Structures

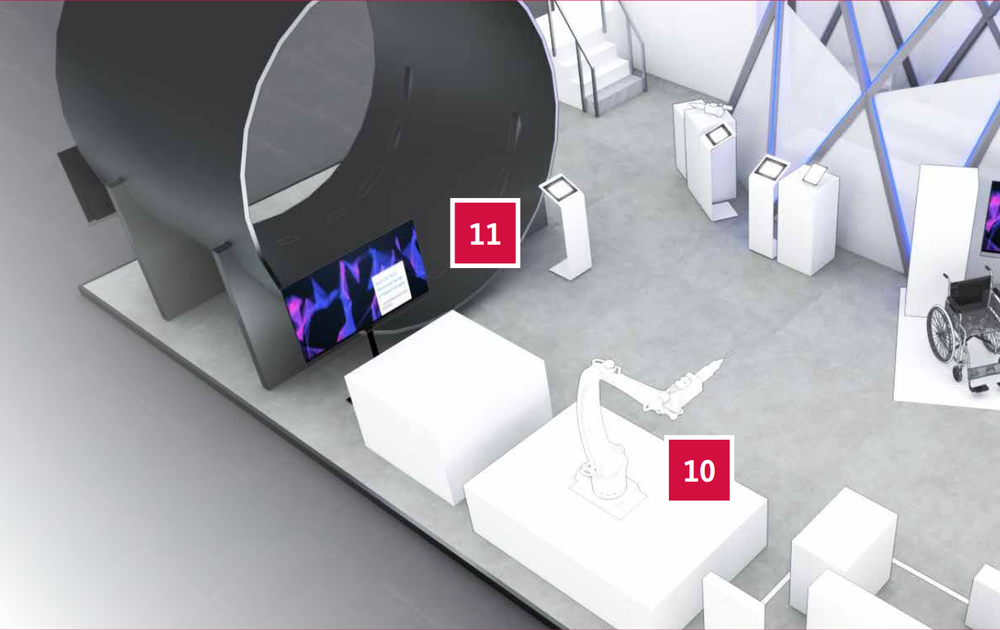

10: Intelligent Guided Vehicle (iGV) for autonomous component transport and mobile component processing & inspection

Increasing production rates, a high degree of customisation and product variations as well as limited production space pose challenges for today's manufacturing and assembly processes and will require flexible, adaptable technologies in the future, especially as alternatives to stationary special machines. One approach here is autonomous, mobile platforms for component processing and transport.

The intelligent, driverless transport system iGV developed by FFT Produktionssysteme on the basis of the LuFo projects MBFast18, MFlex2025 and UniFix, among others, fulfils even the most demanding requirements in this context. Equipped with state-of-the-art technologies in the areas of control, sensors, task planning, networking and safety technology as well as optional robotics and various end effectors, it enables highly automated, smart and flexible production processes.

In combination with FFT lightweight construction technologies, such as FibreTec3D, solutions for transporting and processing components, especially those made of fibre-reinforced materials, with large dimensions and complex and varying geometries can be implemented in a resource- and cost-efficient manner. Modern image- and laser-based systems, such as the FFT AI-Panel, FFT VisionView or FFT BestFit, which are also equipped with artificial intelligence for data processing and optimisation, also enable efficient positioning and checking of production and assembly quality.

Further information can be found at www.fft.de

FFT Produktionssysteme GmbH & Co. KG

FFT

FFT is one of the leading global providers of automated production and test systems for various industries, such as automotive, aerospace and energy. As a high-tech company, FFT has a large technology and product portfolio, from image processing and laser technology to lightweight construction and bonding technologies. Continuous innovation ensures that future flexible manufacturing systems are based on intelligent solutions.

11: Study: Welding of a fuselage section

This study shows a fuselage section whose longitudinal seams are completely welded. All components of the usual riveted joint (overlap, connecting elements, sealant and titanium) are omitted. The innovative aluminium sheets used here significantly improve processing. The technology also enables weight savings, process time reduction and excellent recyclability of the longitudinal seam.

Further information can be found at https://www.airbus.com/en/airbus-aerostructures

Airbus Aerostructures

Airbus Aerostructures is pioneering highly efficient and sustainable aircraft production at the heart of Airbus. With around 11,000 employees, we combine technology leadership and innovation with state-of-the-art and efficient aircraft production to prepare for the construction of hydrogen-powered aircraft.