SpaceMouse (1981–1993)

Why 3D motion?

In every area of technology, one can find automata and systems controllable in up to six degrees of freedom (three translational and three rotational). Industrial robots made up the most prominent category (in addition to helicopters, underwater and space vehicles), needing six degrees of freedom by maneuvering six joints to reach any point in their working space with a desired orientation. Even broader, the last few years have witnessed a dramatic explosion in the growth of 3D computer graphics.

Already in the early eighties, the first wire frame models of volume objects could move smoothly and interactively using so called knob-boxes on the fastest graphics machines available. Each of the six degrees of freedom were controlled by a separate button. Next, graphics systems on the market allowed manipulation of shaded volume models smoothly, i.e. rotate, zoom and shift them and thus look at them from any viewing angle and position. The scenes become more and more complex; e.g., with a "reality engine" of the market leader Silicon Graphics, mirror effects on volume car bodies are updated several times per second - a task that needed hours on main frame computers a couple of years ago.

Parallel to the rapid graphics development, we observed a clear trend in the field of mechanical design towards constructing and modelling new parts in a 3D environment and transferring the resulting programs to NC machines. The machines are able to work in 5 or 6 degrees of freedom (dof). Thus, it is no surprise that in the last few years, there are increasing demands for comfortable 3D control and manipulation devices for these kinds of systems.

Despite breathtaking advancements in digital technology it turned out that digital man-machine interfaces like keyboards are not well suited for people to use as our sensomotory reactions and behaviors are and will remain analogous forever.

DLR control ball, Magellan's predecessor

At the end of the seventies, the DLR (German Aerospace Research Establishment) institute for robotics and mechatronics started research on devices for the 6 DoF control of robot grippers in Cartesian space. After lengthy experiments it turned out around 1981 that integrating a six axis force torque sensor (3 force, 3 torque components) into a plastic hollow ball was the optimal solution. Such a ball registered the linear and rotational displacements as generated by the forces/ torques of a human hand, which were then computationally transformed into translational / rotational motion speeds.

The first force torque sensor used was based upon strain gauge technology, integrated into a plastic hollow ball. DLR had the basic concept center of a hollow ball handle approximately coinciding with the measuring center of an integrated 6 DoF force / torque sensor patented in Europe (1982) and the USA (1983).

In 1982-1985, the first prototype applications showed that DLR's control ball was not only excellently suited as a control device for robots, but also for the first 3D-graphics system that came onto the market at that time. Wide commercial distribution was prevented by the high sales price of about $8,000 per unit. It took until 1985 for the DLR's developer group to succeed in designing a much cheaper optical measuring system. The new system used 6 one-dimensional position detectors. This system received a world-wide patent.

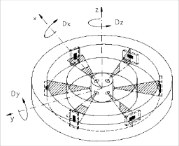

The measuring system consists of an inner and an outer part. The measuring arrangement in the inner ring is composed of the LED, a slit and perpendicular to the slit on the opposite side of the ring a linear position sensitive detector (PSD). The slit / LED combination is mobile against the remaining system. Six such systems (rotated by 60 degrees each) are mounted in a plane, whereby the slits alternatively are vertical and parallel to the plane. The ring with PSD's is fixed inside the outer part and connected via springs with the LED-slit-basis. The springs bring the inner part back to a neutral position when no forces / torque are exerted.

There is a particularly simple and unique transformation from PSD-signals U1....U6 to the unknown displacements. This measuring system is drift-free and not subject to aging effects.

The whole electronics, including computational processing on a one-chip-processor, was already integrable into the ball by means of two small double sided surface mount device (SMD) boards, the manufacturing costs were reduced to below $1,000, but the sales price still hovered in the area of $3,000. The ball's "dimension six" version was produced under our license by the company CIS. The ball was selected "product of the year" in the USA in 1988, however, only a few hundred systems were sold in those early years.

The original hopes of the developers group that the license companies might be able to redevelop devices towards much lower manufacturing costs did not materialize. On the other hand, with passing of time, other technologically comparable ball systems appeared on the market especially in USA. They differed only in the type of measuring system (and thus collided with DLR's patent). Around 1990, terms like cyberspace and virtual reality became popular. However, the effort required to steer oneself around in a virtual world using helmet and glove tires one out quickly. Movements were measured by electromagnetic or ultrasonic means, with the human head having problems in controlling translational speeds. In addition, moving the hand around in free space leads to fairly fast fatigue. Thus a redesign of the ball idea seemed urgent.

The result of a long development chain

With the developments explained in the previous sections, DLR's development group started a transfer company, Space Control, and addressed a clear goal: To redesign the control ball idea with its unsurpassed opto-electronic measuring system and optimize it:

- To reduce manufacturing costs to a fraction of its previous amount and thus allow it to approach the pricing level of high-quality PC mice, at least long-term.

- The new manipulation device would also be able to function as a conventional mouse and appear like one, yet maintain its versatility in a real workstation design environment.

The result of an intense one year's work was the European SPACE MOUSE, then called Magellan in the USA. The spin-off company Space Control started to sell Magellan especially in the European market place. In 1993, DLR and Space Control jointly approached Logitech because of their expertise with pointing devices for computers to market and sell Magellan in USA and Asia.

The wear resistant and drift-free opto-electronic 6-component measuring system was optimized to place all the electronics, including the analogous signal processing, A/D conversion, computational evaluation and power supply on only one side of a tiny SMD- board inside Magellan's handling cap. It only needed a few milli-Amperes of current supplied through the serial port of any PC or standard mouse interface. It did not need a dedicated power supply. The electronic circuitry using a lot of time multiplex technology was simplified by a factor of five compared to former control balls. The unbelievably tedious mechanical optimization, where the simple adjustment of the PSD's with respect to the slits played a central role in its construction, finally led to three simple injection molding parts, being the basic housing, a cap handle with the measuring system inside and, the small nine-button keyboard system. The housing, a punched steel plate, provided Magellan with the necessary weight for stability; any kind of metal cutting was avoided. The small board inside the cap (including a beeper) also took care of various mechanical functions. For example, it contained the automatically mountable springs as well as overload protection. The springs were optimized in the measuring system so that they no longer show hysteresis; nevertheless different stiffnesses of the cap were realizable by selection of appropriate springs.

Ergonomically, Magellan was constructed as flat as can be so flat that the human hand may rest on it without fatigue. Slight pressures of the fingers on the cap of Magellan is sufficient for generating deflections in X, Y, and Z planes, thus shifting a cursor or flying a 3D graphics object translationally through space.

Slight twists of the cap cause rotational motions of a 3D graphics object around the corresponding axes. Flying an object in 6 DoF is done intuitively without any strain. In a similar way, flying oneself through a virtual world is just fun. Touching the keys results in either the usual menu selection, mode selection or the pickup of 3D objects.

Magellan Technology Was In Space - What about the future ?

Magellan's predecessor, DLR's control ball, was a key element of the first real robot in space, ROTEX, which was launched in April 1993 with space shuttle Columbia inside a rack of the spacelab-D2. The robot was directly teleoperated by the astronauts using the control ball, but in the same way remotely controlled from ground (on-line and off line) using "predictive" stereographics.

As an example, the ground operator with one of the two balls or Magellans steered the robot's gripper in the graphics presimulation, while with the second device he was able to move the whole scenery around smoothly in 6 DoF. Predictive graphics simulation together with the above-mentioned man machine interaction allowed for the compensation of overall signal delays up to seven seconds, the most spectacular accomplishment being the grasping of a floating object in space from the ground. Since then, ROTEX has often been declared as the first real "virtual reality" application.

The graphics simulation and manipulation of 3D volume objects and virtual worlds and their combination, e.g., with real information as contained in TV images (multi-media) is not only meaningful for space technology, but will strongly change the whole world of manufacturing and construction technology, including other areas like urban development, chemistry, biology, and entertainment. For all these applications we believe there is no other man-machine interface technology comparable to Magellan in its simplicity and yet high precision. It is used for 3D manipulations in 6 DoF, but at the same time may function as a conventional 2D mouse.