Roboception

What is special about the technology at Roboception?

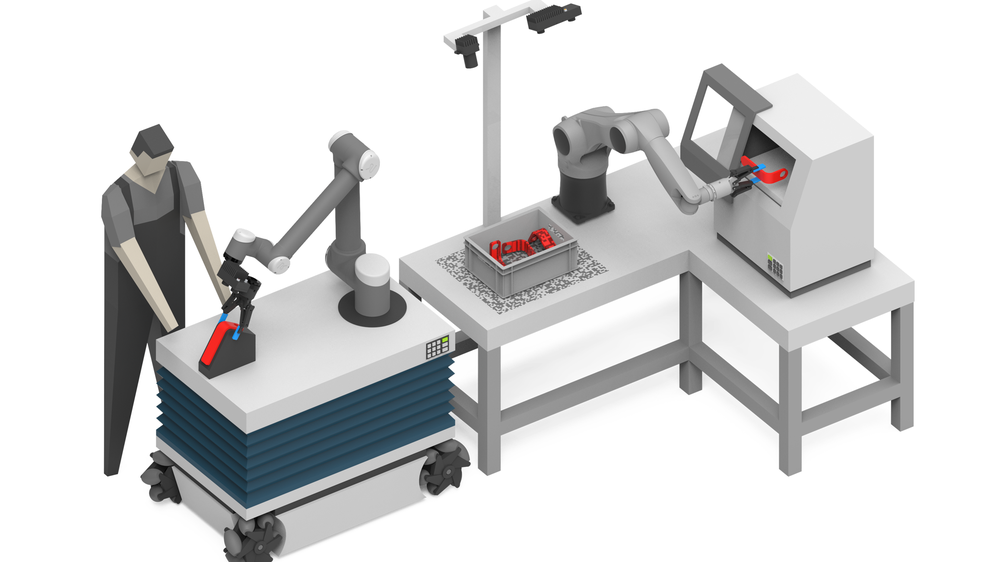

We support companies in making their production more flexible – in the areas of industrial and laboratory automation as well as logistics. Our goal is to enable robots to see and think with the help of our 3D image processing platform.

Does this flexibility relate to the current challenges in production, such as rapid changes in the production chain, customisation of products or the production of smaller quantities?

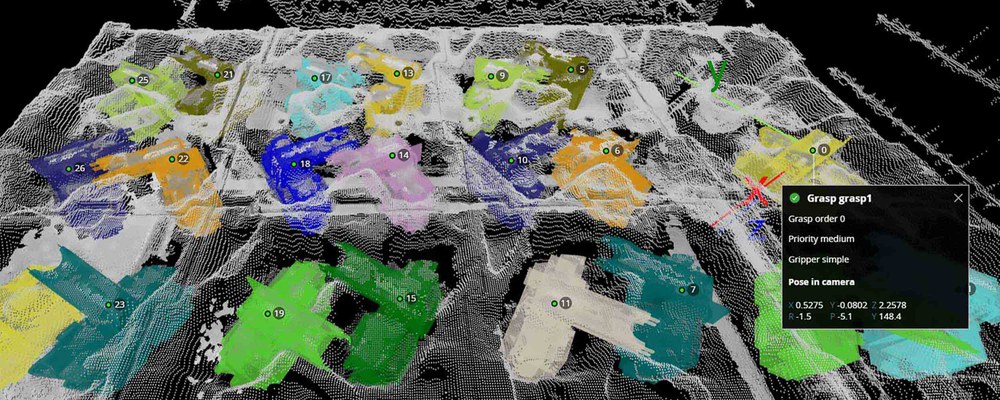

Yes, exactly. These and similar challenges in production are more relevant than ever. There are numerous areas, such as industrial automation or warehouse logistics, in which the handling of different objects in large quantities poses a challenge in terms of task transparency or fragility. Our approach is to use an AI-based image processing platform to recognise the parts, set gripping points on them and thus enable handling with robots in automation.

How did this idea come about and what role did the Institute play in it?

Our initial idea was a 3D sensor that can also be used for mobile robots, i.e. a truly flexible system. However, thanks to early feedback from the industry, we realised that most customers cannot handle 3D data, but rather need information such as target coordinates or gripping points. So we quickly learnt that – in addition to the hardware – the software and its intuitive and simple usability for non-experts is what customers need most. And that is also our unique selling point: we have changed from a hardware to a software platform and the institute has given us the opportunity to pursue and further develop our idea.

Was it clear to you from the outset that your idea offers so much added value for customers that it is worth founding a company based on it?

Yes, actually, right from the start. We founded the company in 2015 and back then, the world of industry was mainly 2D when it came to image processing. Of course, this didn't apply to our research world, but it did apply to industry. Many tasks in automation were solved with 2D cameras, 3D hardly existed. However, there are many tasks or situations, such as disorganised positioning of workpieces, i.e. taking objects out of a box or special feeding of parts, that cannot be done with 2D cameras. This realisation was our "transfer point": the industry needs commercial 3D sensors and we need to develop this idea into a product and bring it to market.

How quickly did the idea turn into a product?

We already had the basic idea when the company was founded. We gathered market feedback very early on, so it was clear to us after just 6 months what the product should be like. Then things happened quickly: 1.5 years later, in 2017 at the Hannover Messe, we launched our first product, the intelligent 3D stereo sensor rc_visard. The software has been growing and developing ever since. We were quick and – because our product is not covered by the Machinery Directive – we had regulatory advantages over other industrial sectors in terms of the approval process.

What happened next? How quickly did your company grow and what was your greatest success?

In my view, we had three important steps to success: the first major success was launching a product on the market in such a short time. Then, two years later, offering a large number of units with the first pilot customer and finally scaling the products globally with international sales partners in 2019–2020. Our team is still small: we currently have 14 employees who focus heavily on the technical side and on key customers. We have outsourced most of our sales activities and work with well-known sales partners in this area.

And what is the next big goal?

We want to continue to develop internationally and scale our portfolio to the extent that we are more broadly positioned on the market. In addition to Europe, our main markets are North America and Asia. We are currently based in Munich. For me, international scaling also includes opening further branches in America and Asia.

Roboception

Roboception

Roboception