Compressor Test Facilities

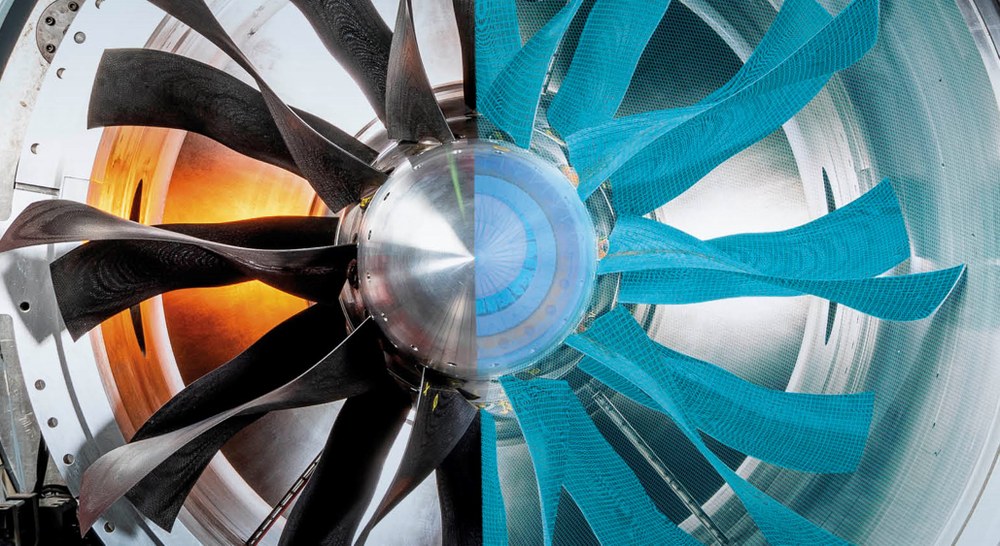

Compressor test beds are used to determine compressor maps, perform detailed flow field measurements and analyse active noise control or counter-rotating propfans.

Today, modern passenger aircraft have fans with a diameter of around three metres. Their job is to draw large volumes of air and deliver it to the main engine, as well as to generate thrust. The main engine provides the power that is converted into thrust in the fan. It is important that both the fan and the compressor can operate stably and efficiently in all flight conditions.

At the Institute of Propulsion Technology, we are working to make these propulsion and compressor systems even more efficient. To do this, we are developing and utilising software solutions for the design of the flow-guiding components in the fan and compressor, which are constantly being improved through machine learning. We use methods to develop new propulsion and integration concepts. In our department we combine numerical design, simulation and optimisation of fan and compressor components with practical experiments on our compressor test facilities.

In our Fan and Compressor Department, we are continuously developing our expertise and capabilities in the research and development of compressor concepts. We develop methods for aerodynamic prediction and geometric adaptation of inlets, fans, propellers and compressors in both axial and radial designs. We also work on optimisation algorithms and use machine learning. These methods are used in national and European research projects to evaluate these components holistically and to develop them from the initial concept to the finished product. In recent years there has been a trend towards a very detailed approach, both in terms of the real geometric aspects and the integration of the engines into the aircraft, the consideration of boundary layer induction in the intake and fan, and the application of high-precision computational methods as early as the design phase.

On our three test rigs, the multi-stage twin-shaft axial compressor test bed, the transonic cascade wind tunnel, the inter compressor duct and the radial compressor test bed, we measure various gas turbine components, from the determination of their key aerodynamic parameters and characteristic fields to the detailed recording of three-dimensional flow fields. Our investigations range from basic transonic lattice aerodynamics experiments to highly complex multi-stage compressor rig experiments.

System design

Method development: from preliminary design to 3D design

Process automation, automated optimisation

Machine learning, AI

Multidisciplinary design

Multistage axial and centrifugal compressors

Open and shrouded thrust generators

Aircraft integration, BLI and inlet perturbation

Experimental research

Operation of the test bed and set-up of the rig