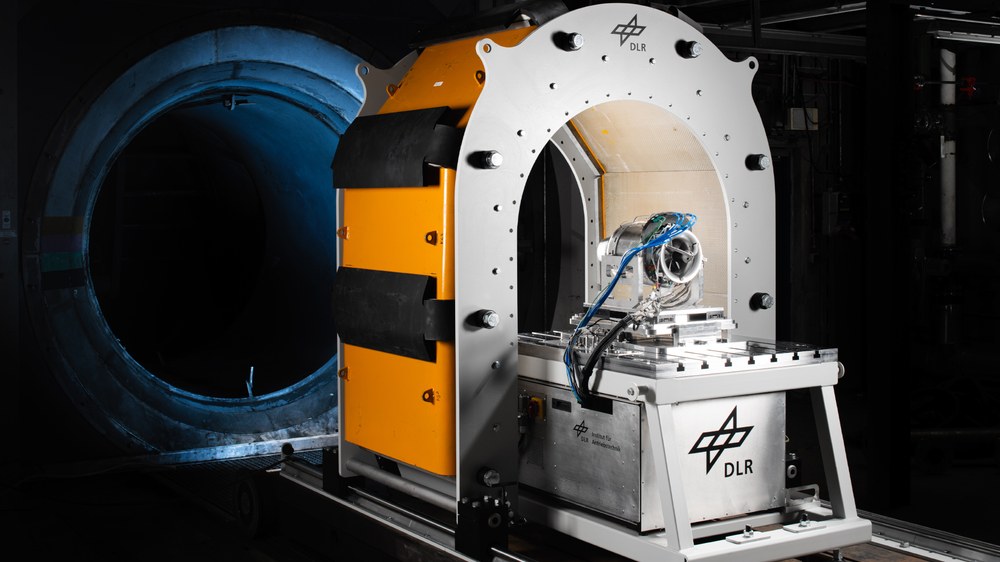

The prototype laboratory offers a wide range of options for the development and validation of new aircraft engines and technologies. Its modular design allows it to be adapted to different engine configurations and test setups - from conventional turbomachinery to to hybrid-electric turbo propulsion and alternative fuels.

The engine test facility with thrust classes up to 6 kN is part of DLR's Future Propulsion Test Facility and is therefore integrated into a versatile test rig infrastructure. Various resources such as different fuels, compressed air and water supply, electrical power and extensive measurement technology are available. In addition, an experienced team is available to carry out projects efficiently. The prototype laboratory benefits from its close connection to the DLR Systemhaus Technik, which means that planning, simulation and feasibility studies for development, production and assembly can be seamlessly coordinated.

Researchers and engineers can work together to develop new ideas and test their feasibility. The laboratory also serves as a valuable training tool for engineering students, who can deepen their knowledge and gain valuable insights into aviation technology through practical experience with real drive systems.

Application examples

- Use of different fuels: Research and evaluation of different fuels for aviation propulsion systems to develop more sustainable propulsion solutions.

- Small scale testing of innovative components: Rapid development and evaluation of prototyped components in the overall engine system.

- Validation of methods based on experimental investigations: Experimental validation of aircraft engine analysis and optimisation methods for the further development of more accurate computational methods.

- Engine measurement: Detailed measurement of engines to assess performance, efficiency and key operating parameters.

- Demonstration of new manufacturing processes: Use of components in a real environment to verify and test innovative manufacturing processes for aviation components.

- Generation of data sets for the development of new analytical methods: Generation of data sets for the development and validation of new analytical methods and the use of artificial intelligence.

If you are interested, we will be happy to talk about the possibilities of using the prototype laboratory for your research and development. Please contact us.