DLRmagazine 167 - Down to the very last detail

As aeronautics goes increasingly digital, how will simulations and experiments complement each other in the future?

Your consent to the storage of data ('cookies') is required for the playback of this video on Quickchannel.com. You can view and change your current data storage settings at any time under privacy.

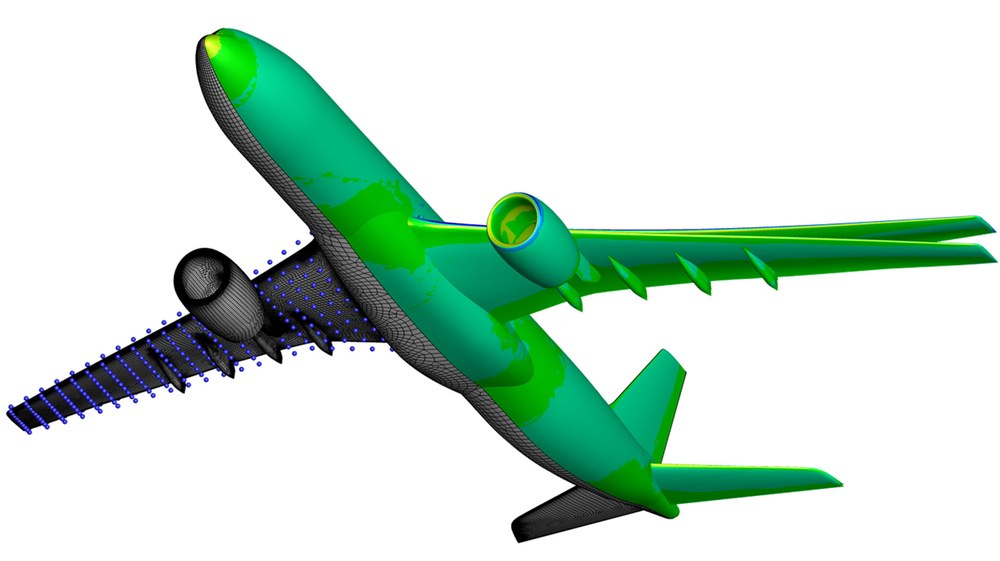

The wings flex, the fuel tank contents slosh, the loading of passengers and cargo varies from flight to flight – aircraft are highly complex systems influenced by numerous variables. What are the implications if some of them change? Or all of them? From now on, the answers are only a few mouse clicks away. Researchers at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) have developed a basis for the complete digital development and description of an aircraft in the Virtual Aircraft Technology Integration Platform (VicToria) project.

Thirteen DLR institutes with more than 160 researchers were involved in the VicToria project."We are now able to carry out virtual flight tests that can be matched in detail with real flight tests," explains Stefan Görtz, the VicToria Project Manager from the DLR Institute of Aerodynamics and Flow Technology in Braunschweig. "This means we can build a virtual model of an aircraft or helicopter with all its characteristics." These can be used, for example, to improve passenger comfort during gusts or flight manoeuvres. But it extends far beyond that – DLR can virtually design, test and fly aircraft that do not yet exist. This includes the possibility of evaluating new technologies to make flying more environmentally friendly and cost effective.

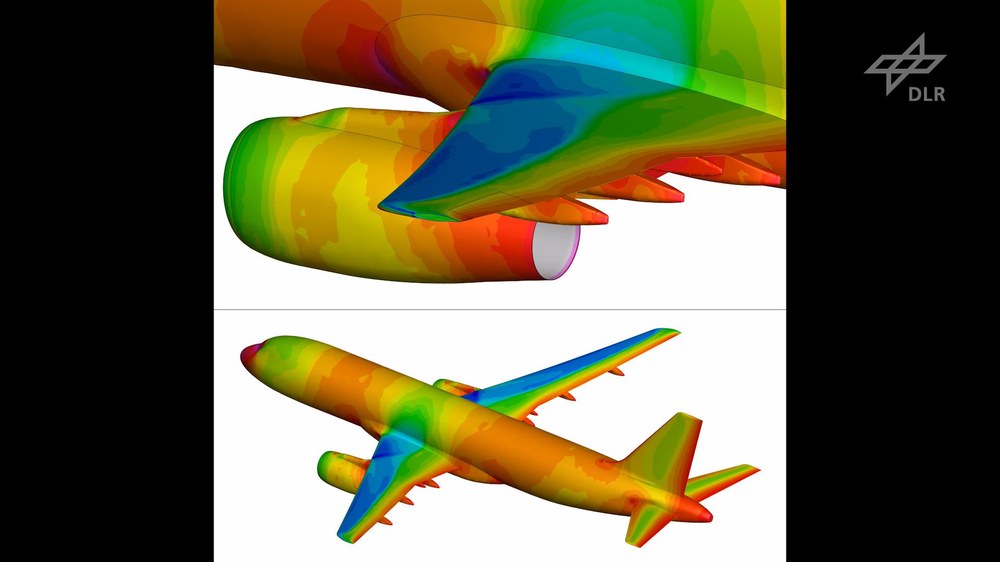

"We are making steady progress towards the digitalisation of aeronautics," says Görtz. DLR has brought together all the relevant disciplines – aerodynamics, aeroelasticity, load analysis, flight dynamics and structure – in the VicToria project, which has run for four years with an expenditure of 36 million euros. The virtual tests with a 'digital twin' of the DLR Advanced Technology Research Aircraft (ATRA) were verified using data from wind tunnel tests and actual flights. This allowed the simulation models to be constantly updated. For example, a stereo camera system measured the deformation of the wings during various flight manoeuvres.

The idea of designing a purely digital process for developing and certifying an aircraft was born almost 50 years ago. At the time, it was believed that real flight testing could soon be dispensed with; this was a mistake. Not only was the performance of computers limited at that time, but complex airflows, for example, could not yet be represented correctly. This is now possible with the help of

Future aircraft engineering - The numerical simulation

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

An in-depth interview with Stefan Görtz on the digitalisation of aeronautics was published in DLRmagazine 167.

DLR institutes and facilities involved

Institute of Aerodynamics and Flow Technology, Institute of Aeroelasticity, Institute of Propulsion Technology, Institute of Structures and Design, Institute of Composite Structures and Adaptive Systems,Institute of Flight Systems, Institute of System Architectures in Aeronautics, Institute of System Dynamics and Control, Institute for Software Technology, Flight Experiments Facility, Systemhaus Technik, Institute of Software Methods for Product Virtualization, German-Dutch Wind Tunnels.

The A320 ATRA

The Airbus A320 Advanced Technology Research Aircraft (ATRA) is the largest member of the DLR aircraft fleet. ATRA is unique because it is a combination of a commercial aircraft and a flexible research infrastructure component. In addition to an interface providing access to a wide range of aircraft parameters, almost any experiment-specific modifications can be carried out on the aircraft.