Department Testing and Measurement Techniques

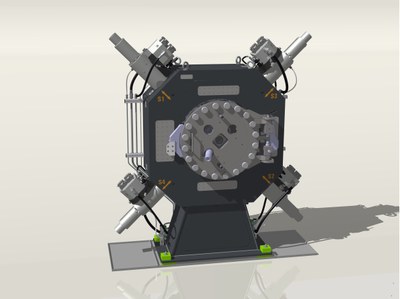

The Test Operation and Measuring Methods department is involved in carrying out experiments on innovative testing machines as well as the numerical mapping of the tests. The testing machines are able to test samples and real components under pressure and mechanical, thermal and corrosive loads. At the same time, all experiments are mapped in a digital twin in order to simulate and validate the material behavior during the tests. Further insights are gained from the metallographic examination of the samples.

The TMV department offers a unique test bench infrastructure with which the interactions of these service life-limiting influences can be investigated and quantified. The TMV department has two main areas of research - the investigation of hot gas-carrying components and materials in MTC test benches and the investigation of the secondary air system for cooling air supply in rotor test benches. In both research areas, the development of special measurement techniques is a particular focus in order to make the behavior of materials and components measurable under extreme operating conditions.

The results of investigations on these test benches are incorporated into the development of future generations of aircraft engines and gas turbines and thus into the upgrading of more efficient and, above all, more environmentally friendly machines. Testing and modelling are carried out in parallel and closely interlinked on the basis of end-to-end digitalization of all processes and resources, so that the models are validated with the help of a digital twin of the test bench configuration. This provides both a more detailed insight into the physical phenomena and allows conclusions to be drawn about meaningful changes to the test parameters.

It is important for the validation between simulation and experiment that the end-to-end digitalization of all processes and resources forms an overarching link between calculation and experiment.