Wind

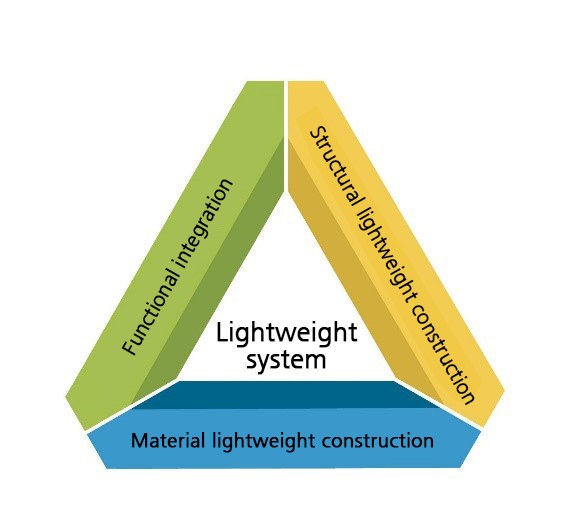

This is where the institute pools its expertise in the field of wind energy. The focus is primarily on the rotor blades of modern wind turbines, but also on niche products such as airborne wind turbines.

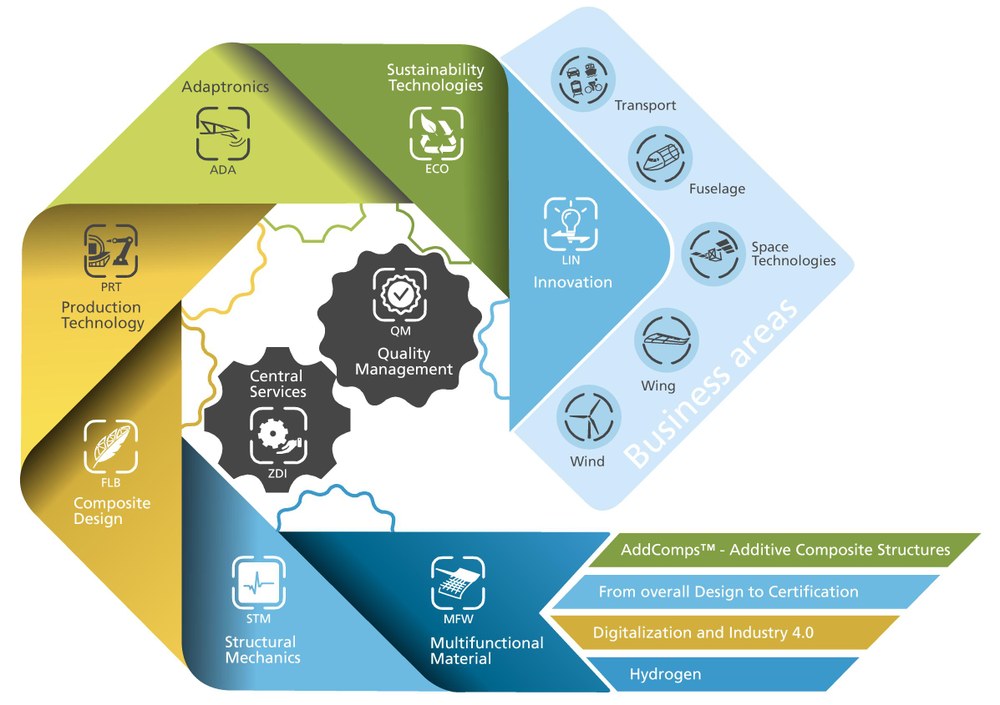

The DLR Institute of Lightweight Systems develops and tests new lightweight construction technologies for resource-saving and climate-friendly structures in the aerospace, transport, energy and security sectors. Our vision is intelligent lightweight system for an emission-free tomorrow, based on three pillars: lightweight material construction, lightweight design and functional integration. In lightweight material construction, the strengths and stiffnesses related to the material density are of decisive importance. In lightweight design, a skilful construction makes optimum use of as little material as possible and the integration of active and passive additional functions into the load-bearing structure allows further mass savings in line with the motto "Everything contributes". This turns the lightweight structure from a system carrier into a system.

Carbon fibre reinforced plastic (CFRP), one of today's most modern materials, is stronger than steel and lighter than aluminium which makes it an ideal material for lightweight construction. Lightweight aeroplanes save fuel and therefore costs, and they also emit fewer pollutants. The high-performance material CFRP is currently still comparatively expensive and its production is complex. The use of CFRP is also increasing in the automotive industry and in the manufacture of rotor blades for wind turbines. In the future, the weight of CFRP structures is to be reduced even further. Research into the material behaviour under damage and environmental influences and the integration of additional functions are intended to answer questions that are currently still open.

Our research portfolio includes high-performance materials, analysis methods for the entire life cycle, function-integrating lightweight constructions, efficient manufacturing processes for fibre composite structures on an industrial scale, adaptive structural systems and the end-to-end digitalisation of the entire process chain. We operate extensive testing facilities to clarify issues relating to material properties, stability, strength and the thermal and acoustic behaviour of components and parts. This includes a DIN ISO EN 17025 and NADCAP-certified test laboratory, thermomechanical test benches, a dynamic buckling facility and an acoustic transmission test bench. The economic manufacturability of structures is another key element of research and technology development. Winding and autoclave technology systems in Braunschweig and robotic systems for fibre deposition and highly automated RTM production as well as a research autoclave on an industrial scale in Stade form the backbone of the production technology. Developments in lightweight system construction are associated with major challenges, as there are conflicts of objectives between individual functions. These can only be resolved if the end product that the lightweight structure serves is considered: the complete aircraft, the complete vehicle. This requires intensive networking of lightweight construction with other product development disciplines such as aerodynamics and aerodynamics.

The institute forms the bridge between basic research and industrial application.

On the side of basic university research, we are connected through partnerships, lectureships and co-operations with the Technical University of Braunschweig, Otto von Guericke University Magdeburg, Clausthal University of Technology, the University of Bremen and Delft University of Technology. On the application-oriented research side, the creation of the Centre for Lightweight Production Technology (ZLP) in Stade, involvement in a customer centre with Airbus and the Virtual Product House (VPH) in Bremen and active participation in the DLR research wind farm also ensure proximity to industrial customers. The Institute is also involved in a small aircraft platform in Aachen-Merzbrück and supports the development of unmanned vehicles in Cochstedt. The Institute also cooperates with certification authorities and with research institutions worldwide as part of international research programmes. The organisation of the institute is described in more detail in the following sections.

Living science - Institute of Lightweight Systems

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.