This applies to both the mechanical architecture and the interior design of rail vehicles. From the point of view of passengers, manufacturers, operators, public transport authorities and politicians, a wide variety of requirements are placed on a rail vehicle. These requirements come from the areas of comfort, efficiency, economy, ecology, attractiveness and sustainability. Depending on the point of view, a different focus and a different weighting of the requirements can be observed. In this context, the Rolling Stock (RoSto) project is developing interlinked innovative and novel technologies, methods and processes for the development and design of railway vehicles. The aim is to be able to optimally fulfil all the requirements of the various stakeholders for a rail vehicle. Embedded in the overall railway system, its attractiveness, efficiency, competitiveness and performance are significantly increased.

In order to fulfil these requirements for future rail vehicles, the RoSto project focuses on the following aspects:

- Development, realisation and evaluation of user-centric interior concepts

- Development of digital structural development methods using AI-based methods

- Use of resource-saving and sustainable materials

- Influence of aerodynamics on the design of rail vehicles

- Increased safety by reducing aerosol dispersion as well as adapted decontamination concepts and anti-microbial surfaces in the interior

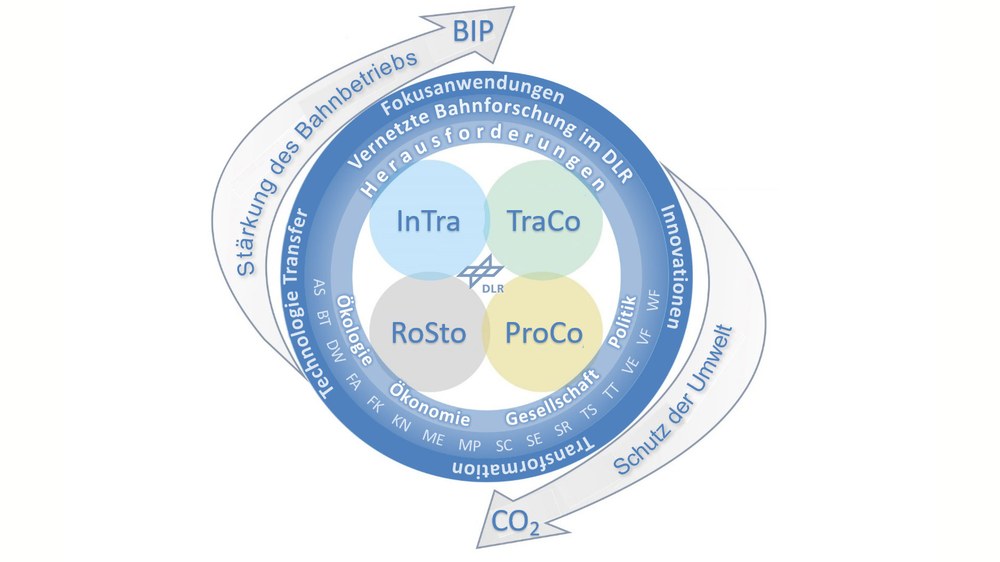

Furthermore, relevant topics will be derived from the target image in the future and synergy effects in relation to the other projects in the programme themes of rail transport (InTra, TraCo and ProCo), transport system (Vmo4Orte) and road transport (FFAE) will be addressed. At European level, the RoSto project is linked to the Europe's Next Rail Joint Undertaking and the CORAERO project.

Projects and sub-projects

RoSto is funded from DLR's own resources. 6 DLR institutes and research facilities are involved. The project is led by the Institute of Vehicle Concepts. The work is being carried out in three interlinked sub-projects (TP). Each of the three sub-projects is headed by a sub-project manager.

TP1000 aerodynamics

SP 1000 includes work on the influence of aerodynamics on the design of rail vehicles. This includes both the influence of the design of pantographs on their efficiency and wear as well as issues relating to the topic of optimised energy efficiency through a correspondingly optimised vehicle design. Extensive measurement campaigns are planned in a real environment. Both passenger and freight vehicles will be analysed.

TP2000 vehicle structure

SP 2000 includes work on the design of the mechanical vehicle structure. A particular focus is on the integration of AI-based methods into the development and design process with the aim of automating this where possible. Another focus is on the use of alternative, sustainable materials for structural components. Linked to this is work on the development of a design methodology for car body structures, which on the one hand enables the standardised strength verification of fibre composite structures and on the other hand maps the loads resulting from real operation as accurately as possible.

TP3000 interior

TP3000 includes work on user-centred interior design. This includes work on individual comfort zones with corresponding air conditioning, the development of an interior concept for evaluating comfort through test subject trials, the development of concepts for reducing aerosol dispersion, taking into account the microbial evaluation of air and surface samples, as well as adapted decontamination concepts and simulation-based procedures for air conditioning. The results will be realised with the help of a physical demonstrator. An important prerequisite for this research work is the use of the DLR's Generic Train Laboratory Göttingen (GZG).

Duration

2022 to 2025

Budget

approx. 6,9 Mio. €