Chemical and physical fundamentals

The department of chemical and physical fundamentals is working on alternative methods for the production of renewable energy carriers. One focus is on the utilisation of heat transfer media with high thermal stability for the transfer of thermal energy into chemical processes. Photoelectrochemical processes for material conversion are also being investigated. The main aim is to develop reliable materials and components for industrial use. To this end, innovative approaches are tested and evaluated, ranging from the laboratory to technical scale in our own large-scale facilities or in an industrial environment.

Materials, components and production processes for renewable energy carriers

The main task of the department is to develop and qualify materials, components and processes for the environmentally friendly production of renewable energy carriers.

The production of energy carriers by thermal synthesis requires robust media and equipment that can withstand the high temperatures and fluctuating operating conditions that can occur with solar or electric heating.

The growing requirements in terms of occupational safety and environmental compatibility also mean that tried-and-tested solutions need to be scrutinised and replaced by sustainable alternatives. This concerns the development of heat transfer media, reactor and apparatus technology for heat transfer medium-based production of energy carriers, treatment processes, construction materials and functional materials.

Qualification of heat transfer media and process technologies at high operating temperatures

One focus of the department is on the qualification of promising heat transfer media and innovative process technologies for operation at high temperatures as well as on improving the properties of these media. In addition, new processes, in particular for the production of energy carriers by means of chemical reactions (synthesis) and important chemical base materials, are investigated. We are focussing on organic and organosilicon heat transfer media and molten salts.

We carry out ageing tests on potential heat transfer fluids, evaluate quality changes and determine ageing kinetics based on the degradation of the starting materials and the formation of degradation products.

In addition, we analyse the relevant physico-chemical properties beyond the upper end of the advised operating temperature range and under application-relevant conditions with regard to temperature, pressure or dissolved gases. This enables us to avoid unreliable extrapolations that can occur when using simple standard tests.

We also analyse used media from heat transfer systems with regard to specific parameters such as the gases dissolved under operating conditions. In particular, we support the analysis and monitoring of dissolved hydrogen in heat transfer media from solar thermal parabolic trough power plants and the hydrogen content of used receiver elements from these plants worldwide.

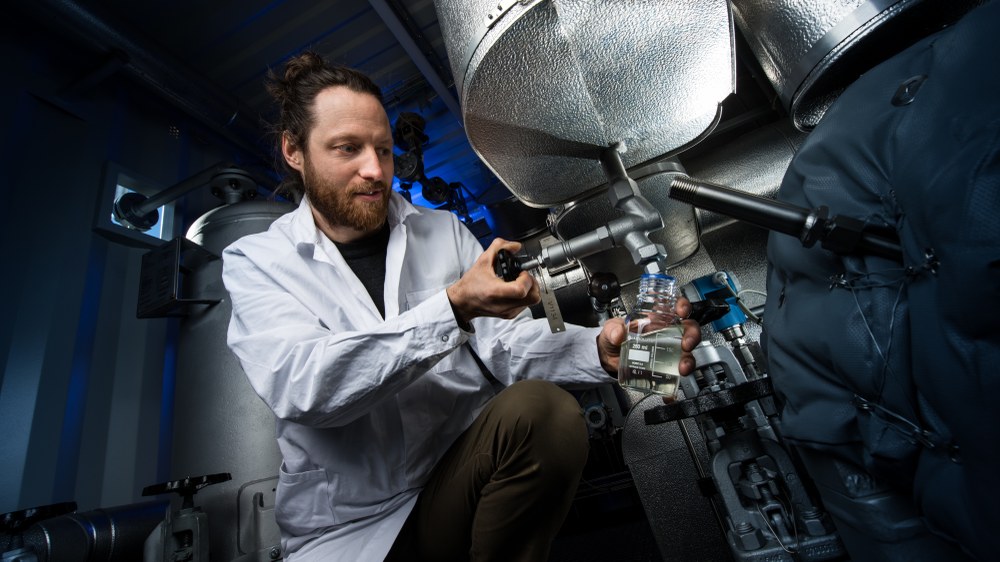

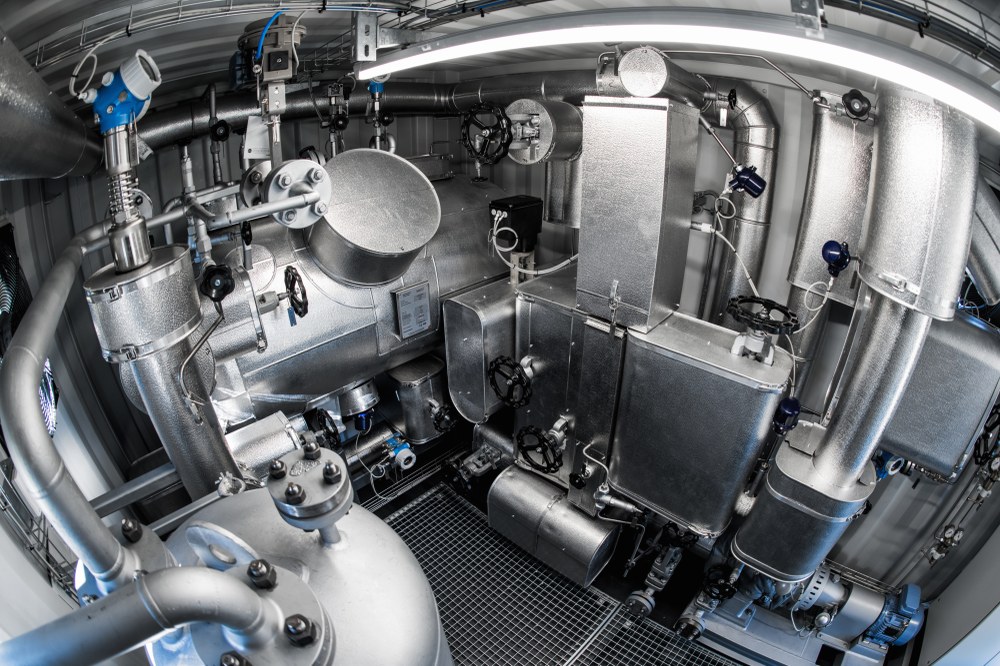

In addition, we analyse the interaction of heat transfer media with fluid technology components and qualify their properties if required. This includes, for example, investigations into the permeation and absorption capacity of hydrogen in receiver elements of solar thermal power plants, the qualification of sensors for the inline analysis of heat transfer media in comparison with reference methods, of flow measurement systems in heat transfer systems, electric heaters, pumps and other units.

For our research activities we have a heat transfer fluid laboratory and heat transfer systems on pilot plant scale like the mobile pump and heat exchanger test stand (MOPUW).

Photoelectrochemical and photocatalytic systems and processes

Another focus of the department is the development and qualification of photoelectrochemical and photocatalytic systems and processes, in particular for splitting hydrogen from water. We also investigate waste water as a raw material for hydrogen production.

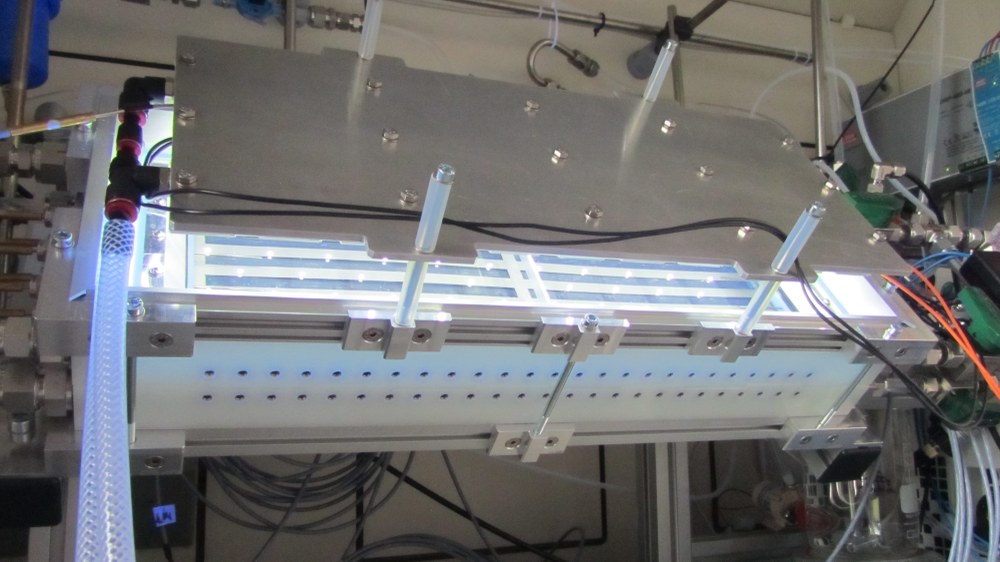

We are also evaluating alternative electrolysis processes in combination with concentrating solar technology. We determine the properties and stability of the components in laboratory and solar field tests. We also design possible new systems and determine the parameters required for process engineering evaluation.

For experimental work from laboratory to technical scale, we have access to laboratory analysis techniques, artificial light sources and electro-analytical testing facilities.

Our SoCRatus test stand enables detailed investigations with particularly homogeneously concentrated solar radiation under very controlled conditions with regard to spectral irradiation, media temperature and flow rate, as well as online analysis of the products.

For further scaling investigations, we have access to the Institute's large-scale facilities such as the High-Flux Solar Furnace, the Solar Simulator and the Synlight.

Catalytic processes for the thermochemical synthesis of energy carriers

The development of catalytic processes for the thermochemical synthesis of energy carriers is another focus of the department. For example, we are investigating suitable processes for the disproportionation of sulphur dioxide to sulphuric acid and sulphur as an energy carrier for storing solar energy.

We are investigating the possible applications of nanostructured catalysts for the synthesis of energy carriers such as methane, methanol or ammonia or for the development of hydrogen-degrading aggregates in order to avoid undesirable emissions in hydrogen applications.

Research from the laboratory to industrial application for a sustainable energy supply

With our work on new heat transfer media, we support the development of regenerative provision of heat and electricity and the short-term conversion of production processes to a renewable energy supply. Our research and testing facilities for media and components support the chemical industry, plant engineers and planners in the development of innovative products from laboratory scale through pilot plant tests and demonstration applications to market launch.