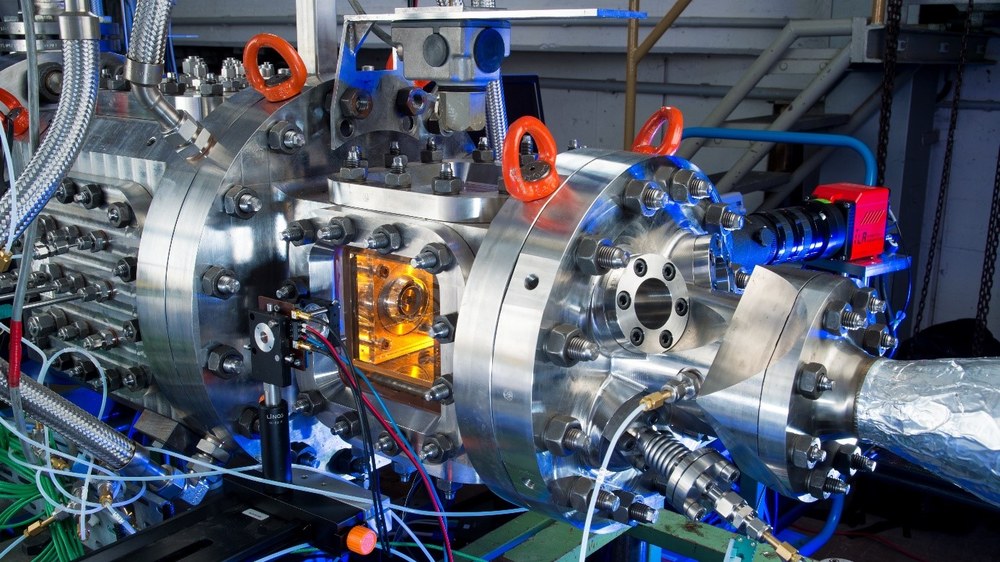

Pre-heated air under pressure is fed to an atomiser via an electric air heater which can operate at temperatures up to 850 K. The liquid fuel, usually paraffin, is fed through pipes into the measuring section and to the atomiser where it is atomised. The atomisation process can be characterised using optical measurement techniques in the measuring section, which is optically accessible from four sides. The high pressure windows allow the use of a wide range of laser optical measurement techniques. The fuel-air mixture is catalytically post-combusted in the exhaust tract.

The test rig is used to generate basic experimental data on the atomisation process of gas turbine burners, which is used in the design practice of numerous European engine manufacturers. In addition, the data sets generated are used by DLR and various research partners to validate numerical modelling approaches.

Characterstics

Technology Readiness Level 2-3

Real pressures and temperatures

Use of original fuels

Visually accessible test bench

Research Topics

Optical investigation of atomisation processes under aeronautical operating conditions:

Flow field near the burner, droplet size distribution and velocity, spray placement, transient droplet velocities, 3D spray trajectories, fuel vapour distribution

Provision of experimentally determined fuel spray boundary conditions for combustor simulations

Testing of SLM burners and combustor elements

Measurement Technology

Particle Image Velocimetry (PIV)

Laser Doppler Anemometry (LDA)

Phase Doppler Anemometry (PDA)

Kerosene LIF

Mie Scattering

Tomographic shadowgraph

Tecnical Data

Static pressure | 25 bar |

Preheating temperature of the air | 850 K |

Air mass flow | 1,5 kg/s |

Fuel mass flow | 10 g/s |

Catalytic post-combustion |