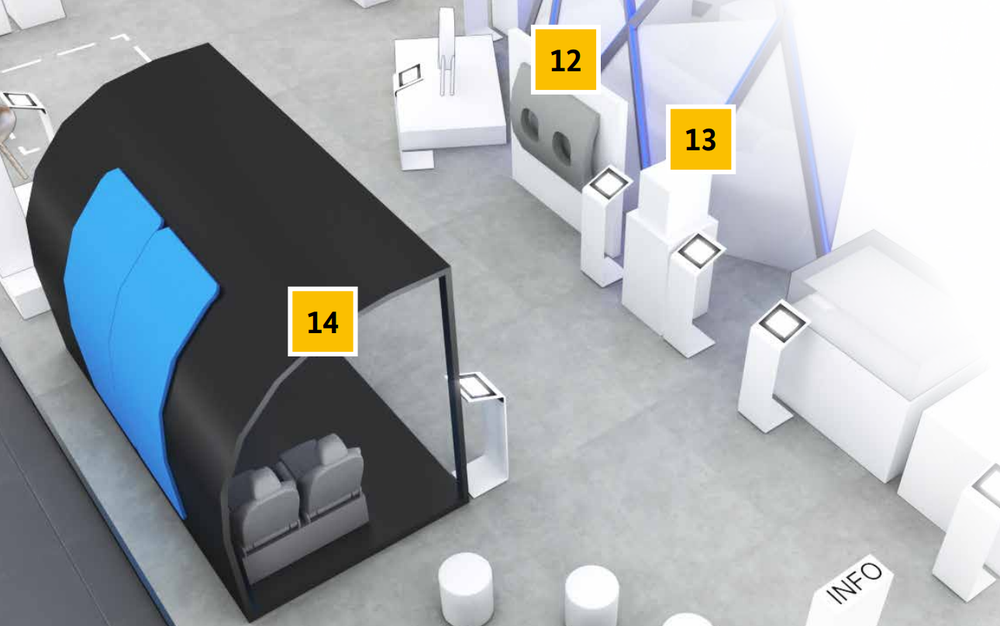

Cabin

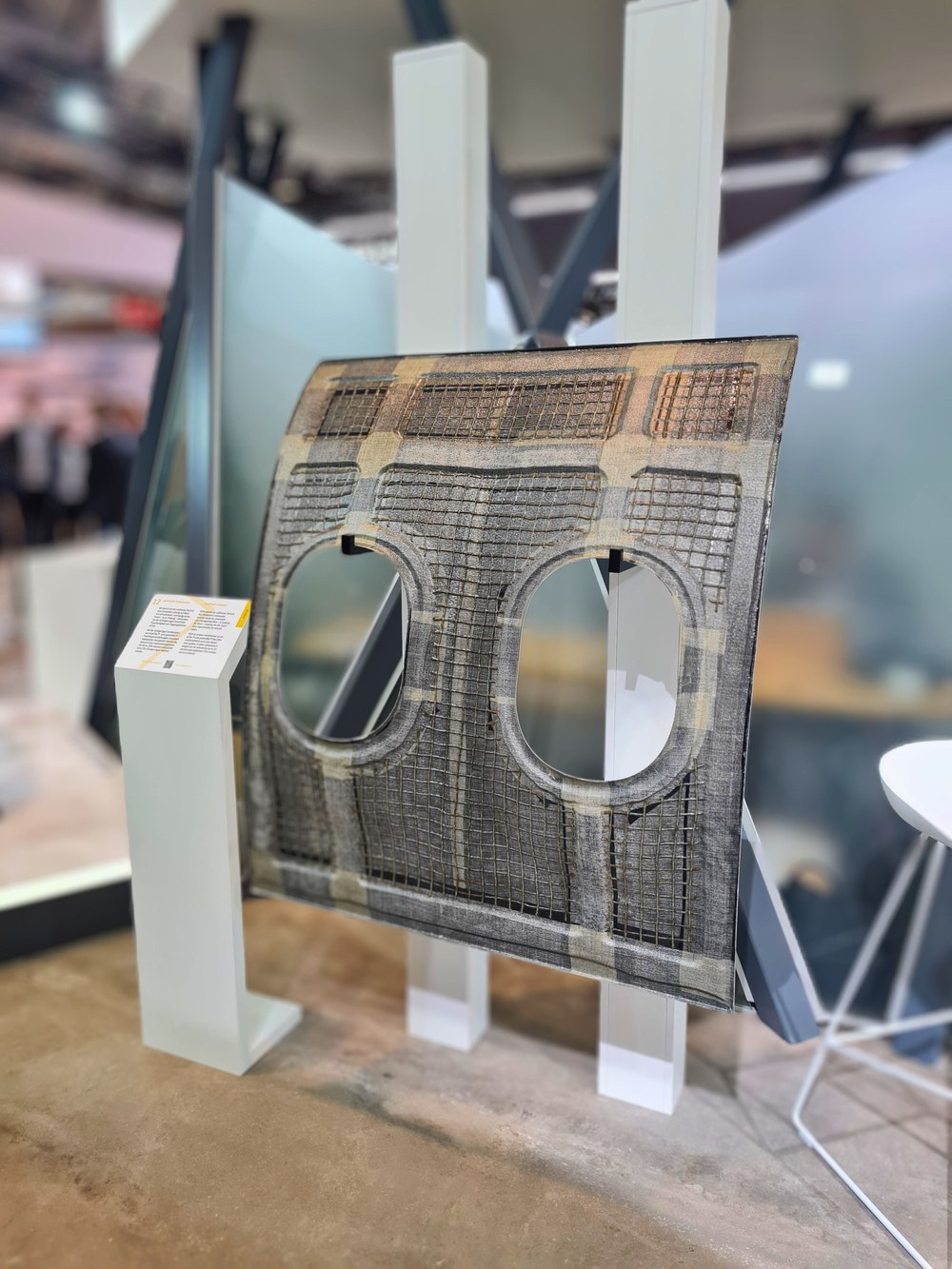

12: AeroFLAX side panel

Lufthansa Technik

Cabin interior made of renewable material: With AeroFLAX, Lufthansa Technik has developed the first airworthy composite solution based on renewable, eco-efficient and airworthy pre-impregnated fibres. Materials inspired by flora and fauna are also finding their way on board: Lufthansa Technik has developed a material combination based on flax fibres and a biological resin in collaboration with the Swiss company Bcomp, the leading provider of natural fibre reinforcements for everything from racing cars to spaceships. Flax, known as the original plant for linen fabrics, is the first "renewable and eco-efficient" fibre for use in aviation as AeroFLAX. Based on the unique combination of ampliTex™ and powerRibs™ flax fibre reinforcements with a bio-based resin system, it can be used to develop components that save up to 20% in weight compared to conventional glass fibre components. Less weight means less paraffin consumption and lower CO2 emissions. Theoretically, any part made of glass or carbon fibre can also be made of flax fibre.

Possible areas of application:

- Side wall panelling

- Ceiling panel

- Door frame panelling

- Toilet cover

Saves up to 20 % weight thanks to flax-optimised design. Improves the ecological footprint thanks to bio-based materials. Additional CO2 savings over the entire life cycle of the components.

Further information can be found at www.lufthansa-technik.com/en/aeroflax

Lufthansa Technik

Lufthansa Technik

The Lufthansa Technik Group is one of the world's leading providers of aeronautical services. More than 23,000 employees work for the internationally certified maintenance, manufacturing and development organisation at dozens of locations around the globe. Lufthansa Technik's portfolio covers the entire service spectrum for commercial, VIP and special mission aircraft.

13: FAIRcraft - Sustainable aircraft cabin of the future

With the FAIRcraft project, the companies Diehl Aviation, AUTOFLUG GmbH, CompriseTec and BFGF Design Studios are pursuing the idea of an aircraft cabin that is optimised in terms of sustainability. The major challenge is being met with a circular design in which all components are harmonised in such a way that they are durable, easily replaceable and recyclable and also have a low weight. One example of this radically new approach is a textile seat solution from AUTOFLUG, which can achieve a weight reduction of around 25%.

Further information can be found at https://www.autoflug.com/de/autoflug-airseat/

AUTOFLUG

Autoflug

For over 100 years, the name AUTOFLUG has been inextricably linked with the rescue and safety of people - on land, at sea and in the air. With our innovative proposals not only in the field of rescue and safety, but also for the flexible utilisation of aircraft cabins, we are well positioned for the future. Our customers are at the centre of our attention and can rely on our products and service at all times.

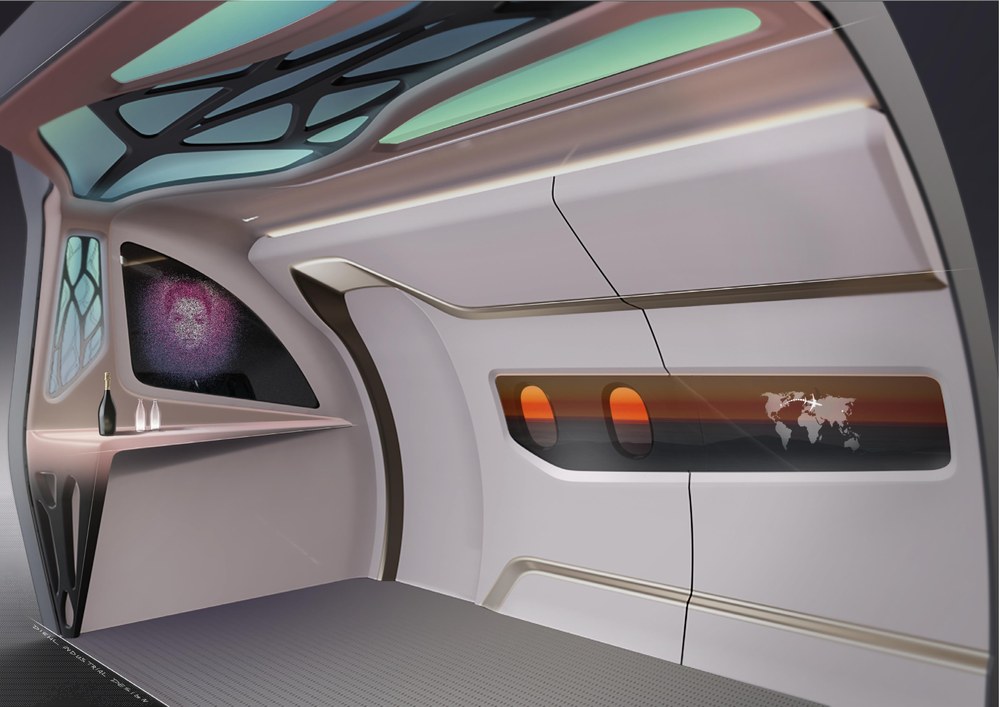

14: Future Cabin - a forward-looking vision

Diehl Aviation

With the Future Cabin, Diehl Aviation offers a glimpse into the future of the passenger cabin, emphasising that the aviation supplier is the best partner for realising the visionary wishes of its customers. The Future Cabin, which will be shown life-size, emphasises the commitment to sustainability: demonstrations will show how bionic structures on board contribute to weight reduction. The latest findings from materials research are incorporated into these highly efficient bionic structures. In addition, the concept emphasises the importance of a circular economy by incorporating considerations on the recyclability of materials from the outset.

The Future Cabin also offers other functions. The innovative integration of screens, projections and lighting functions enables seamless customisation while increasing passenger comfort. The concept also demonstrates the use of virtual exterior views for windowless areas on board. In addition, Diehl's Future Cabin demonstrates the possible integration of artificial intelligence through various scenarios. The concept is characterised by its extensive customisation options and comprehensive cabin design. Diehl Aviation's in-house industrial design department ensures that the entire cabin is tailored to individual customer requirements.

Further information can be found at https://microsite.diehl.com/aviation-highlights/en/

Diehl Aviation

Diehl Aviation

Diehl Aviation combines great innovative strength and solution-orientation for the mobility of the future. The company not only offers its customers state-of-the-art solutions for all service areas, but also meets current global challenges such as digital and networked functions, eco-efficient flight and faster installation requirements. Diehl Aviation is part of the Diehl Group, a globally active family-owned company.