Scientific Publications

On the DLR publication server elib you can find scientific publications of our department.

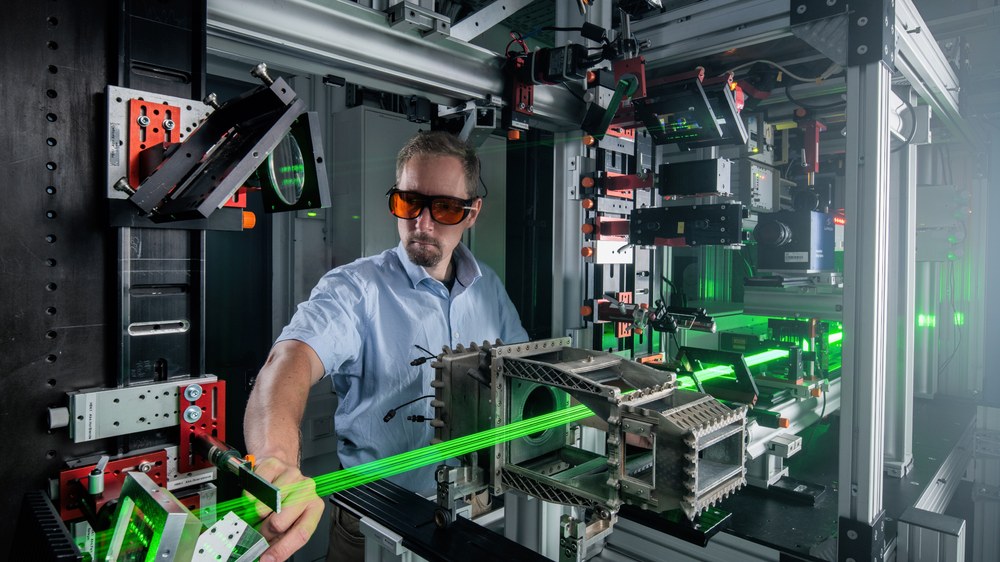

We develop and operate high-resolution laser-optic measurement techniques for the analysis of aerothermodynamic processes in engine and power plant components and for the validation of computational methods. The development aims include optimising the accuracy of individual measurement methods as well as adopting and integrating new metrological approaches. Measurements are carried out both at the Institute's test facilities and under external contracts with industrial and academic partners. A particular challenge is always to adapt our measurement techniques to the different test bed environments in which they are used on turbomachinery components under real operating conditions.

The engine measurement department has many years of experience in the design of laser-optic measurement equipment. This includes the design and manufacture of probes for high-pressure and high-temperature applications, fibre-optic assembly and prototyping. For interdisciplinary technology transfer, the engine measurement department actively uses interfaces with the measurement and automotive industries, for example, and is involved in wind tunnel applications and the development of high-power LED technology.

With our laser-optical measurement methods, we contribute to a better understanding of the aerothermodynamic operating behaviour of engine and power plant components and provide extensive databases with the measurement results, which are used to validate numerical models and simulation tools. Our aim is to bridge the gap between conventional component testing and the predictive capabilities of modern simulation environments.

Our department focuses on two main areas: flow field measurement techniques and spectroscopic methods.

Flow field measurement techniques: This area primarily includes methods for measuring flow velocities and visualising complex flow phenomena. These include:

These techniques are mainly used to analyse flows in compressors and turbines.

Spectroscopic methods: We use various spectroscopic techniques to investigate thermodynamic quantities and chemical processes in combustion chamber flows:

Depending on the research question, we combine different methods to measure several flow quantities simultaneously.

Newer measurement methods used in our research include specialised systems such as MA-µPTV (micro airborne particle tracking velocimetry) for measuring local wall shear stresses and near wall turbulence, EBIV (event-based imaging velocimetry) based on small, event-based imaging systems for velocity measurement, and endoscope optics specially developed for high-pressure combustion chamber diagnostics in full-scale test environments.

Experimental development and application of optical measurement methods to achieve the highest possible accuracy for the further development of engines and engine components, as well as for the validation of computational methods.

Component measurements on the institute's own test facilities (compressor, combustion chamber, turbine)