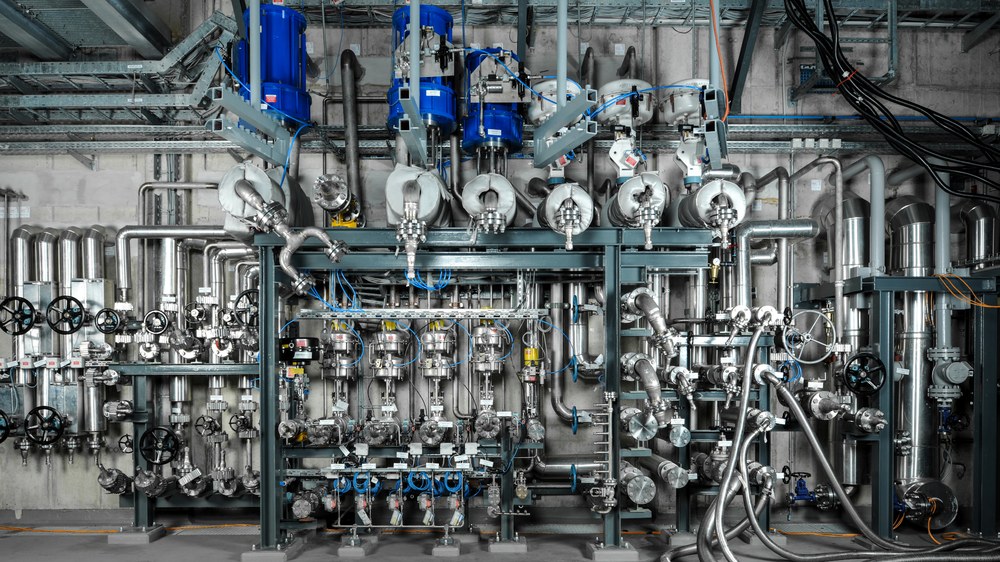

Due to its dimensions, the High Pressure Combustor Test Facility 5 (HBK 5) offers the possibility to validate combustion chamber component technology up to a thermal output of 125 megawatts. As part of DLR's research collaboration, experiments are carried out with industrial partners to simulate real-cycle process parameters for pressure and temperature. The design of the test facility allows synergy effects in the experimental development of flying and stationary CO2-free gas turbines. This includes full-ring combustors and single combustors from engine design. Component testing provides the developer with added technological value to vary inlet conditions and air and fuel mass flows with a high degree of flexibility, independent of the overall system.

Full-scale testing with original combustors in a component test, unrestricted by compressor and turbine operating windows, is an accelerator in the development process. The existing infrastructure for the use of future fuels such as hydrogen and Sustainable Aviation Fuels (SAF) increases the speed of innovation from technology development to market maturity. The globally unique HBK5 research platform accelerates the time-critical transformation of the energy system and aviation towards CO2 freedom.

Characteristics

True-to-scale tests with original combustion chambers

Connection to existing infrastructure for the use of hydrogen and SAF

Research Topics

Aeronautics:

High Pressure Full Annular (HPFANN) Experiments

Energy:

Validation of sequential Combustion

Measurement Technology

Minimally invasive optical measurement technology through the use of cooled high-pressure probes (in-house technology)

Tecnical Data

Performance | 125 MWth |

Combustion chamber pressure | up to 40 bar |

Preheating temperature of the main air | up to 700°C |

Air mass flow | up to 70 kg/s |

Fuel mass flow | up to 2,5 kg/s (CH4, Kerosin), 500g/s (H2) |