Technical Fuel Assessment

The Technical Fuel Assessment is a comprehensive, bespoke analysis that - unlike the prescreening of new sustainable fuels in aviation - is in principle applicable to any chemical energy source from the aerospace, marine or ground-based transport sectors.

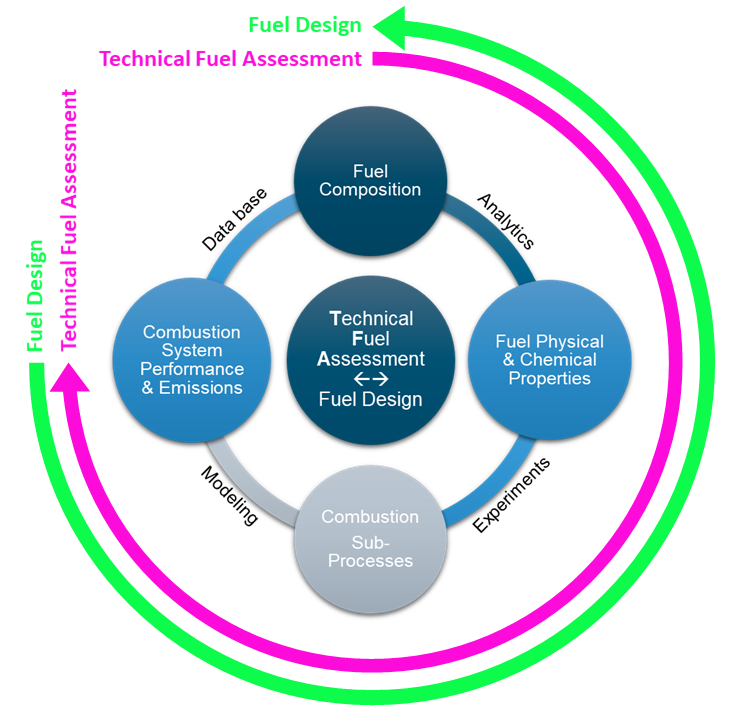

Liquid fuels are thoroughly tested for their use in various propulsion systems - be they gas turbines, piston engines or rocket combustors. This process is known as technical fuel assessment. For us, this is a multi-stage process that gradually increases in complexity.

A customized process

The Institute of Combustion Technology carries out these assessments primarily for sustainably produced synthetic fuels. The departments involved have developed a concept that allows for an individual combination of numerical investigations and test bench experiments for each fuel candidate. This combination is selected on the basis of the fuel type and the proposed application to ensure that each assessment is precisely tailored to the fuel being evaluated.

In principle, it is possible to carry out an evaluation with fuel quantities of only a few millilitres, provided that the focus is on the certification of the fuel. In this case, the basic properties of the fuel are first tested to ensure that it meets the necessary criteria for further testing and subsequent use - this assessment is also known as DLR Prescreening®.

Evaluating the fuel performance in technical systems

DLR

Conversely, when there is more fuel available, the assessment goes a step further to evaluate the fuel's performance in technical systems. This may involve testing the fuel in experiments for fuel injection, for chemical conversion, in high pressure test rigs like HIPOT and HBKS or in real-life applications on planes, vehicles and ships.

In scientific projects for fuel optimization, this process of technical fuel assessment is not a one-time affair. It's repetitive and iterative, allowing for the optimization of the fuel's technical performance and an evaluation of its environmental and climate impact. Through this continuous testing, fuels can be designed and modified to meet specific optimization targets. This process also enables researchers to analyse and minimise the impact on people, the environment and the climate.

New fuels require a new methodology

However, there is a significant challenge. The methods and approaches used to date for fuel assessment are based predominantly on investigations into fossil fuels. These methods are of little or no use when it comes to assessing novel fuels from renewable sources, which behave differently and have different properties. Therefore, there is an essential need for new methodologies and models to assess these modern, alternative fuels. The development and expansion of these methods is a primary aim of ongoing research and development work in this field.

In conclusion, the technical fuel assessment is an essential process that enables us to use fuels safely and efficiently. As we move towards sustainable fuel sources, our research will continue to evolve and adapt this process.