e-XPlore

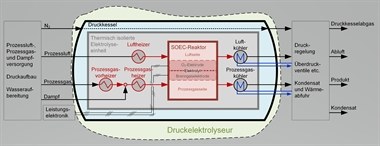

The transportable e-XPlore research platform currently being developed by the "Electrochemical High Temperature Processes (EHT)" working group at the DLR Institute of Technical Thermodynamics in Stuttgart will enable the investigation of SOC reactors with several SOC stacks in pressurised electrolysis and fuel cell operation. Operating pressures between 8 bar and 50 bar can be set.

Research tasks

The aim is to test and characterise the electrochemical SOC reactors in high-pressure operation in order to develop operating strategies and enable low degradation rates and high power and energy densities. The focus is on investigations in electrolysis mode. The hydrogen produced during the electrolysis of water or the synthesis gas produced from carbon monoxide and hydrogen during the simultaneous electrolysis of water and carbon dioxide (co-electrolysis) can then be further processed in various chemical processes. One example is the Fischer-Tropsch synthesis, which is carried out at approx. 25 bar. The high outlet pressures of the gases produced in high-pressure electrolysis make it possible to efficiently supply the coupled processes with educts without additional intermediate steps. By coupling the processes, electrical energy can be converted with high efficiency into easily storable liquid or gaseous chemicals with high energy density.

The construction of the test environment will be self-financed by DLR with almost €3.7 million and will be realised in Project H2Mare: PtX-Wind coupled with a transportable synthesis of the project partner KIT-IMVT.

Mode of operation

Various operating modes can be analysed:

- Electrolysis mode (SOE) for the production of hydrogen or synthesis gas from hydrogen and carbon monoxide using electrical energy of up to 10 kWel

- Fuel cell mode (SOFC) for power generation up to 3 kWel

- Reversible operation (rSOC) e.g. for the intermediate storage of electrical energy, switching between SOFC and SOE operation.

Media supply and disposal

On the fuel gas side, H2, CO2, CO, N2 and CH4 are available. The gas mixture is compressed to operating pressure, preheated and mixed with already compressed water vapour (up to 7.5 kg/h). The gas mixture is then heated to operating temperature. Up to 20 m³/h of filtered ambient air is used for the air supply. The gases are compressed using different compressors and metered using MFCs. The gases are heated to an operating temperature of up to 850 °C by several heaters with a total electrical output of 15 kW. Buffer tanks and differential pressure regulators are installed to prevent pressure fluctuations. The thermal energy of the products is not recuperated by heat exchangers in order to maximise flexibility for operation and the simulation of system operating states.

Extended examination options

In-situ characterisation methods such as online gas analysis of the product gases and electrochemical impedance spectroscopy (EIS) will provide a detailed view of the system performance as well as the identification and quantification of cell and reactor resistances at stack level.

Projects