SMRS

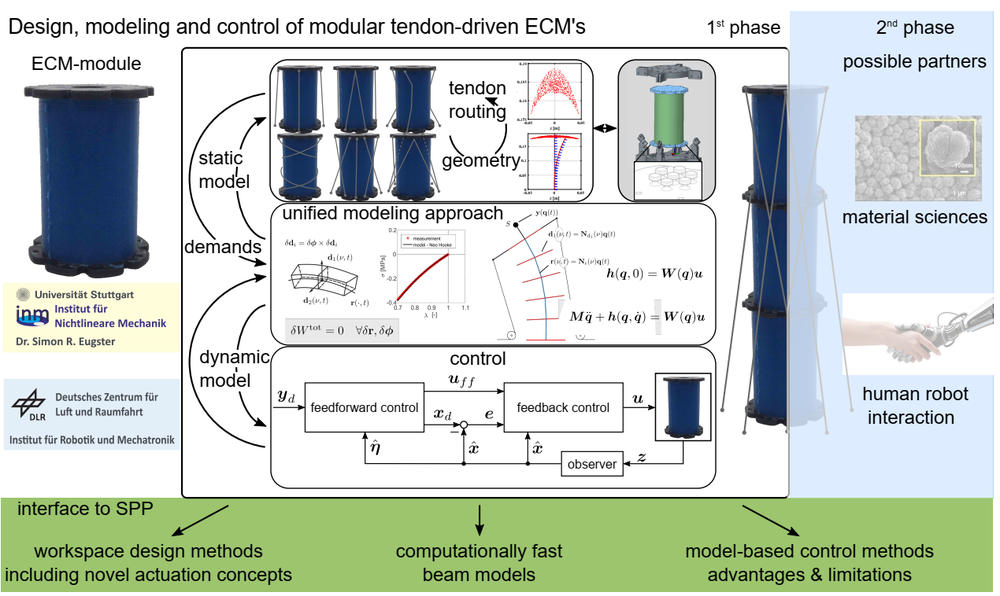

The aim of the project is to design, model and control modular tendon-driven mechanisms made out of soft materials, called modular tendon-driven elastic continuum mechanisms (ECM’s). In addition to their high dexterity, the mechanical robustness is remarkable which manifests especially in the absorption of external impacts without harming the actuators. To systematically design ECM’s composed of several ECM-modules, a unified mechanical theory for deformable and rigid bodies is required to model the mechanical behavior appearing in such soft material robotic systems. While it is certain that the workspace design requires an accurate model, the project aims also to find models which are computationally so efficient that they can be used for model-based control approaches.

First, the state of knowledge in the design, modeling and control of tendon-driven ECM’s is reviewed from literature of the robotics community. Subsequently, recent advances in the theory of nonlinear beams are discussed.

Runtime | 2019-05-01 bis 2022-04-30 |

Project partners | • Universität Stuttgart (Simon Eugster, Jonas Harsch) |

Field of Application | soft robotics |

Website | |

Funding | Schwerpunktprogramm of DFG SPP2100 „Soft Material Robotic Systems“ (Funding No 405032572) |

Project details

The emerging field of Soft Robotics is still at an early stage. Most robots are designed for a lab environment and are at a point where reliability of mechanical and electronic devices is still limited and where control concepts are in its infancy. Consequently, real applications are rather scarce. To take a step forward towards real application scenarios, we will develop a soft material tendon-driven serial manipulator. We envision the serial manipulator to be composed of stacked joint modules from the first funding period. This manipulator will serve as technology demonstrator to explore the boundaries of what is possible with soft material. With standard tests for robotic manipulators, we aim at evaluating the soft material manipulator concerning whole body deformation, dexterity, precision, repeatability, speed and robustness against external impacts. To increase the functional integration of the soft material, we investigate how to introduce hollow cavities in which the actuating tendons run freely without affecting the properties of the material. The dimensioning of these tendon channels, the tendons as well as the electro-mechanical actuators rely strongly on the possibilities to describe the physics of the manipulator. Therefore, we will set up a simulation environment for the analysis of the static and dynamic behavior of soft material manipulators. The simulation environment is characterized by the integration of tendon-actuation as well as alternative soft robotic specific actuation principles. As ultimate goal, the soft manipulator’s endeffector can follow a predefined trajectory. For the intended model-based control strategies, three topics will arise. These are trajectory generation, trajectory tracking control and state estimation of the manipulator. These topics will be particularly challenging, as corresponding methods for rigid-link manipulators are not directly applicable. As continuously distributed sensors and actuators are missing, controlling a soft manipulator means to control a nonlinear system that is highly underactuated. An additional difficulty is caused by the tendons, which actuate only unilaterally. To generate trajectories, we will work on optimal control strategies that are able to resolve these specific difficulties. For the trajectory tracking problem, we strive for a model-based feedback control strategy that allows to incorporate a feedforward control action and that exploits the favorable dynamics of the manipulator with inherently stable equilibrium configurations.Naturally, the development of the manipulator poses novel research questions concerning design, fabrication, modeling and control, which will be addressed in this project and whose answers will get us to a new generation of soft robots. (DFG - GEPRIS - Soft material tendon-driven serial manipulators)