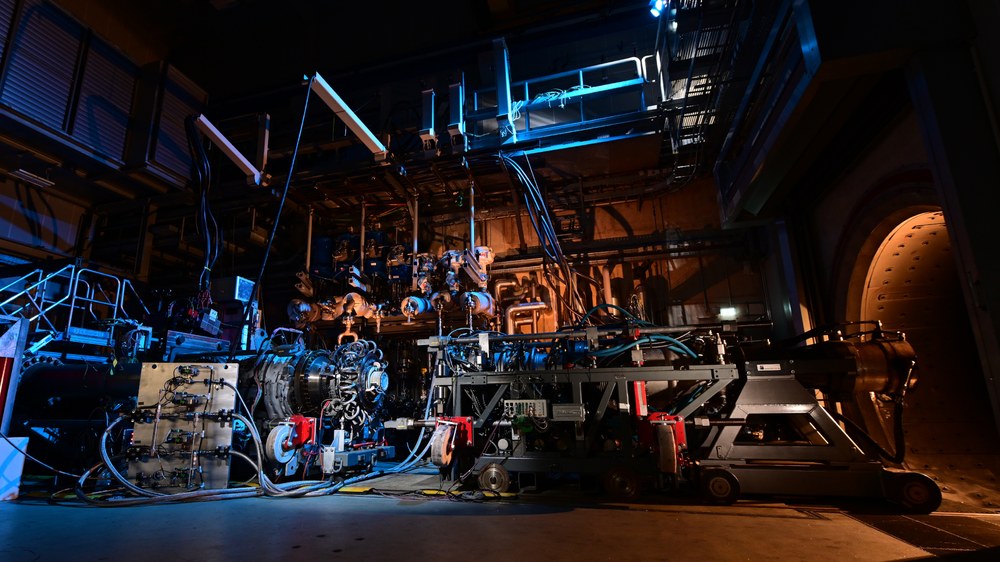

High-Pressure Combustor Test Facilities

We operate a number of high pressure combustor test beds for testing new gas turbine technologies from early stage to high technology maturity with direct industrial application relevance.

Rolls-Royce / Stefan Wriege

The next generation of gas turbines must meet society's demands for environmental protection. This means that future products must reduce emissions and have high efficiency. In order to address these technological challenges in gas turbine design, the Combustor Testing department conducts full-scale industrial trials. In this way, we support the development and transfer of new combustor technologies to industrial applications.

The Institute of Propulsion Technology operates several high-pressure combustor test beds at the DLR site in Cologne, which are used for both basic and applied research. They have a flexible operating licence geared towards research and development and enable the rapid set-up of next-generation experiments and the generation of scientific knowledge for tomorrow's gas turbine technology.

Our test bed infrastructure allows the validation of component technologies under conditions of full-load exhaust gas pressure and temperature. The modular technical equipment gives the combustor designer degrees of freedom to modify pressure, temperature and mass flow independently of the gas turbine characteristic. The infrastructure allows for project-specific additions and technological adaptations and is also capable of using liquid and gaseous fuels of different compositions for both aviation applications and stationary combustors.

The equipment on the test beds is being developed in line with the latest research and development work at the institute and offers maximum availability for gaining new insights into combustion chamber design up to an outlet temperature of 2200 K. Our aim is to determine validation results with high demands on reproducibility in experiments up to 40 bar combustion chamber pressure.

In this way, we are accelerating the development process for combustor technology and helping to bring the next generation of technologies to market as quickly as possible. To achieve this, we have a skilled team of experienced, highly motivated and qualified people with extensive expertise.

Our high-pressure combustion chamber test beds are used for DLR's own research, for research within joint projects and in cooperation with partners of the Institute of Propulsion Technology.

We will be happy to advise you if you are interested. Please get in touch with us.