AICloud: Development of an AI-based Virtual Sensor using a Cloud Computing Platform

Virtual Sensor on AFM

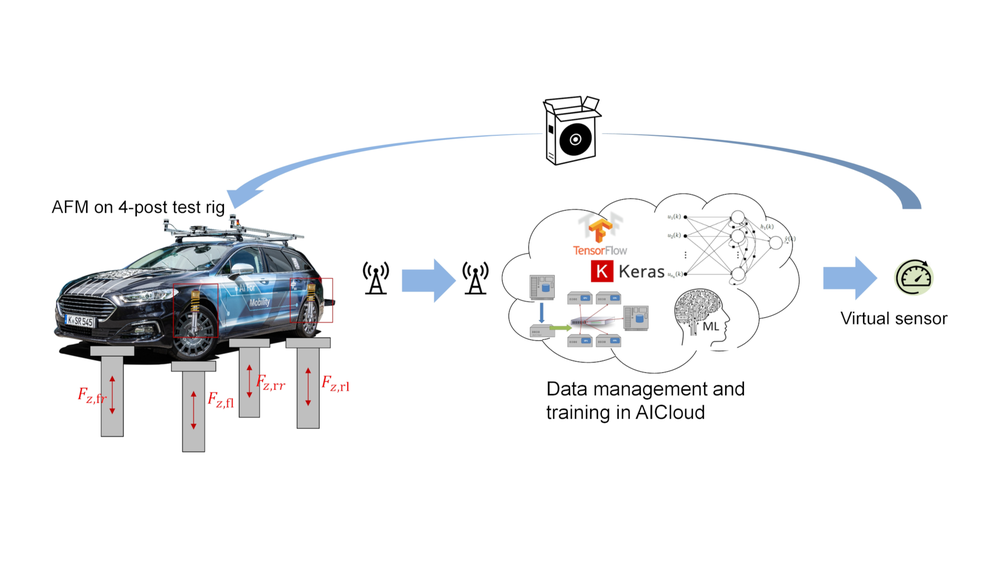

The research vehicle AI-For-Mobility (AFM) of the DLR serves as a test platform. The wheel vertical force, i.e. the force between a tire and a contact patch, is selected as the quantity to be estimated by the virtual sensor. The knowledge of this force is essential for vehicle dynamics control systems for both manual and automated driving. This physical quantity cannot be measured by a real sensor with reasonable effort. Its estimation is a challenging task tackled here by means of a trained recurrent neural network (RNN). The final trained RNN network can be then uploaded back to the AFM where it can be used as a virtual sensor to estimate the wheel vertical force.

To generate training data, the AFM is gauged on a so-called four-post-test-rig. Here, the vehicle is placed on four hydraulically driven posts, each of which is controlled to follow predefined position signals. Thus, the posts under the four wheels stimulate the vertical movement of the vehicle. In this way, driving on precisely defined road profiles can be simulated in a reproducible manner, with the dynamic wheel loads being measured by load cell sensors.

RNN Training

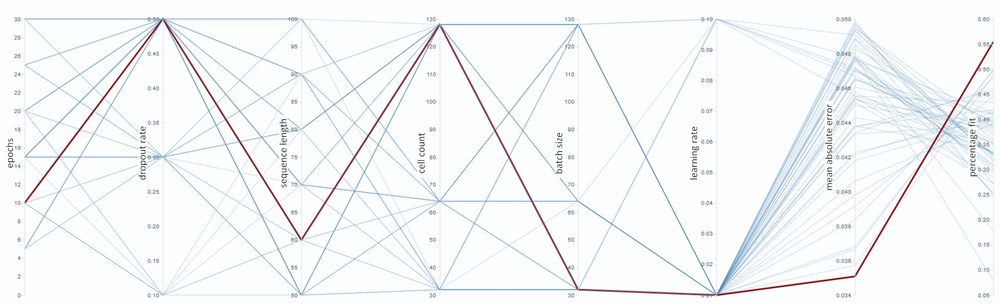

For the implementation of the recurrent neural networks, the widely used TensorFlow framework with its Keras library is used. It is an open-source deep learning library in the Python programming language. With Keras, it is possible to implement most of the currently used deep learning architectures. The RNNs used for the virtual wheel load sensor as well as their Long Short-Term Memory (LSTM) and Gated Recurrent Units (GRU) architectures are implemented in Keras. A RNN has numerous degrees of freedom or hyperparameters that specify the model and must be considered in the design process. These include, but are not limited to, the following parameters (compare figure below):

- Learning rate

- Maximum number of training epochs

- Number of cells

- Training sequence length

- Batch size

- Dropout rate

RNN training must be performed for each hyperparameter set to subsequently evaluate the performance of the respective model. Due to the rapidly increasing computational capacities required for this, hyperparameter optimization is efficiently performed in a high-performance cloud environment. The AICloud platform presented in more detail below is used for this purpose. The following figure shows the interactive OpenSearch dashboards visualization of the grid search results over the hyperparameter space of the RNN trainings. Each line represents a training configuration of the grid with associated validation metric (the mean absolute error, and the percentage fit). The best configuration is highlighted in red.

Results

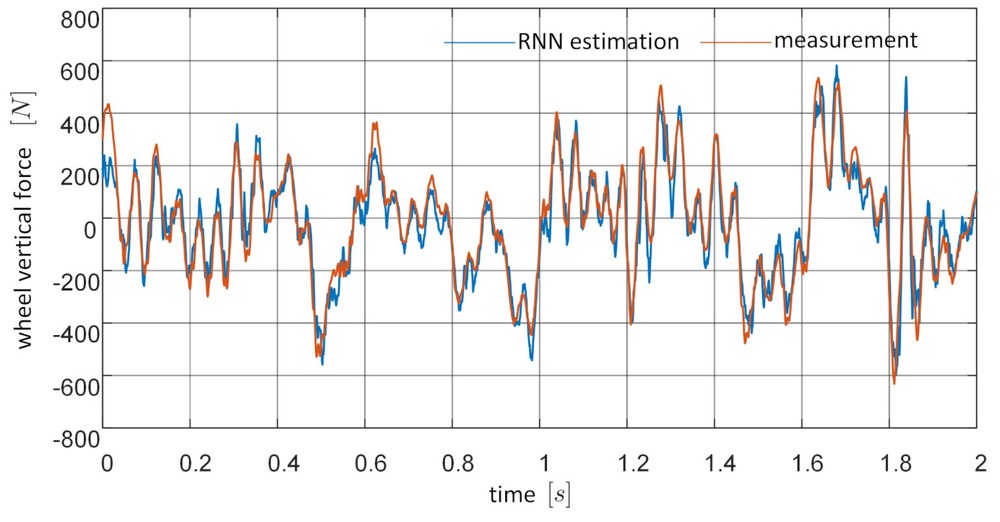

The RNN architecture determined from the hyperparameter optimization can be used to obtain good estimation results for the entire test data set. The following figure shows an example of the comparison between the estimated value of the learned virtual sensor and the true wheel vertical force measured on the four-post-test-rig. Obviously, the highly dynamic wheel load can be estimated very well and without a significant phase delay.

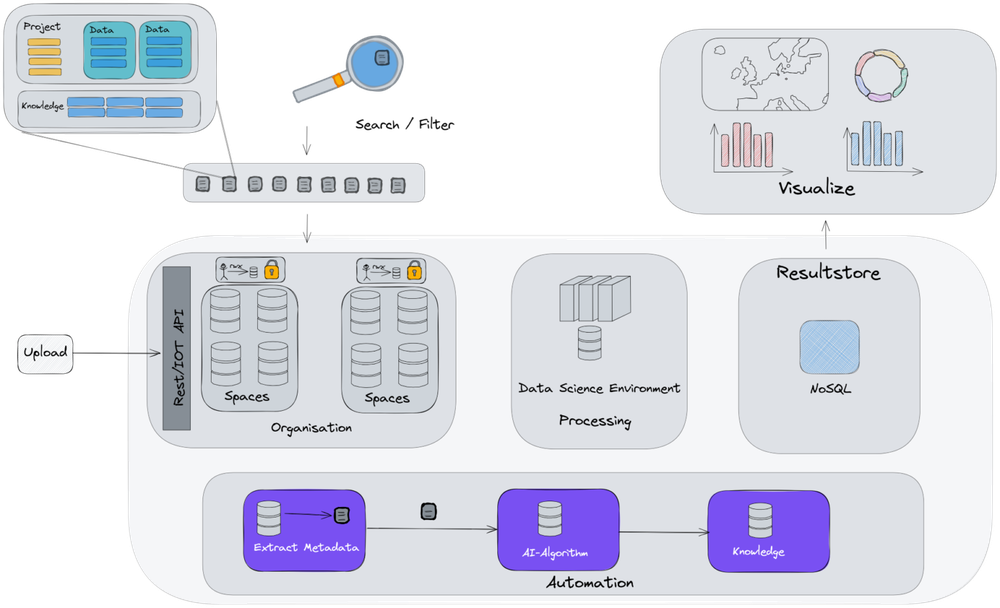

The management and analysis of the large amount of data measured by the AFM provides certain general challenges. To address these challenges, of how data can be

- uploaded and stored

- searched

- processed and analyzed

- visualized

- collaborated on

- kept in a legally compliant way

we developed a general-purpose, cloud-based data management platform where training and evaluation of the virtual wheel load sensor take place. The data is stored in the cloud together with a metadata enabling easy searchability and assignability for the user.

The Data Management Platform

In the course of this project, the Superb Data Kraken (aka SDK), a generalized, multi-functional data management platform has been designed and developed using existing open-source solutions where applicable and custom-tailored solutions otherwise. It offers a versatile and rich set of tools to easily handle the most common tasks encountered in data management. It provides all necessary functionalities including data and metadata storage, data processing, search capabilities over sensor data, metadata and training data plus a data science environment and visualization tools for test-, training- and meta-data. Throughout the entire platform, user permission management and separation of data between different use cases is ensured.

The core components of the project have been published under the Apache 2.0 License and can be found on GitHub.

To date, several use cases and projects already use the versatile SDK platform on a daily bases, from industry sectors over automotive, traffic to advertisement. Among those, the AICloud project constitutes an important showcase, as it combines big data with machine learning. In this context,

- a metadata model was developed that standardizes descriptive metadata input to allow precise search, data retrieval and visualization for the sensor data recorded with the AFM vehicle;

- a workflow was set up to enrich the metadata with analysis results from the data;

- training of the virtual sensor with hyperparameter tuning was performed within the platform’s data science environment leveraging cloud computing resources for significant speedup;

- the virtual sensor was subsequently deployed to the cloud and its predictions were validated against the measurement of the wheel load.

This work was funded by the Bavarian Ministry of Economic Affairs, Regional Development and Energy (StMWi, project AlCloud: Datenmanagementsystem am Beispiel virtueller Sensoren, grant number DlK0150/02).