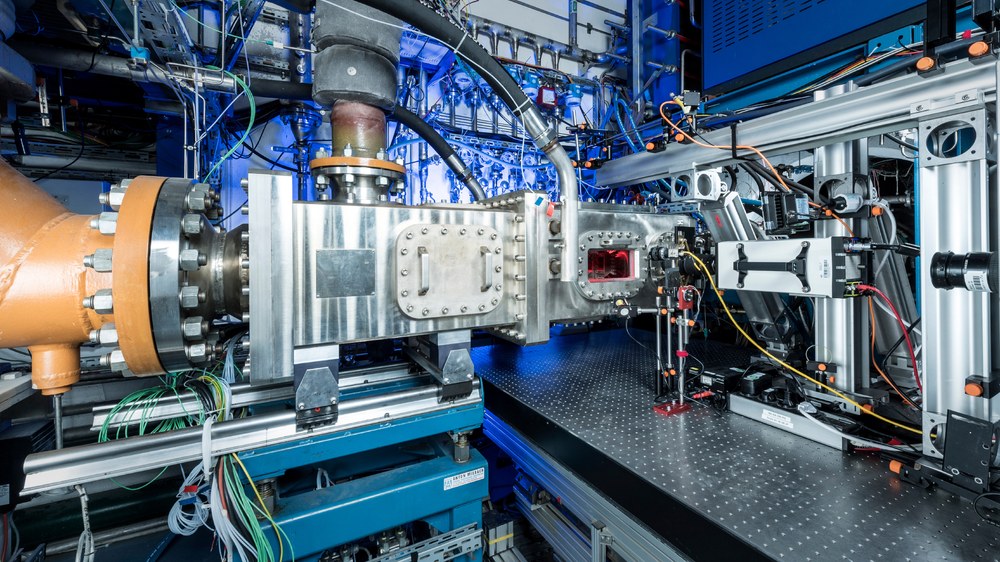

The large-scale high-pressure combustor test facility 1 (HBK1) system forms the supply and operating environment for various measuring sections. These are designed to be able to test full-size gas turbine burners under realistic operating conditions. Thus, the HBK1 is operated with single-burner combustion chambers as well as with multi-burner sectors. All combustion chambers not only have a geometrical similarity to the original operating environment, but also the distribution of cooling, mixed and secondary air analogous to the engine combustion chamber. In addition, the combustion chambers have full optical accessibility. This makes it possible to use optical measurement technology to record the processes and interactions in all zones and areas of the combustion chamber without influencing the reacting flow field.

Due to the possibility in the HBK1 to control all air and fuel mass flows, as well as the pressure independently of each other, a wide, comprehensive operating field including off-design points can be covered and controlled. New technical innovations to reduce pollution in aviation can be investigated very quickly in a TRL-4 environment in HBK1. This is made possible by the use of modular combustion chambers manufactured using the laser melting process (SLM).

Characteristics of the test bed

Technology Readiness Level 4

Static pressure up to 25 bar

Preheating temperature of compressed air up to 900 K

Air mass flow preheated up to 4.5 kg/s. Up to 10 kg/s of preheated and cooling air in total

Variable distribution of preheated air

The following are used: single-burner combustion chambers, multi-sector combustion chambers

Full optical accessibility in all combustion chamber zones

Liquid and gaseous fuels incl. hydrogen

Reasearch topics

Fuel treatment, atomization, evaporation, dispersion

Pilot/main burner interaction, flow field, stabilization, heat release

Pollutant formation / soot production

Mixing of secondary and mixed air

Burner-Burner Interactions

Investigation of combustion chamber exit parameters (=turbine inlet)

Burnout

Thermoacoustic stability

Use of SLM – manufactured combustion chamber components and combustion chambers

Mesaurement technology

Particle Image Velocimetry (PIV)

Laser Doppler Anemometry (LDA)

Phase Doppler Anemometry (PDA)

Kerosene LIF

Mie scattering

Laser-induced incandescence (LII)

Tecnical Data

Static pressure | 25 bar |

Preheating temperature of the compressed air | up to 900 K |

Air mass flow | up to 4,5 kg/s preheated up to10 kg/s cooling air total |

Liquid fuels | Kersoene, SAF |

Gaseous fuels | Hydrogen, methane |