HORST

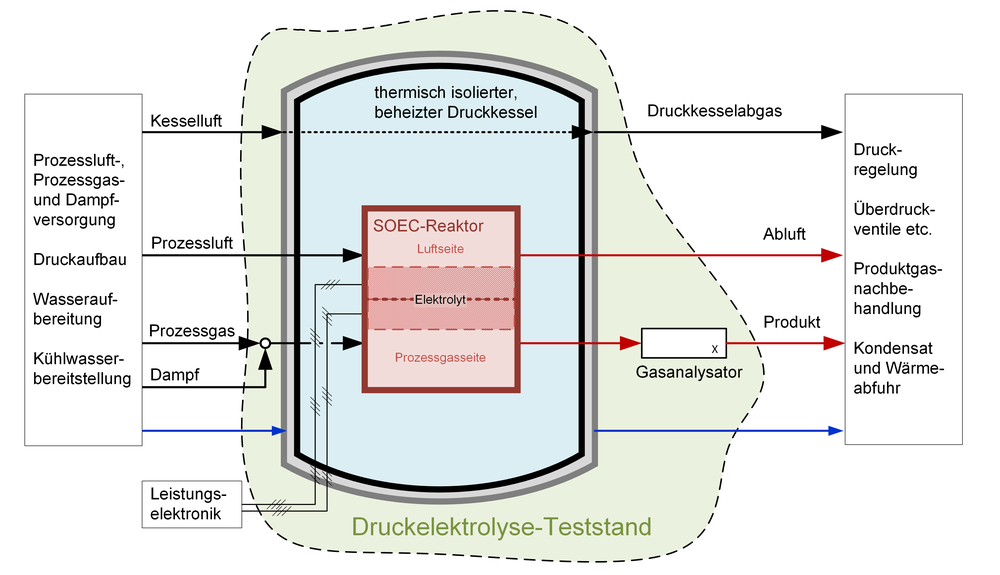

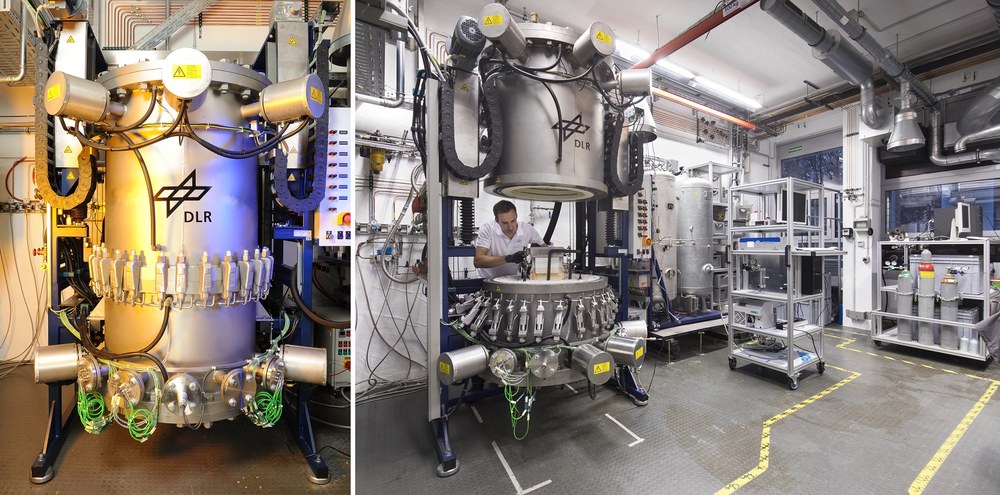

The HORST test environment at DLR's Institute of Engineering Thermodynamics in Stuttgart enables the investigation of solid oxide cell stacks (SOC) in pressurised electrolysis and fuel cell operation. With HORST, the institute has the rare opportunity worldwide to investigate SOC stacks in the pressure range between 1.4 bar and 8 bar and temperatures of up to 850 °C.

Research tasks

The research activities on small SOC reactors are aimed at the stationary and transient investigation of high-temperature fuel cells (SOFC) and electrolysers (SOE) under pressurised operating conditions.

With the help of HORST, the kinetic, electrochemical and thermodynamic behaviour of a SOC stack can be investigated in both operating modes and with varying process gas compositions. The identification and quantification of cell and reactor resistances at stack level is also a subject of investigation. The compact design of the tested SOC stacks and the resulting almost homogeneous gas distribution open up the possibility of using the test data to parameterise the cell and stack modelling of our group's TEMPEST and CELESTE simulation environments EHT to utilise. Pressurisation allows operating conditions of the SOC to be tested that lead to significant increases in efficiency in a system context with downstream processes.

Mode of operation

Various operating modes can be analysed:

Fuel cell mode (SOFC) for the generation of electricity up to 0.5 kWel

Electrolysis mode (SOE) for the production of hydrogen or synthesis gas (hydrogen and carbon monoxide) using electric current of up to 2 kWel

Reversible operation (rSOC) e.g. for the storage of electrical energy, for which SOFC and SOE operation are alternated

Media supply & disposal

On the fuel gas side, H2, CO2, CO, N2 and CH4 as well as H2O(g) (up to 10 g/min) are available. A pulsation-free supply of up to 100 % H2O(g) enables the experimental investigation of a wide range of gas mixtures. Co-electrolysis mixtures (H2O+CO2) can be set with very high accuracy between pure water and carbon dioxide electrolysis. On the air side, synthetic mixtures of N2, O2 and CO2 as well as dried air can be dosed.