Final Report (in German)

Energy diagnosis of buildings (Phase II)

The building with a floor space of 240 m² has been designed in low energy standard, in order to investigate the possibilities and limits to reduce energy demands for industrial buildings. The reason for this is that the material and energy flows may differ significantly from those which occur in living areas. Therefore, other approaches to reduce energy consumptions in buildings are required.

The building itself and the earth-to-air heat-exchanger were measured intensively five years in order of the Ministry of Research NRW. This was done as part of the "Arbeitsgemeinschaft Solar Nordrhein-Westfalen" in the project "Energetic diagnosis of buildings" in a network of 13 other buildings in North Rhine-Westphalia. The results of this project can be found on the website of the University of Siegen. As one result of the work, the "Planning Guidelines L-EWT" originated.

During planning and construction of the building, the following essential aspects were considered:

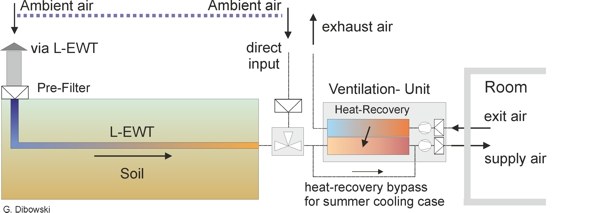

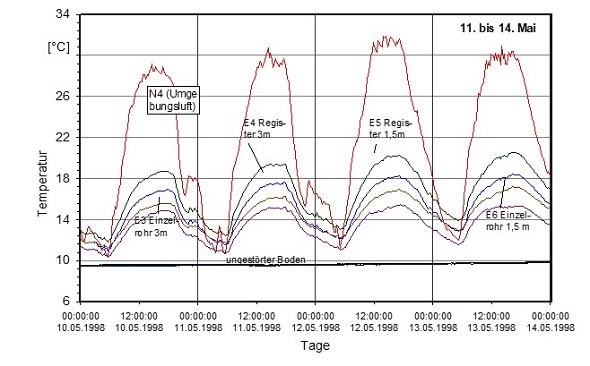

In addition to these passive measures the earth-to-air heat-exchanger (L-EWT) is the central element for active room air tempering. The L-EWT consists of horizontal laid in the ground pipes, passes through the outside air in the conventional ventilation system of the building. Depending on the season, the temperature difference between the ground and the outside air leads to a cooling or heating effect of the transported air and thus for the ventilation of the building. Due to a relatively small amount of electrical energy to drive the fan, heating and cooling costs can be saved. Hence a conventional air conditioning system is not required.

DLR Messwerte für AG Solar Nordrhein-Westfalen

Because of the high number of heat sources within the solar furnace building (people, computer, industrial installations, thermal processes), the room cooling by the L-EWT has a positive effect on the temperature in the building, especially in summer.

In the joint research project L-EWT a comprehensive planning guide has been developed under the leadership of the DLR, that covers all (analytic and numeric) system sizes and calculation methods. With a variety of nationwide measured test facilities a comprehensive set of rules for calculating L-EWT of all sizes is available now for free in the following download area.