Hydrogen & Derivatives

To counteract man-made climate change, the transition to an economy that avoids CO2 emissions is essential. The basis of decarbonisation is the switch from fossil fuels to carbon-free and renewable energy sources. In some sectors, such as heavy industry, long-distance transport, shipping and aviation, this transition is particularly difficult; these sectors are known to be hard to convert. Hydrogen can play a crucial role in driving decarbonisation in these sectors, but only if it is produced with renewable energy, transported to the point of consumption and used efficiently.

Our research group is looking at the challenges and opportunities along this value chain for renewable hydrogen. The focus is on upstream integration, large-scale transport and the efficient utilisation or conversion of hydrogen into derivatives.

Fields of application

Our work focuses on optimising the overall system while improving and optimising the electrochemical conversion using advanced electrolyser technologies that provide system configurations that can reduce the cost and environmental impact of transition measures.

In the field of alkaline electrolysis, we aim to develop advanced alkaline electrolysis systems suitable for upstream and downstream integration. In this context, we focus on increasing pressure, enabling dynamic operation, understanding and mitigating degradation, especially during transient operation, and ensuring high hydrogen purity while maintaining safety. This is achieved by developing and optimising more advanced Balance of Plant (BOP) and advanced controls for AEL.

Similarly, our research on solid oxide electrolysis cells (SOEC) includes scaling up systems, increasing operating pressure, reducing degradation and improving dynamic performance.

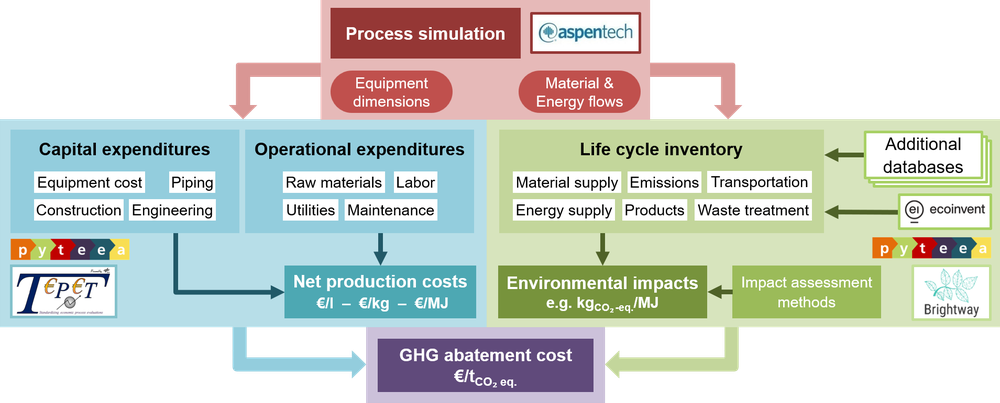

As part of our activities, we develop the methodology and carry out techno-economic and environmental assessments to optimise process chains and evaluate the feasibility and environmental impact of producing green hydrogen and derivatives. In this way, we ensure that our solutions are effective, scalable, sustainable and cost-efficient. By addressing these critical areas, we support the decarbonisation of hard-to-convert sectors.

Expertise

Experimental work on the alkaline low-temperature electrolysis system

In our research on the low-temperature alkaline electrolysis system, we focus on investigating atmospheric and pressurised systems, analysing reactor and system components, and evaluating system responses to an intermittent power supply. Our efforts are focussed on improving the system architectures and BOP as well as improving the control system to understand the system and module responses in different operating modes. Our goal is therefore to develop an advanced alkaline electrolyser system that can operate under both fluctuating and pressurised conditions and is suitable for integration into upstream and downstream processes for green hydrogen production under high pressure.

These activities are based on both experiments and modelling, including both steady-state and transient simulations. The same approach and considerations could also be applied to alkaline electrolysers operating at lower caustic concentrations, such as anion exchange membrane (AEM) electrolyser systems.

Infrastructures for low-temperature alkaline electrolysis systems

Our test facilities include customised in-house and externally acquired test rigs for alkaline electrolysers. Our facilities support tests from 1 to 50 kW under high pressure (up to 50 bar) and unpressurised conditions and temperatures up to 120°C.

Experimental investigations on SOC reactors

Atmospheric and pressurised investigation of SOC stacks (1-3 kW on the HORST pressure test bench) and reactor modules of several coupled SOC stacks (up to 150 kW on the GALACTICA test bench) in fuel cell and electrolysis operation, parameterisation and validation of CELESTE and TEMPEST models, investigation of stationary and transient operating strategies.

SOC-System-Experiments

Installation and operation of complex process chains (e-Xplore: pressurised SOEC system for direct coupling with downstream chemical synthesis processes; hybrid power plant: virtually coupled hybrid power plant with pressurised SOFC and gas turbine).

Framework for transient simulation TEMPEST

TEMPEST is used to investigate the steady-state and dynamic behaviour of process engineering systems with electrochemical reactors. The two main areas of application are the development of control and operating strategies and the investigation of scaling strategies. In both cases, the distribution of critical parameters within cells and reactors (temperature, current density, flow rate, gas composition) is analysed.

Specific applications of the simulation framework include, for example, the investigation of a hybrid system consisting of reactors with solid oxide fuel cells (SOFC) and batteries for a maritime powertrain and the direct integration of volatile renewable electricity into electrolysis processes. In both cases, the effects of fluctuating electrical power on the reactors and which control and operating strategies can be used to increase efficiency and service life are being investigated.

A strong synergy with experimental investigations is also being sought. On the SOC side, the HORST and GALACTICA test benches will provide important data for parameterisation and validation. On the alkaline electrolyser side, the Artemis and HERA test benches will provide a platform for the parameterisation and validation of prediction models developed for the system behaviour of alkaline electrolysers in transient operation. Subsequently, the simulation framework can provide operating characteristics that go beyond the experimental possibilities and support experimental investigations.

Conceptual design of large systems CELESTE

CELESTE is used to design and evaluate conceptual process designs in electrochemical process systems. The main area of application is therefore PtX systems, in which electrochemical reactors are used to produce hydrogen or synthesis gas, which then react in further processes to produce high-value chemicals. Such systems can be optimised by adjusting the operating conditions and integrating currents to achieve higher yields, lower thermal energy or power requirements, etc. CELESTE aims to simplify this process.

Due to the various forms of valuable streams in such systems, such as heat, chemicals and electricity, exergy analysis is an extremely useful tool to valorise the streams on an equal basis, as it compares the value of the stream with the "dead state" given by the environment. With CELESTE, users can quickly perform exergy analyses to evaluate such process systems holistically.

The conceptual process design serves as a preliminary study for the design of our experiments and transient simulations. Here, CELESTE provides an important interface for the synergetic interaction between our different research pillars. The experiments performed on our unique test facilities HORST and GALACTICA provide useful data for the validation of our models, and the simulations on CELESTE provide important information for the design of the experiments and transient simulations on TEMPEST. This is further enhanced by the ability to quickly perform optimisation studies to find the best parameters for operation.

Techno-economic and ecological process evaluation tool TEPET

TEPET enables detailed automated process evaluation from a technical (efficiency), economic (production, investment and operating costs) and environmental (life cycle assessment including global warming potential, water consumption, land use, etc.) perspective. Research focuses in particular on the investigation of processes for the production of alternative fuels (e.g. Fischer-Tropsch fuel, methane, ammonia, methanol, ...) from electricity and/or biomass. The aim of the research projects is both process analysis (e.g. identification and quantification of cost and environmental effects) and process optimisation (e.g. increased efficiency through heat integration and optimised operating conditions of the process units). The details of the TEPET tool include

- Automated pinch analysis and heat integration

- Automated determination of manufacturing costs based on an internal database Automated quantification of environmental impact using Brightway2 based on internal and commercial (ecoinvent) databases

- Automated sensitivity analysis

- Variance-based global sensitivity analysis on the basis of Sobol indices

- Analysing uncertainty