Straight Cascade Wind Tunnel

The Straight Cascade Wind Tunnel is used for aerothermodynamic investigations on flat, vertical cascades of high, medium or low pressure turbines of aircraft engines as well as gas and steam turbines.

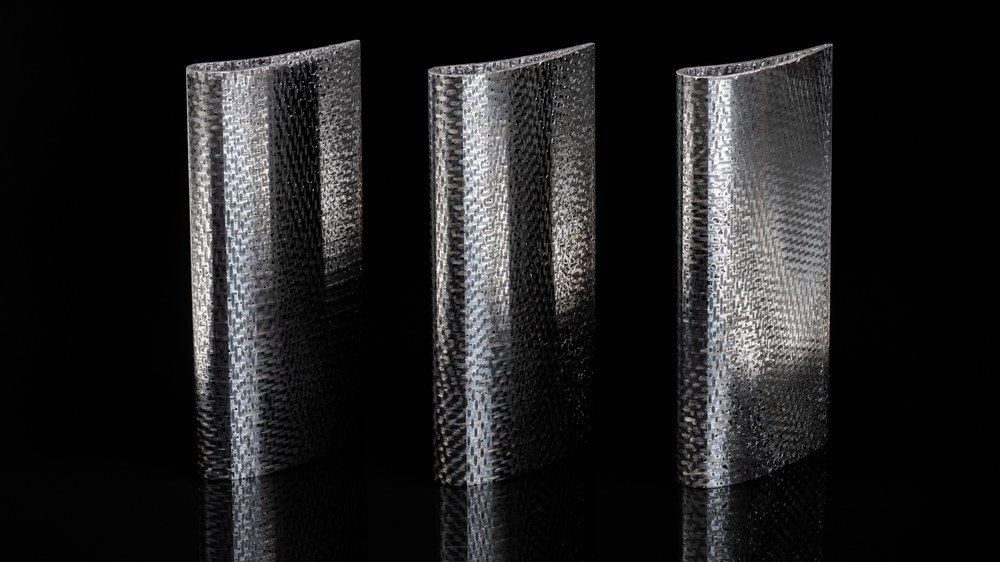

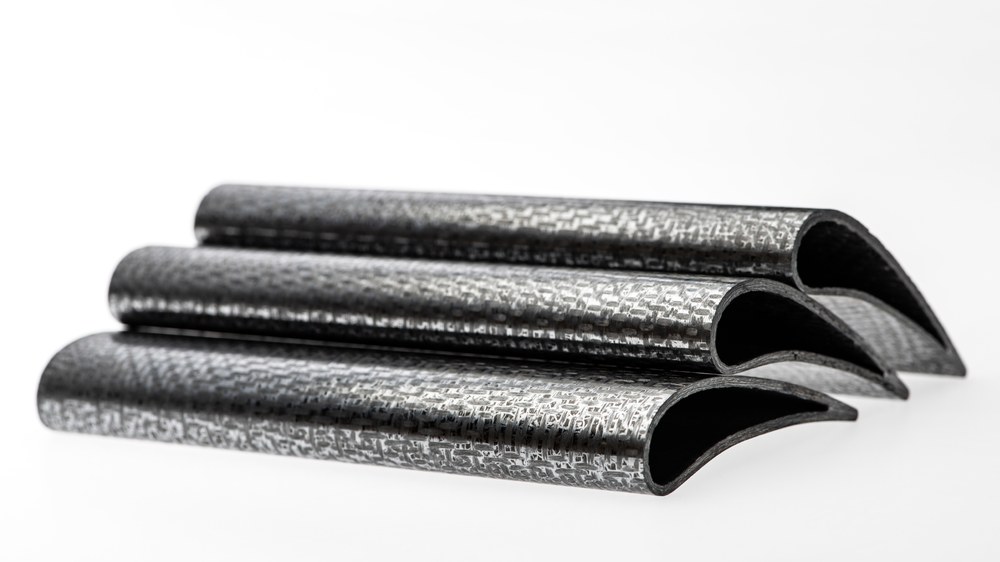

The 3DCeraTurb project focuses on the design and manufacture of a turbine vane using two of the most important new classes of manufacturing technologies and materials: Additively manufactured metals (AM) and SiC/SiC fibre reinforced ceramic matrix composites (CMC). It has two main objectives: Firstly, to establish a process chain for CMC component design, fabrication, EBC coating, wind tunnel validation and damage assessment. Second, to improve AM design and evaluation capabilities and develop a manufacturing strategy for additively manufactured guide vanes with a protective EBC coating system and an AM-compliant cooling structure design.

With the development of the manufacturing process, the individual competencies of several DLR institutes, which are mainly at the level of small models and conventional metal construction, are transferred to a realistic and engine-relevant component level.

A new turbine profile was designed based on the engine-side boundary conditions of the existing UHBR-GTF engine preliminary design from the DLR Perfect project. The complex blade geometry is a major challenge for the manufacturing process, especially for CMC materials. The up-scaling of CMC manufacturing know-how from the flat specimen to the component level is therefore a key objective of the project and a significant contribution to improving the usability of new ceramic materials with significantly higher temperature resistance in the hot gas path.

Manufacturing process information and data will be integrated into a multi-scale simulation to account for manufacturing influences and improve the overall modelling of CMC life prediction. Traceability and consistency of the data generated by the project will be ensured by a provenance data system, which is the first component of an automated process chain covering various aspects and details of aerodynamics, structural mechanics and manufacturability for both material classes.

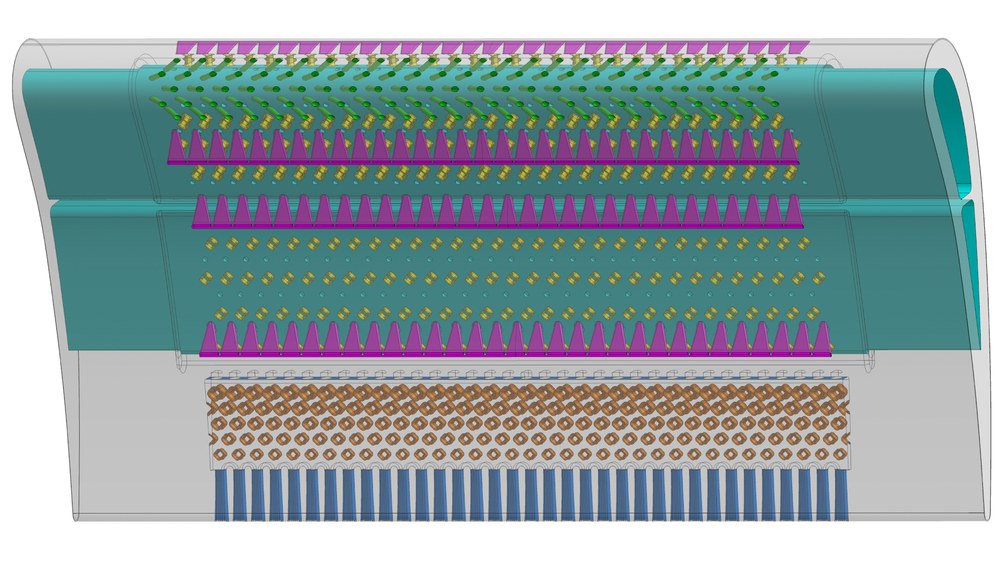

Two different cooling configurations with the same turbine airfoil geometry, i.e. a "state of the art" (SoA) geometry as a base configuration for comparison purposes and a new double-walled hybrid design [6], will be developed and compared to validate an improvement in the cooling efficiency of the additively manufactured vanes. In order to analyse and evaluate the cooling efficiency and the aerodynamic performance, the blades will be tested in the wind tunnel for plane cascades Göttingen (EGG) at TRL 4. These tests are fundamental for achieving an increased cooling efficiency of additively manufactured turbines with numerically and experimentally proven highly insulating protective layers.

The degradation mechanisms of the multilayer coating systems will be investigated in the temperature gradient test rig (TEGRA), in the thermal cycling furnace (FCT) and in the high temperature furnace under corrosive atmospheres. The project will develop and apply a multi-scale numerical method to simulate these tests and calculate the probability of failure with PyPsi.

2021 - 2024

DLR project

Turbine, materials, CMC, component design, low-emission aviation, additive manufacturing