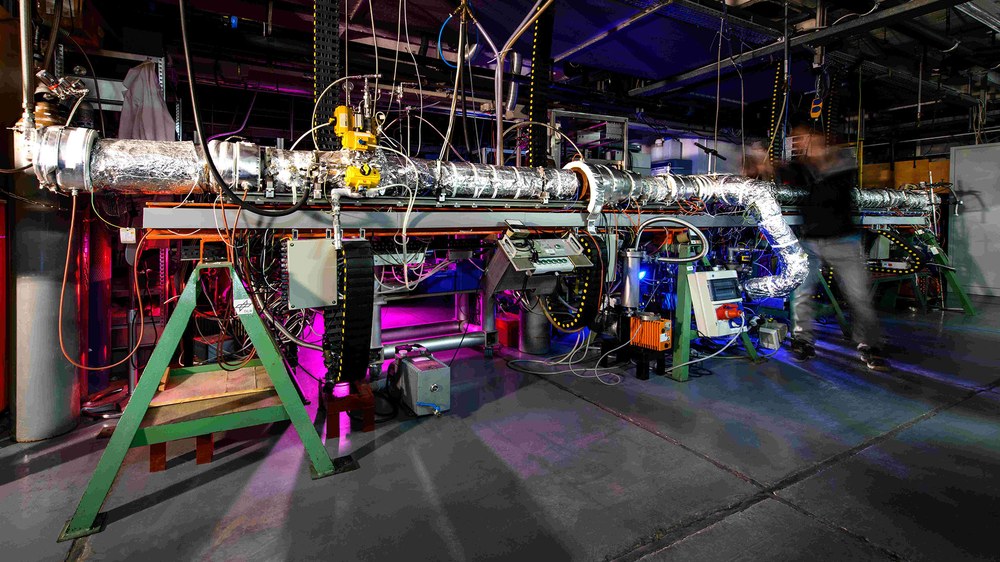

Shock tube laboratory

The shock tube facility at the DLR Institute of Combustion Technology in Stuttgart can be used to heat and compress ignitable gaseous mixtures to combustion-relevant temperatures and pressures in microseconds. The large-scale research facility at the German Aerospace Center (DLR) is used to develop and validate chemical-kinetic reaction mechanisms, which are used to simulate combustion processes in gas turbines, furnaces and rocket combustion chambers, among other things.

Three shock wave tubes and the associated diagnostic and chemical-analytical infrastructure are combined in the large-scale research facility. The individual shock tubes are dedicated to different tasks and equipped according to the area of application. With the provision of ignitable mixtures by the facility, the boundary conditions under which, for example, fuel and propellant mixtures ignite and the time from which these conditions prevail are defined in the best possible way and can be kept constant over a period of a few milliseconds until the mixture ignites spontaneously. In addition, product distributions of stable species can be measured and the development of individual reactions over time can be tracked by measuring the absorption of specific radicals.

Extreme mixing ratios and their combustion properties

The ignition delay times determined in the shock tube facility characterise the chemical-kinetic reaction system as a function of temperature, pressure and the ratio of fuel to oxidiser. Extreme mixing ratios and conditions can also be tested here, which are not achieved in a technical combustion system in normal operation, but are relevant to the design. Product distributions, on the other hand, represent a state of the reaction system that has been virtually "frozen" after a defined time.

The shock tube facility represents a part of the kinetic experimental portfolio (see also Reaction kinetics experiments) required for the development and validation of chemical-kinetic reaction mechanisms (combustion models), which are used for the simulation of combustion processes in gas turbines, furnaces, rocket combustion chambers and many more (please refer to Chemical-kinetic reaction models). In these CFD (Computational Fluid Dynamics) simulations, aspects such as fuel flexibility, low-pollutant combustion, extinguishing limits and thermal acoustics are important design parameters, for the simulation of which a combustion model adapted to the respective conditions must be derived. In addition, real and complex fuels and their mixtures can be directly compared with each other in terms of their characteristic combustion properties in order to draw conclusions about their combustion behaviour in an existing process.