TEPET

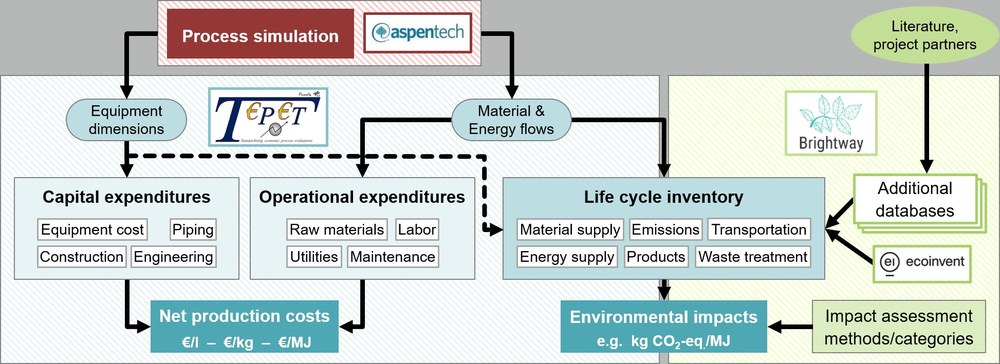

The Techno Economic Process Evaluation Tool (TEPET), developed at the Institute of Engineering Thermodynamics by the group Techno-Economic Analysis (TEA), enables an automated technical, economic as well as ecological process analyses. For this purpose, the processes are simulated in Aspen Plus®. The resulting material and energy flows and information on the process units are extracted from the process simulation. Automated sensitivity analyses can be realised by changing parameter/variables in the simulation through TEPET. As a result, this allows to automatically calculate for example the capital and operational expenditures, the net production cost and environmental impacts like the global warming potential.

Research goals

https://doi.org/10.1016/j.enconman.2021.114651TEPET allows to investigate processes from a technical (material and energy efficiencies), economic (net production cost, capital investment and operational cost) and ecological (e.g. global warming potential) perspective. A particular research focus is on processes for the production of alternative fuels (Fischer-Tropsch fuel, methane, methanol, ammonia, …) from electricity and/or biomass. Therein, the work targets to conduct in-depth process analyses (e.g. to identify and quantify cost and environmental impact drivers) as well as to improve the processes (e.g. efficiency increase through heat integration or optimal operating conditions of certain process units).

Simulation Framework Details

- Automated calculation of the net production cost on the basis of an internal database

- Automated life cycle assessment to quantify environmental impacts using Brightway 2 on the basis of internal and commercial (ecoinvent) databases

- Uncertainty analysis

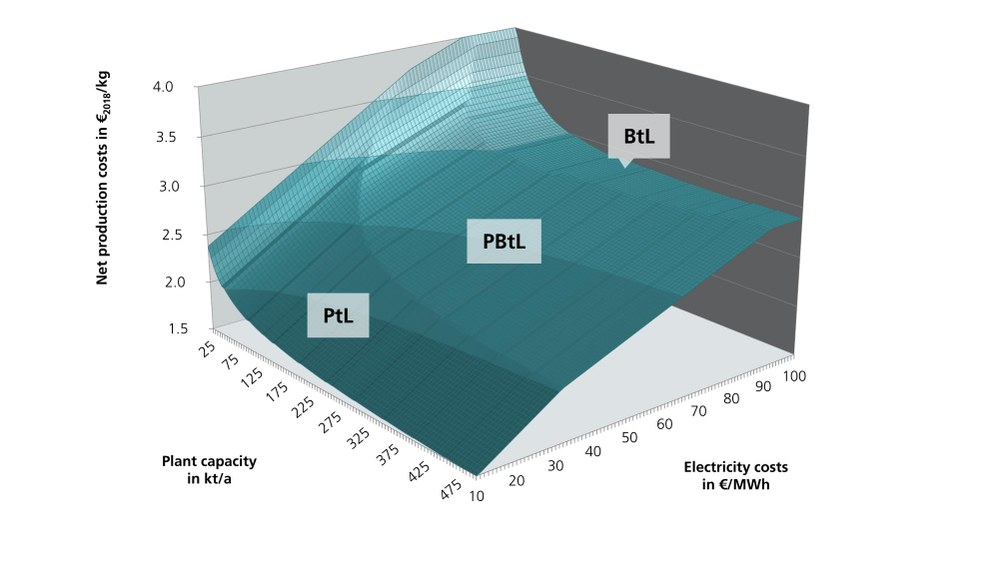

Exemplary result

Projects

Publications

- S. Adelung, Global sensitivity and uncertainty analysis of a Fischer-Tropsch based Power-to-Liquid process, Journal of CO2 Utilization, 65 (2022).

- S. Adelung, R.-U. Dietrich, Impact of the reverse water-gas shift operating conditions on the Power-to-Liquid fuel production cost, Fuel, 317 (2022).

- M. Raab, R. Körner, R.-U. Dietrich, Techno-economic assessment of renewable hydrogen production and the influence of grid participation, International Journal of Hydrogen Energy, 47 (2022) 26798-26811.

- F. Habermeyer, E. Kurkela, S. Maier, R.-U. Dietrich, Techno-Economic Analysis of a Flexible Process Concept for the Production of Transport Fuels and Heat from Biomass and Renewable Electricity, Frontiers in Energy Research, 9 (2021).

- P. Silva Ortiz, S. Maier, R.-U. Dietrich, A. Pinto Mariano, R. Maciel Filho, J. Posada, Comparative Techno-Economic and Exergetic Analysis of Circulating and Dual Bed Biomass Gasification Systems, Frontiers in Chemical Engineering, 3 (2021).

- S. Maier, S. Tuomi, J. Kihlman, E. Kurkela, R.-U. Dietrich, Techno-economically-driven identification of ideal plant configurations for a new biomass-to-liquid process – A case study for Central-Europe, Energy Conversion and Management, 247 (2021).

- M. Raab, S. Maier, R.-U. Dietrich, Comparative techno-economic assessment of a large-scale hydrogen transport via liquid transport media, International Journal of Hydrogen Energy, 46 (2021) 11956-11968.

- S. Adelung, S. Maier, R.-U. Dietrich, Impact of the reverse water-gas shift operating conditions on the Power-to-Liquid process efficiency, Sustainable Energy Technologies and Assessments, 43 (2021).

- Ralph-Uwe Dietrich, Friedemann G. Albrecht, Simon Maier, Daniel H. König, Stefan Estelmann, Sandra Adelung, Zoé Bealu, Antje Seitz, Cost calculations for three different approaches of biofuel production using biomass, electricity and CO2, (2017).

- F.G. Albrecht, D.H. König, N. Baucks, R.-U. Dietrich, A standardized methodology for the techno-economic evaluation of alternative fuels – A case study, Fuel, 194 (2017) 511-526.