Unsteady aerodynamics in turbomachinery

The flow in turbomachinery is characterised by many unsteady effects, particularly in the flow around the blades. The wake from each row of blades meets the next row of blades further downstream. This affects both the aerodynamic quality and the vibration and acoustic emissions in the individual engine components. Time-resolved measurements of velocities and wall pressures give us a clearer picture of the transient interactions.

The Department of Engine Acoustics at the DLR Institute of Propulsion Technology has carried out numerous investigations, the results of which provide a valuable database for the development of acoustic prediction tools. This makes it possible to predict the sound radiation at the design stage of new engine concepts. This information can be used to confirm the successful design of new compressor concepts and to validate numerical flow simulations.

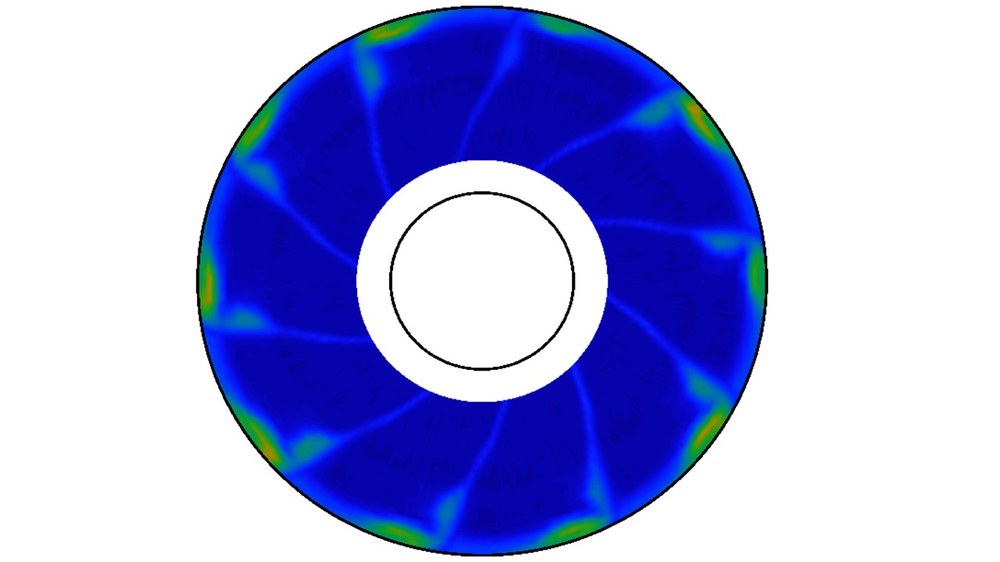

To do this, we measured the transient flow fields of modern fan module concepts in detail. The fan is the first externally visible compressor stage and an essential element of thrust generation in aircraft engines.

In national and international projects, measurements have been carried out on both conventional fan arrangements and arrangements with two counter-rotating fan rotors. In addition to the unsteady flow fields of modern fan designs, extensive aerodynamic and acoustic measurements have been carried out under the influence of inlet perturbations. Unsteady flow phenomena are responsible for noise generation. The local time-resolved turbulence variables can be determined from this measurement data.