DLR Light-Weight Robot II (1998–2002)

Technical Data

Parameter | Value |

|---|

total weight (incl. electronics) | |

| |

| |

| |

| |

| |

| |

| 2 position sensors

1 torque sensor |

| electromagnetic safety brake |

| |

| position, torque, impedance control |

| integrated electronics

no external rack

internal cabling |

joint space

Joint | Motion space |

|---|

1 | ± 170° |

2 | ± 100° |

3 | ± 120° |

4 | ± 130° |

5 | ± 170° |

6 | ± 130° |

7 | ± 170° |

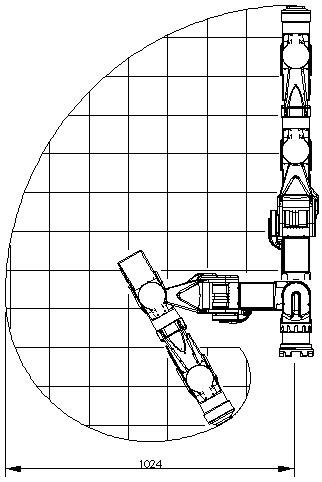

The DLR Light-Weight Robot II, firstly presented at the 2000 Hanover Fair, offered an until then unmatched ratio of payload to total mass. It could move a payload of 7 kg at full speed but weighed only 18 kg.

This extreme light-weight construction was made possible by optimizing all critical components using Finite Element Methods. Furthermore, very light gears, powerful motors and weight optimized brakes had been integrated into the robot.

Similar to the human arm, the robot had seven degrees of freedom which resulted in advanced flexibility in comparison to standard industrial robots.

All electronic components, including the power electronics, were integrated into the robot arm. In contrast to standard industrial robot systems, the LWR II required no external rack.

The integrated sensors were very progressive. Each of the Light-Weight Robot´s II joints had a motor position sensor and sensors for joint position and -torque. Thus the robot could be position, velocity and torque controlled. This resulted in a highly dynamical system with vibration damping.

Communication between the single joints was realized by an optical fiber bus system. The joint electronics were supplied galvanically isolated. The cable harness, consisting of a fiber optic cable, power supply and emergency stop circuit, was placed inside the robot.

Links