Mobile Manipulation

Many houseworks require to manipulate tools over wide areas. The most relevant example for such a task is cleaning, where a cleaning device needs to be guided along a dirty surface. The alignment of the tool, the direction of motion, applied force and stiffness, are crucial aspects for the cleaning result but can only be taken into account when the reasoning level and the control level act jointly. Furthermore, the robot has to be positioned as optimally as possible to cover the complete region of interest.

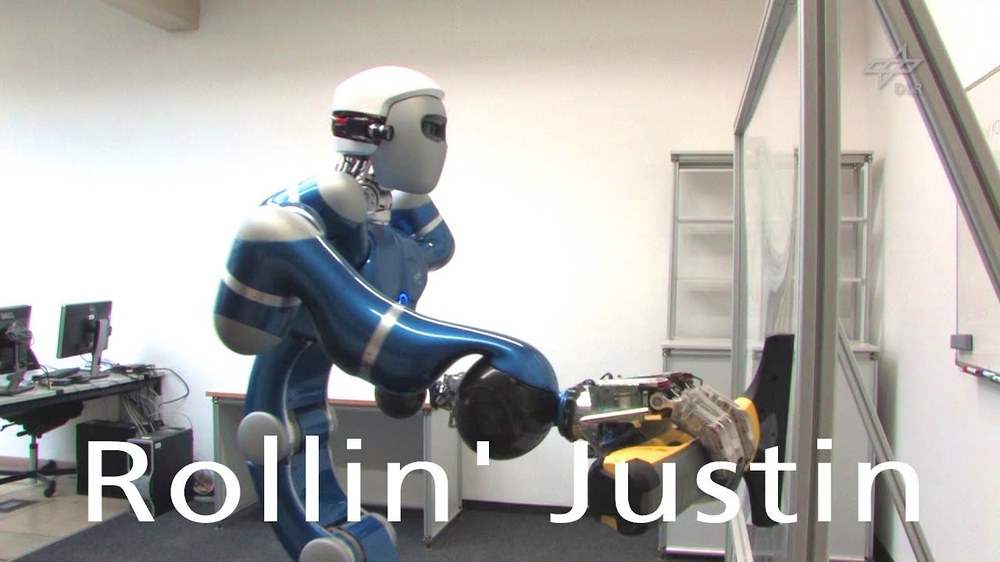

Rollin' Justin: Window Cleaning

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

Reasoning about Mobility

Capability maps which represent the reachability for robotic manipulators, in combination with Regions of Interest based on object knowledge, are used to determine the optimal base position for a given task:

- Optimizing the base position and the torso configuration.

- The decision on moving the mobile base is resolved during the geometric planning step.

- An A* planning module is applied to plan a trajectory towards the optimal base position.

Parameterizing the Control Level

Optimal positioning of a redundant manipulator guarantees higher reachability, and therefore more room to

- avoid self-collisions in case of emergency,

- apply object specific Cartesian contact forces,

- react on external disturbances on joint level.

This is accomplished by hierarchically stacking compliant control strategies by the use of null space projections.

Selected Publications

Daniel Leidner, Alexander Dietrich, Florian Schmidt, Christoph Borst, and Alin Albu-Schäffer, "Object-Centered Hybrid Reasoning for Whole-Body Mobile Manipulation", to be published in Proc. of the IEEE International Conference on Robotics and Automation, Hong Kong, China, June 2014.