AddComps - Additive Composite Structures® strategy field

The aim of this strategic field is to increase production efficiency by combining conventional fibre composite manufacturing processes with additive manufacturing - in particular additive extrusion.

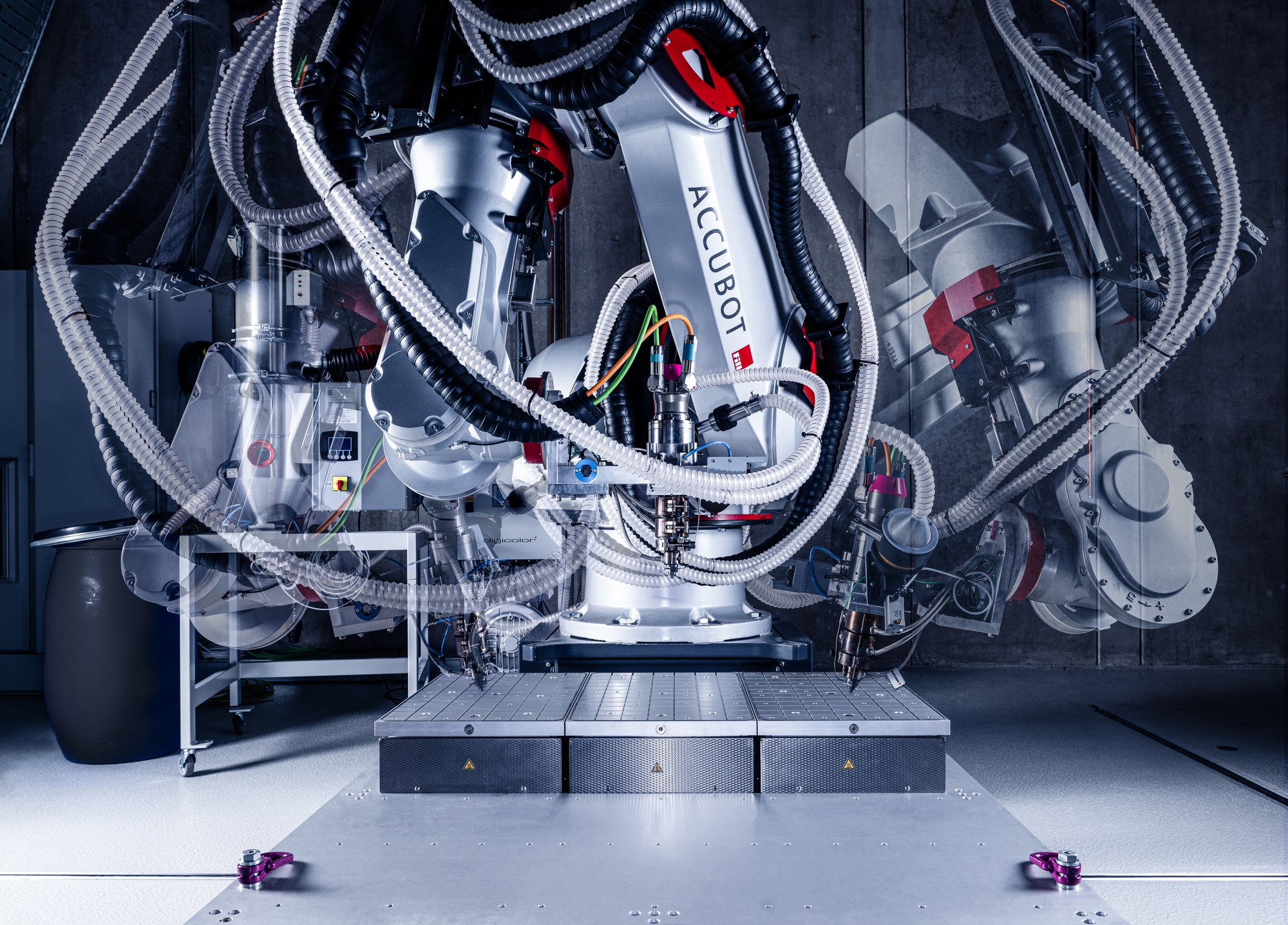

The entire process chain from design to quality-assured production is considered. Particular attention is paid to the functionalisation of materials and the additive generation of thermoplastic, continuous fibre-reinforced structures using additive extrusion. Added to this is the production of continuous fibre-reinforced semi-finished products or free-form structures based on in-situ impregnation, resulting in high-performance components made from cost-effective semi-finished products. The research work in this strategic field includes the areas of process integration, material development and characterisation, extrusion technology, quality assurance, simulation and design methodology.