ThetaCOM – numerical flow and combustion simulation

ThetaCOM (Turbulent Heat Release Extension of the TAU-Code for COMbustion) is the institute's own programme for numerical flow and combustion simulation. It is mainly used for the calculation of reactive flows in combustion chambers of gas turbines.

A variety of approaches and models can be selected:

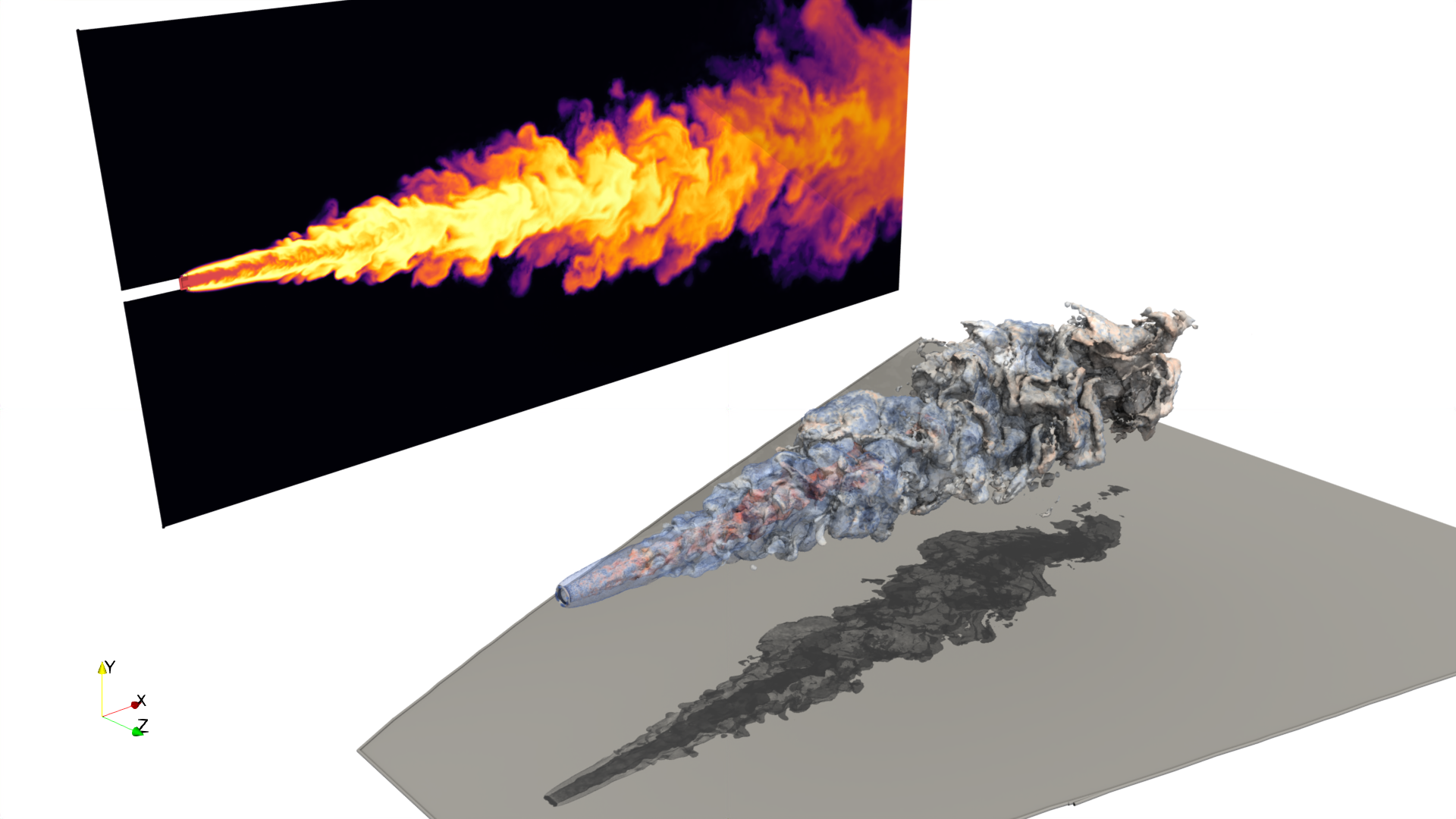

- For turbulence modelling, several two-equation models are available to close the steady RANS or URANS ("Unsteady Reynolds-Averaged Navier Stokes") equations. However, it is also possible to capture the turbulence with scale resolution and time accuracy, so that only the fine structures need to be modelled ("LES - Large Eddy Simulation").

- The interaction of combustion and turbulence is covered by a wide range of combustion models. These range from very simple, economical approaches to very time-consuming transport equation PDF methods.

- Furthermore, almost all pollutants produced during combustion can be calculated with ThetaCOM. Complex soot models can be used to calculate not only the soot volume fraction but also the soot size distribution.

- To capture liquid fuels, a separate Lagrangian spray module (SPRAYSIM) is coupled to ThetaCOM, with which fuel droplets are tracked through the computational domain until complete vaporisation.

- ThetaCOM can be used for incompressible or weakly compressible flows. The latter enables the simulation of thermoacoustic problems in combustion chambers.

- Many problems require the highest possible spatial resolution of all flow structures. In ThetaCOM, clean higher order (third order) discretisations can be achieved even on highly distorted grids.

Such simulations should also be possible for complex geometries. ThetaCOM is therefore based on unstructured computational grids. Numerous different numerical methods are also available for solving the systems of equations. Combustion simulations are usually carried out in parallel, often on many thousands of computing cores. ThetaCOM also shows very good scaling on large, high-performance computing systems and is therefore a modern, advanced and highly efficient tool for designing combustion chambers.