Participation in the 2024 Rolls-Royce German UTC Review in Dahlewitz

Rolls-Royce Deutschland

New combustor concepts, advanced emissions measurement and validation, the interaction of combustor and high-pressure turbine and aerodynamic and aerothermal aspects of the high-pressure turbine were the main topics of this year's Rolls-Royce German UTC Review in Dahlewitz, Germany, in which the German Aerospace Centre (DLR), the German Rolls-Royce Research and University Technology Centres (UTC) took part. The DLR Institute of Propulsion Technology presented the latest results from its combustor and turbine departments.

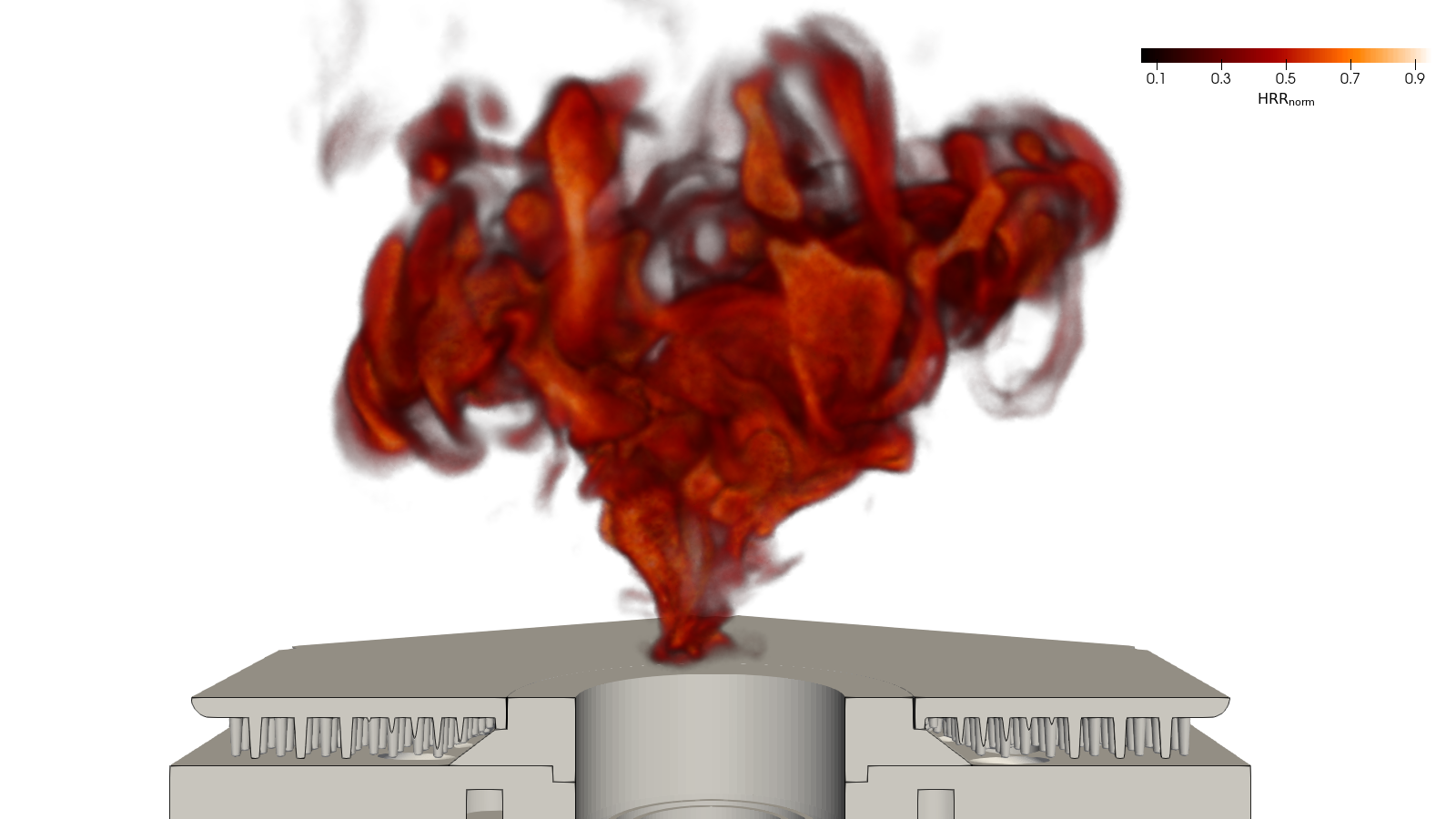

Flexible burner concepts for hydrogen and liquid fuels

Hydrogen burners and dual-fuel injectors, which can run on both liquid fuels and hydrogen, are considered important milestones on the road to climate-friendly aviation. The DLR Institute of Propulsion Technology and Rolls-Royce Germany are investigating these new technologies using optical measurement techniques on various DLR combustion chamber test rigs. The experiments are accompanied and supported by numerical flow simulations. At this year's review, Dr Simon Gövert presented a design tool developed for burner design and demonstrated compliance with design parameters using experimental and numerical results. He also presented the use of reactive flow simulations for relevant hydrogen burners to validate the TRACE CFD solver by comparison with reference data from corresponding measurements. The work is carried out within the Lufo funded projects WotAn and TeteAnt-H2 and the EU project CAVENDISH.

Improved measurement conditions on the Next Generation turbine test bench

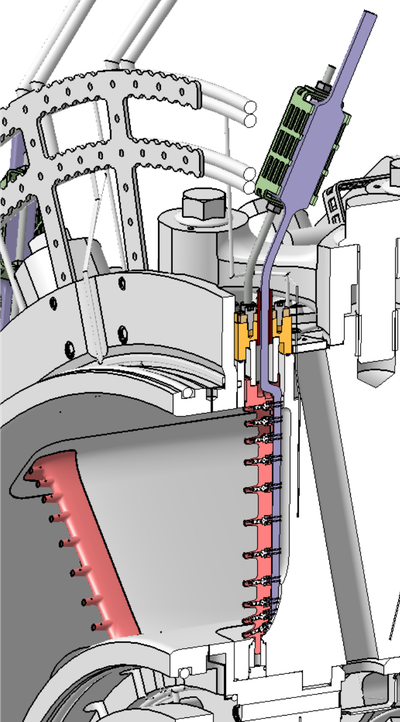

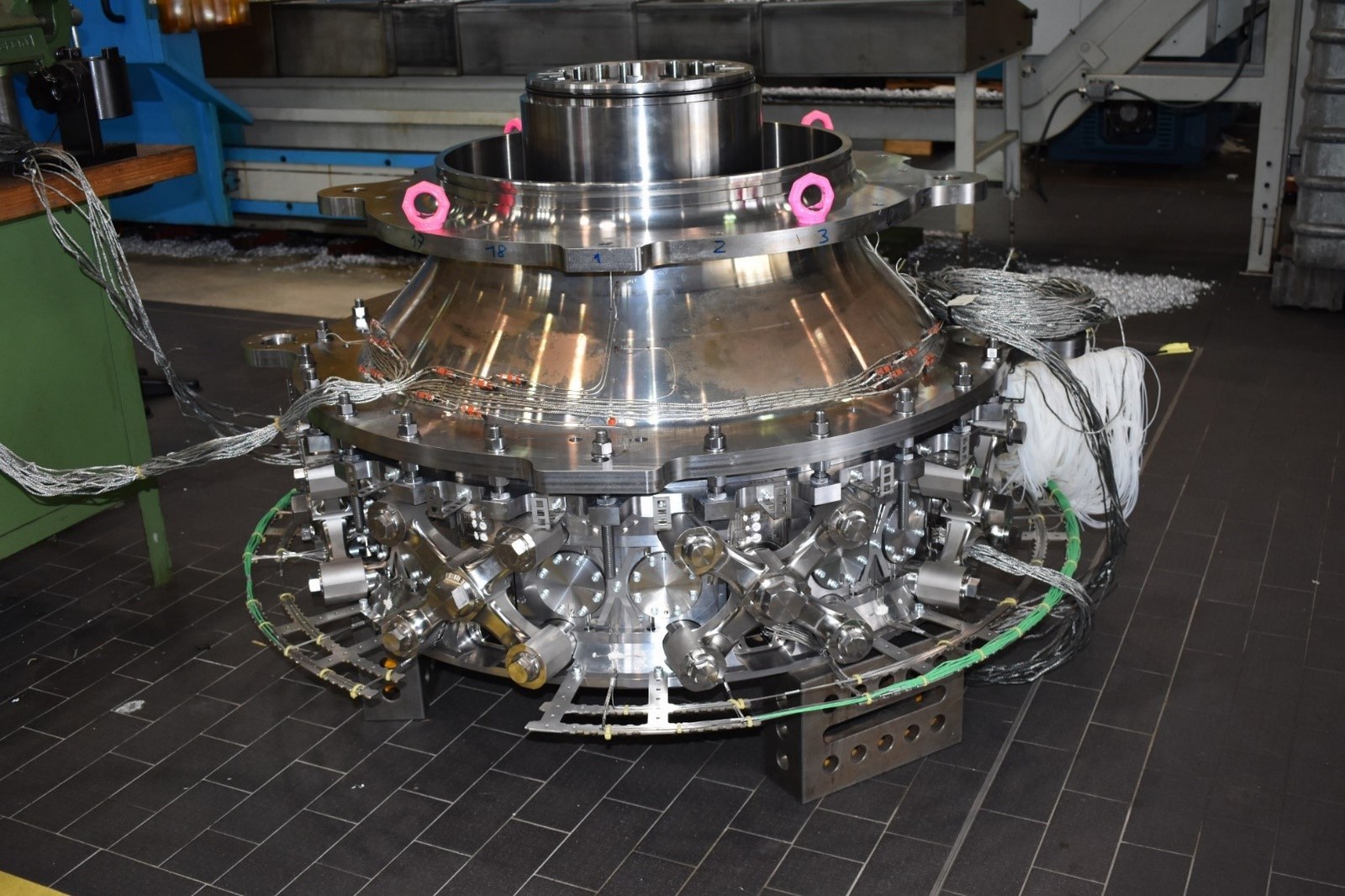

The Next Generation Turbine Test Bench (NG-Turb) at the Institute of Propulsion Technology in Göttingen is used for aerothermodynamic tests on high-efficiency high-pressure turbines of aero engines and gas turbines and is continuously developed to enable realistic tests.

Dr Andreas Pahs presented the latest measures implemented as part of the EU Transition project to further improve the quality and quantity of measurements on the test facility. To this end, the researchers have added new components to the inlet section of the turbine rig to enable a rapid ramp-up to the desired thermal operating conditions, and have developed new probes for the turbine inlet to improve the accuracy of temperature measurement.

In subsequent measurement campaigns, the scientists investigated the effects of a combustion chamber-like flow on the turbine. This allowed the influence of the inhomogeneous flow on the efficiency of the turbine to be determined. In the current LuFo-funded TeTeAnt-H2 project, the influence of turbulent flow at the turbine inlet is also being analysed. By modifying the combustor simulator, the degree of turbulence will be made representative of real engines.

About the Rolls-Royce / DLR / Research and University Technology Centres (UTC) Review

With the Research and University Technology Centres (UTC), Rolls-Royce has established a worldwide network of universities and research centres. Each UTC stands for cutting-edge research in a key technology and together they cover a broad spectrum of technical disciplines. The DLR Institute of Propulsion Technology is a co-operation partner of RRD and an innovator in the fields of combustion, turbines and acoustics. Further information: Research and University Technology Centres | Rolls-Royce