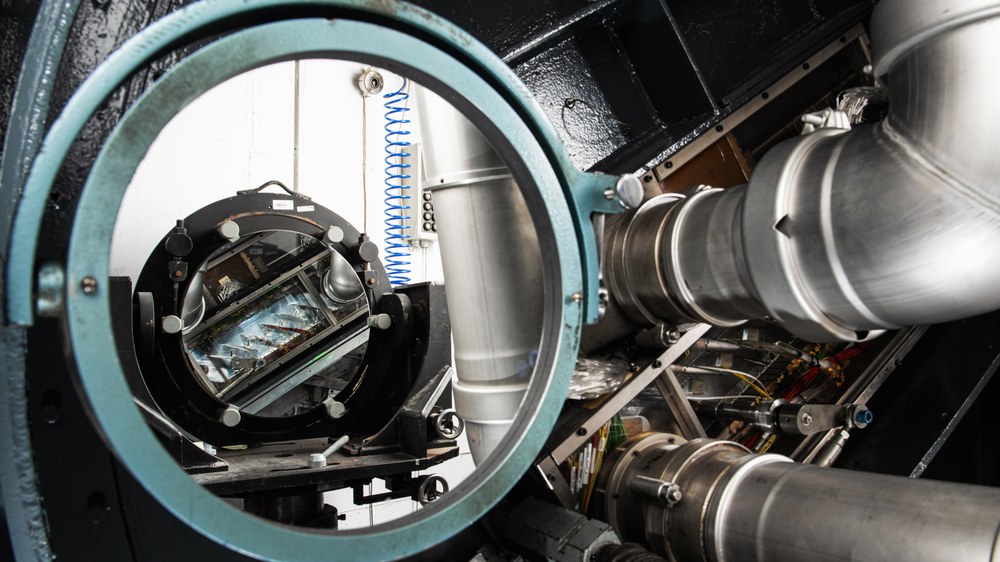

The main advantages of studying on flat grids are the very good metrological and optical accessibility and the possibility to study aerodynamic and geometric parameters independently of each other, which is not possible on the real machine. The wind tunnel has a test section with variable channel height and allows inflow Mach numbers up to Ma1 = 1.4 with very stable operating conditions, especially at sonic inflow (Ma1 = 1.0). The test facility is operated in a closed loop, allowing the Reynolds number to be varied independently of the Mach number, with total pressure and total temperature being adjustable independently. This versatility is made possible by DLR's centralised air supply, which gives the facility a unique level of performance. This means that investigations can be carried out under conditions close to the Mach number and Reynolds number, which is particularly important for turbomachinery experiments. The inflow turbulence is extremely low at only 0.6-0.8%, but can be increased to over 4% by the selective use of different turbulence grids.

Characteristics

Technology Readiness Level 3-5

Metrological and optical accessibility

Investigation of aerodynamic and geometric parameters independently of each other

Research Topics

Validation of flow computational methods

Development and verification of new profile concepts

Qualification of new measurement methods under turbomachinery flow conditions

Fundamental investigations of turbomachinery flow phenomena

Technical Data

Inflow | |

Mach number | 0,2 – 1,4 |

Reynolds number | 1,0 x 105 – 2,0 x 106 |

Total pressure | 0,1 bar – 1,3 bar |

Total temperature | max. 310 K |

Turbulence level | 0,6 - 4,0 |

Grid | |

Mounting angle | 80° - 160° |

Duct height | 15 mm - 300 mm |

Blade hight | 168 mm |