Joining laboratory

Blind riveting tool | |

|---|---|

Areas of application and unique characetristics: | Production of joints |

Pneumatic-hydraulic manual setting tool | |

Adjustable rivet nail extraction | |

Secured against kickback | |

Noise insulated | |

Manufacturer: Wilhelm Böllhoff GmbH & Co. KG | Type: P 2002 |

Hardness and strength testing machine | |

Areas of application and unique characetristics: | Low-destructive component testing |

Mechanical quality assurance of components and samples according to the indentation method DIN-SPEC 4864 | |

Determination of the yield curve, yield strength, tensile strength and hardness | |

Suitable for a wide range of steel, aluminium, nickel and titanium alloys | |

Manufacturer: Imprintec GmbH | Type: i3D COMPACT |

High-speed bolt setting device | |

Areas of application and unique characetristics: | Production of joints |

Joining without pilot hole with one-sided accessibility | |

Flexible use for mixed, multilayer and hybrid joints | |

Pneumatic-hydraulic manual setting tool | |

Manufacturer: Wilhelm Böllhoff GmbH & Co. KG | Type: RIVTAC® Portable |

Equipment for adhesive joining | |

Areas of application and unique characetristics: | Scientific gluing of joining samples according to standard and of prototype components |

Mechanical, manual application | |

Pneumatic application | |

Electric, heated glue gun | |

Adhesive cartridge preheater | |

Silicone casting moulds substance samples | |

Universal gluing device for shear and head tension specimens | |

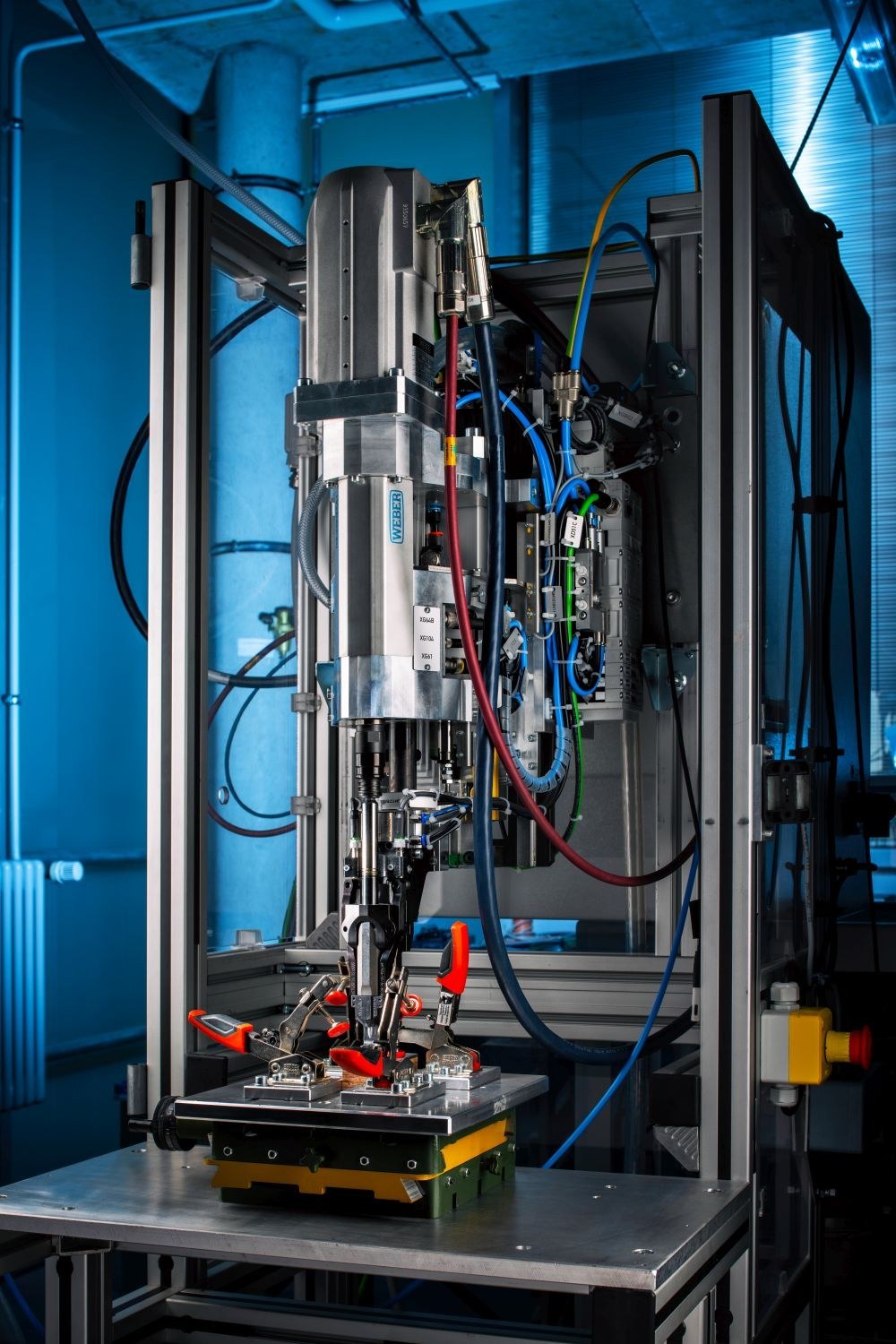

Flow-drill screwing system | |

Areas of application and unique characetristics: | Production of joints |

Joining without pilot hole with one-sided accessibility | |

Flexible use for mixed, multilayer and hybrid joints | |

Detachable and repeatable multiple times | |

Manufacturer: WEBER Schraubautomaten GmbH | Type: RSF25 |

Self-piercing riveting and clinching system | |

Areas of application and unique characetristics: | Production of joints |

Joining without pilot hole with two-sided accessibility | |

Flexible use for mixed, multilayer and hybrid joints | |

No thermal influence | |

Manufacturer: Wilhelm Böllhoff GmbH & Co. KG | Type: MTF-FC / SC 2505 P 75 S |