Institute of Vehicle Concepts

The Institute of Vehicle Concepts is a system-oriented institute, handling and coordinating research subjects related to traffic and transportation at the DLR location in Stuttgart.

Duration: January 2022 to December 2025

The global challenges of transport in terms of climate change, securing mobility and managing the transition to a sustainable transport system are complex. The ProCo project represents a holistic and integrated approach that aims to enable climate-friendly, resource-efficient and sustainable rail transport.

The ProCo Propulsion and Coupling project is based on the four pillars of energy, efficiency, economy and ecology.

The replacement of diesel trains for environmental reasons and the recommissioning of closed lines have raised the question of which hybrid drive concept is best suited for each individual non-electrified railway line. Battery and/or hydrogen trains enable the transition to environment-friendly energy sources. Energy storage is the key to train concepts with hybrid drives. New intelligent solutions for hybrid energy supply concepts need to be investigated in order to optimise overall performance end-to-end. The aim is to develop and demonstrate a scalable, modular system kit for hybrid drive systems with standardised interfaces.

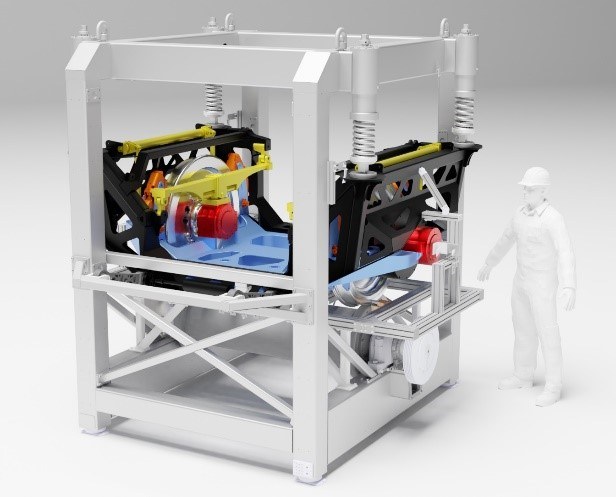

Advanced technologies such as low-loss traction must be thoroughly explored and integrated into railway applications, with the NGT train family serving as leading concepts and demonstrators. Accompanied by an extensive investment project, the full-size single-wheel bogie will be built and tested both on a rolling test rig and on track systems in order to advance and demonstrate the technological maturity of the incorporated technologies.

Railway operators must prioritise cost-effective operation. To achieve this, they should focus on optimising and automating operational processes, such as virtual coupling, as well as reducing energy consumption and minimising wear and maintenance expenses. This requires a systematic approach to organising technical design and deploying appropriate technologies for future rail vehicle drives. To enable this, utilising intelligent methods and tools to assess Life Cycle Costs (LCC) and monitor their development is essential.

Reducing emissions and the carbon footprint in the mobility sector, particularly in rail transport, is a challenging task and plays an important role in increasing the acceptance of new technologies in society. The integrated consideration of energy supply and drive components and driving modes/manoeuvres will consistently reduce the environmental impact. Furthermore, the replacement of diesel traction is being advanced, which is an important lever for reducing the CO2 footprint. The aim is to develop and optimise operating strategies and suitable tools to reduce energy requirements and emissions.

The ProCo project essentially focuses on the development of vehicle-side technologies. Key areas include:

The NGT single-wheel bogie is a new type of lightweight bogie featuring mechatronic track guidance and direct drive close to the wheels, which has been optimised for use in the NGT centre coach, particularly in terms of installation space. The objectives of the NGT chassis development encompass:

The intended result of the TP1000 is the world's first mechatronic lightweight single-wheel chassis with direct drive close to the wheel in TRL 6.

The subproject 2000 Virtually Coupled Train Sets (VCTS) builds upon the progress made in NGT BIT and the Shift2Rail project X2RAIL-3, focusing on the development and demonstration of a virtual coupling for rail vehicles. As part of the European Shift2Rail initiative, DLR has already carried out important work on VCTS concept development and analyses of feasibility and performance, positioning itself strongly not only nationally but also within the European context. Automation and digitalisation are pivotal in enhancing the efficiency and responsiveness of railways amidst increasing demands. Enabling individual trains to achieve virtual coupling during their journey enhances track throughput significantly by allowing multi-unit trains to join and separate virtually. The system's performance must undergo comprehensive analysis, considering both train-to-train and train-to-infrastructure interferences and interactions across various functional domains such as communication, electronics/electrics, mechanics, aerodynamics and train control. The primary objective of TP2000 is to prepare for the realisation of a VCTS demonstration by 2027.

Another crucial aspect involves achieving precise and dependable self-localisation of vehicles, particularly in routes featuring tunnels, with the assistance of magnetic field sensors. Preliminary findings regarding accuracy, reliability and potential interferences are being gleaned through the analysis of data collected from an extensive measurement campaign utilising the Deutsche Bahn's advanced TrainLab.

Video : Future technologies for rail transport – measurement campaign in the laboratory train, March 2021 (engl.)

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

DLR

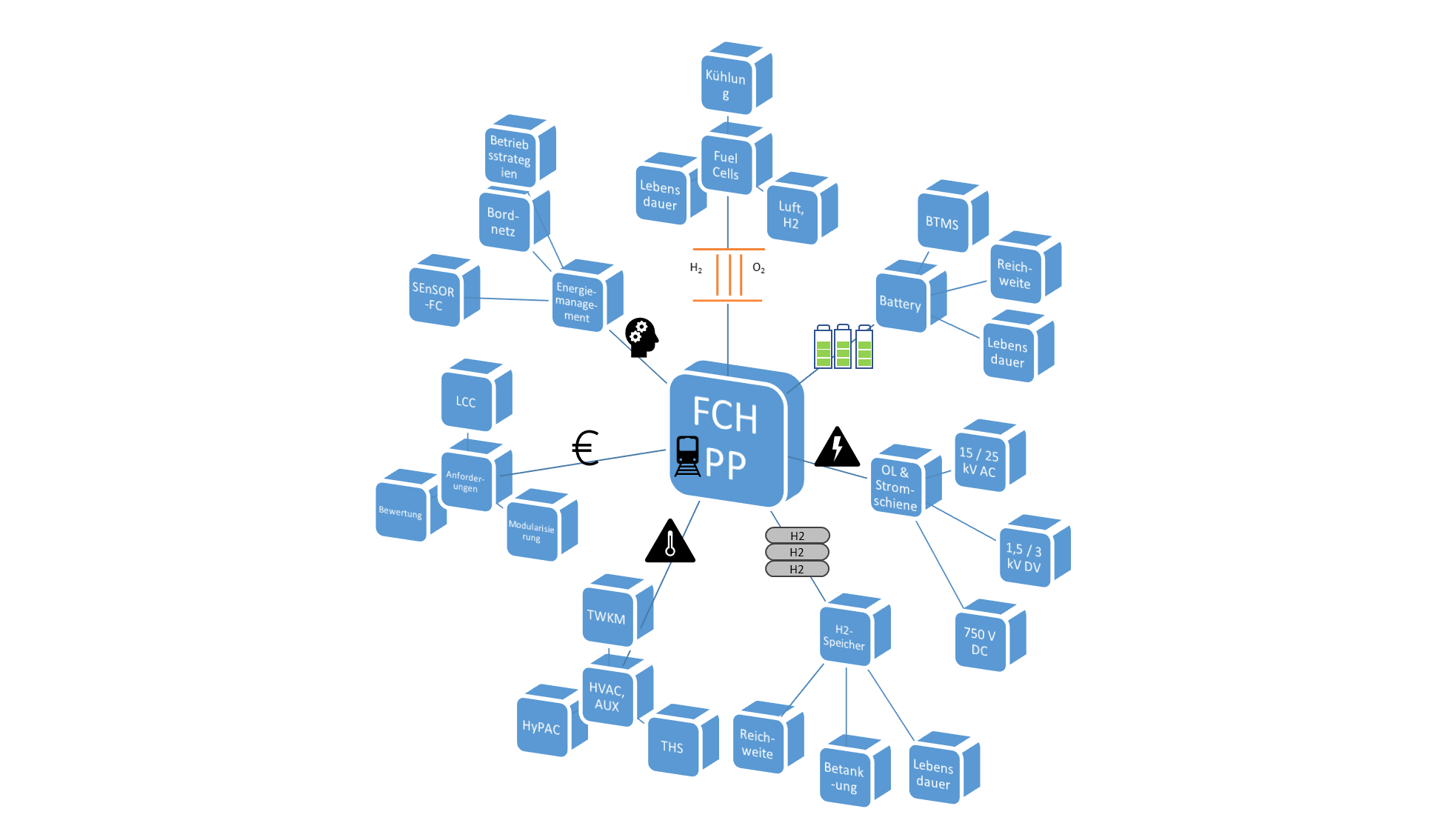

In the subproject 3000 Fuel Cell and Hybrid Power Pack (FCHPP), a modular and scalable system kit for alternative rail vehicle drives is being developed and demonstrated. The aim of the FCHPP concept is to support the decarbonisation of the railways by offering alternatives to the diesel drives currently in use. FCHPP uses basic building blocks to provide energy supply systems and architectures for rail vehicles that fulfill the necessary criteria, using scalable subsystems as modules with specified interfaces. The aim of ProCo TP 3000 (FCHPP) is to develop a system for designing a modular and scalable FC and battery hybrid power pack (FCHPP) that aligns with the established requirements. The project encompasses a wide spectrum of tasks, spanning from the development of methods, concepts, and technologies to design and demonstration, followed by energy distribution and cost optimisation (LCC).

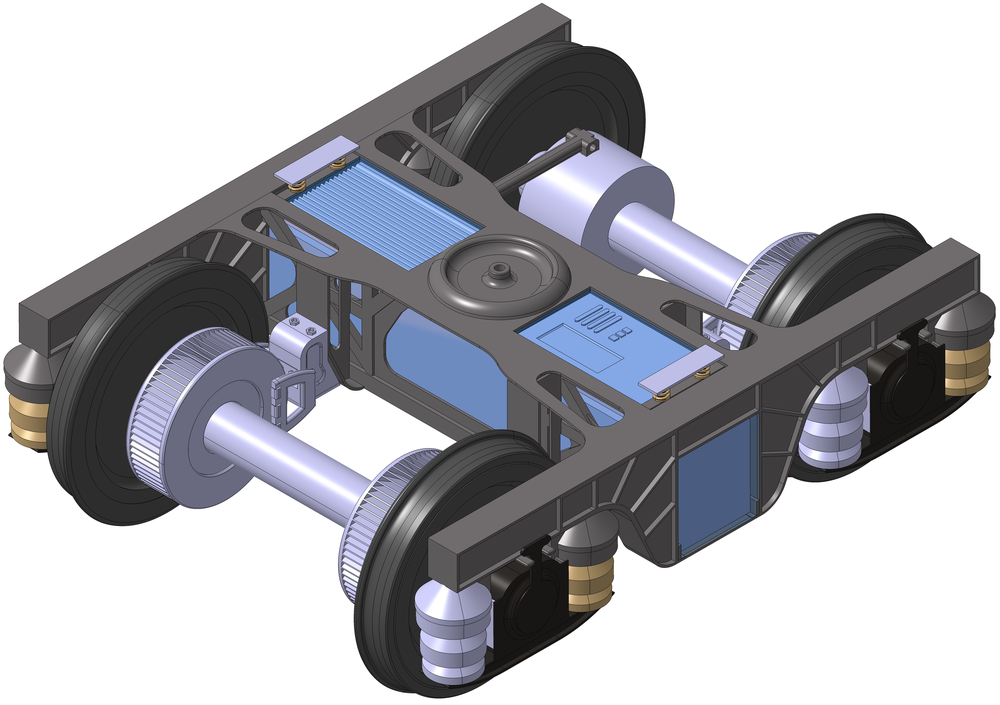

Currently, either shunting locomotives or capital-intensive dual-mode locomotives are necessary for shunting and last-mile journeys. Particularly in single wagonload transport (EWL), this entails complex logistical procedures involving numerous trips by manned locomotives, resulting in high fuel costs, emissions, time consumption and low productivity of resources and personnel. The objective of TP4000 is to develop powered bogies to enhance flexibility and streamline processes in rail freight transport. This initiative aims to enable the retrofitting of existing freight wagons with self-sufficient driving capabilities. Depending on the specific requirements and the balance between costs and benefits concerning battery capacity, propulsion power and payload, additional routes can be covered. This allows for autonomous transport, if needed, for the 'last mile' to the destination, or for one equipped wagon to drive several wagons. The goal is to conceptualise a novel type of fully integrated, lightweight powered freight wagon bogie. This bogie serves as a plug-and-play solution encompassing all necessary hardware for autonomous freight wagon operation, including the drive unit, energy storage unit and computing units.

Beyond the ProCo project, close cooperation exists with other projects in the programme themes of rail transport (InTra, TraCo and RoSto), transport systems (Vmo4Orte) and road transport (FFAE). At European level, the ProCo project is closely linked to the Europe's Next Rail Joint Undertaking and the FCH2RAIL project funded by the Clean Hydrogen Partnership.