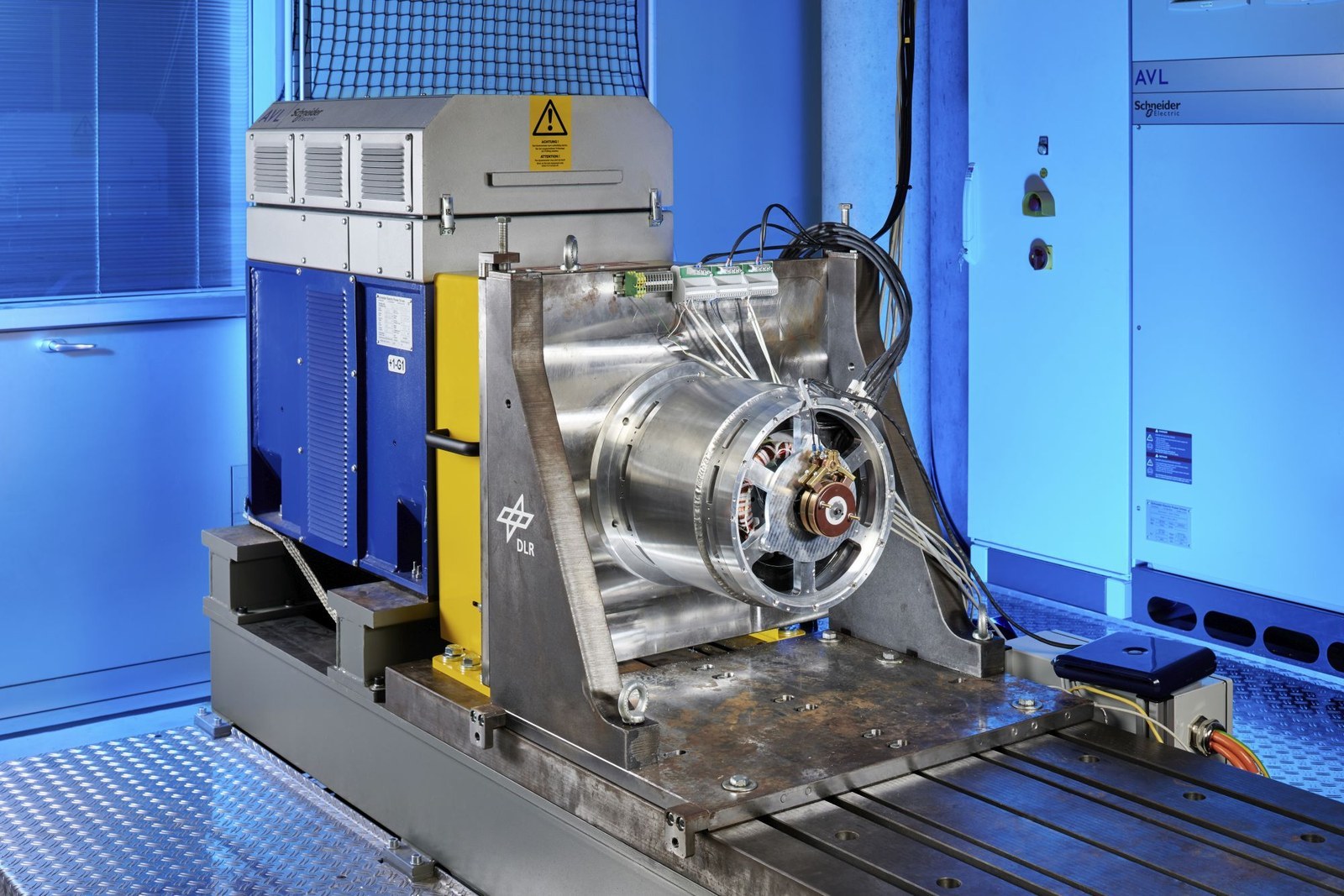

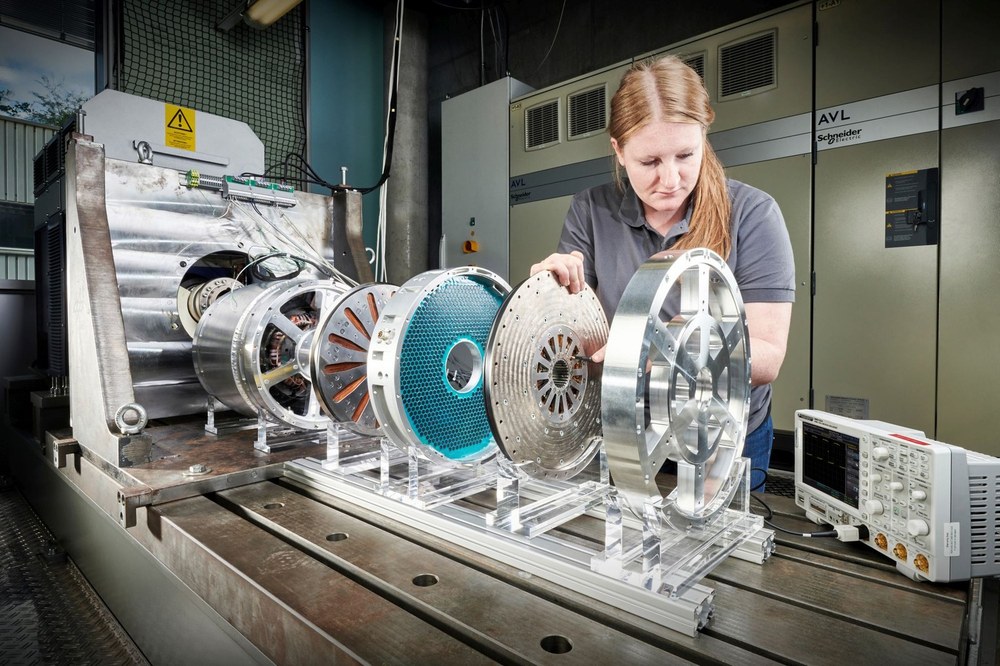

Electric motor test bench

Areas of application | |

|---|---|

Electrical characterisation of electrical machines and converters | |

Mechanical measurements of rotating machines | |

Power and efficiency measurement | |

Thermal measurement, cycle evaluation, Energy Drive Lab | |

Technical data | |

Maximum drive power | 220 kW |

Maximum speed | 12,000 rpm |

Maximum torque | 525 Nm |

Shaft connection | Taper bush |

Available components | |

Inverter | CAN, RS422 |

Input voltage | 0-850 V |

Power | 160 kW |

Output voltage | 560 V AC |

Output current | 270 A Eff |

Rotary encoder | Endat compatible |

DC-Source | |

Power | 250 kW |

Current | 600 A |

Voltage | 5-1000 V |

Cooling water temperature control | |

Flow rate | up to 60 l/min |

Pressure | up to 38 bar |

Temperature range | 20-90 Degrees |

Auxiliary voltage | 5, 12, 24, 48 and 72 V |

Measurement technology | HBM GEN7ta (CAN-Recording, 6 Phases) |

Sampling rate | 2 MS/s |

Software | Perception |

Sensors | LEM-Transducer CT500 (500Aac) / CT100 (100Aac rms) |

Torque | HBM T40B |

Temperature | Type K thermocouples |