Dynamic High Strain Component Test Facility – Crash Test Facility

The institute develops new vehicle concepts and technologies against the background of future requirements for the transport system. The research field of vehicle architectures and lightweight construction concepts researches and develops sustainable construction methods and vehicle structures.

Validation tests of the crash behaviour of components are necessary in the research and development process. Due to the high costs of complete vehicle tests and in the case of new structures, usually non-existent complete vehicle structures, the component crash behaviour is investigated in quasi-static or dynamic component tests.

Component tests can be used to validate simulation models and optimise model behaviour. In order to adapt to the real application, it is important to design the boundary conditions in the component test in such a way that the component behaviour from the overall vehicle environment is simulated with sufficient accuracy. A process model developed at the institute can be used for the time-efficient and requirement-orientated development of robust component crash test benches.

Test system details:

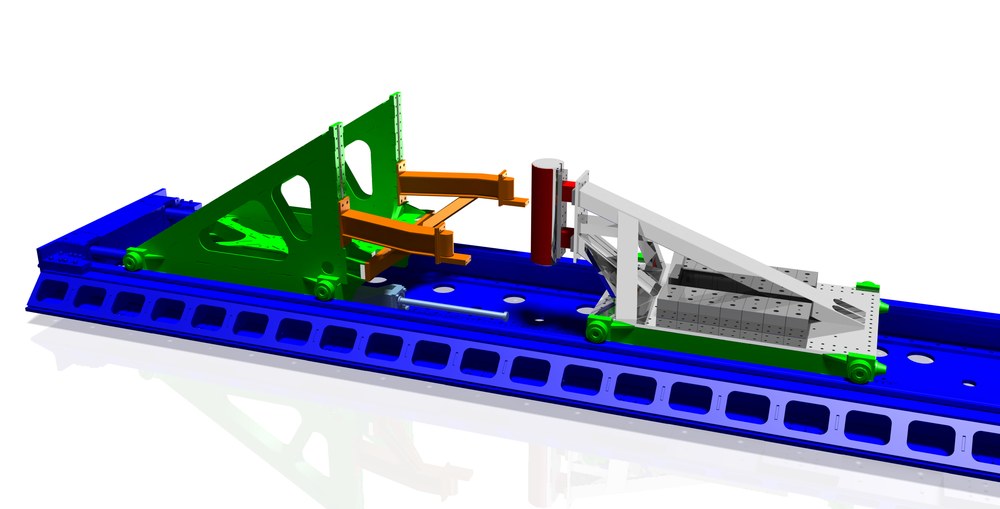

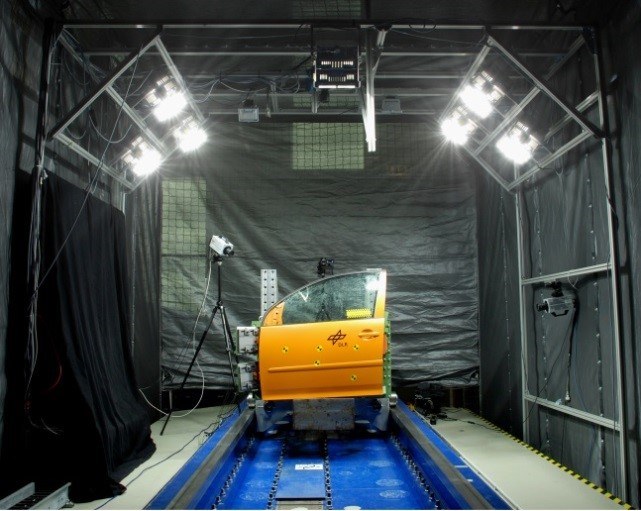

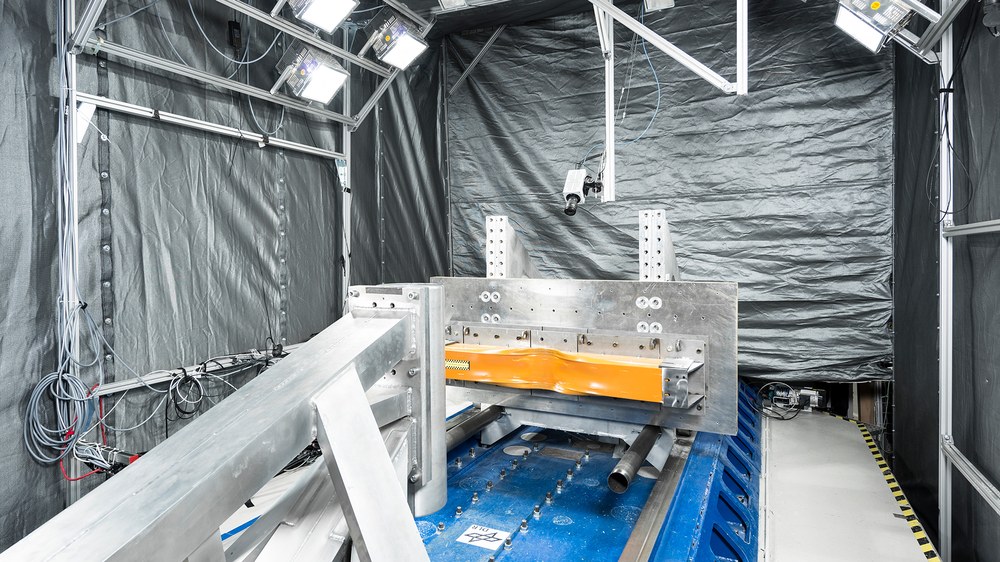

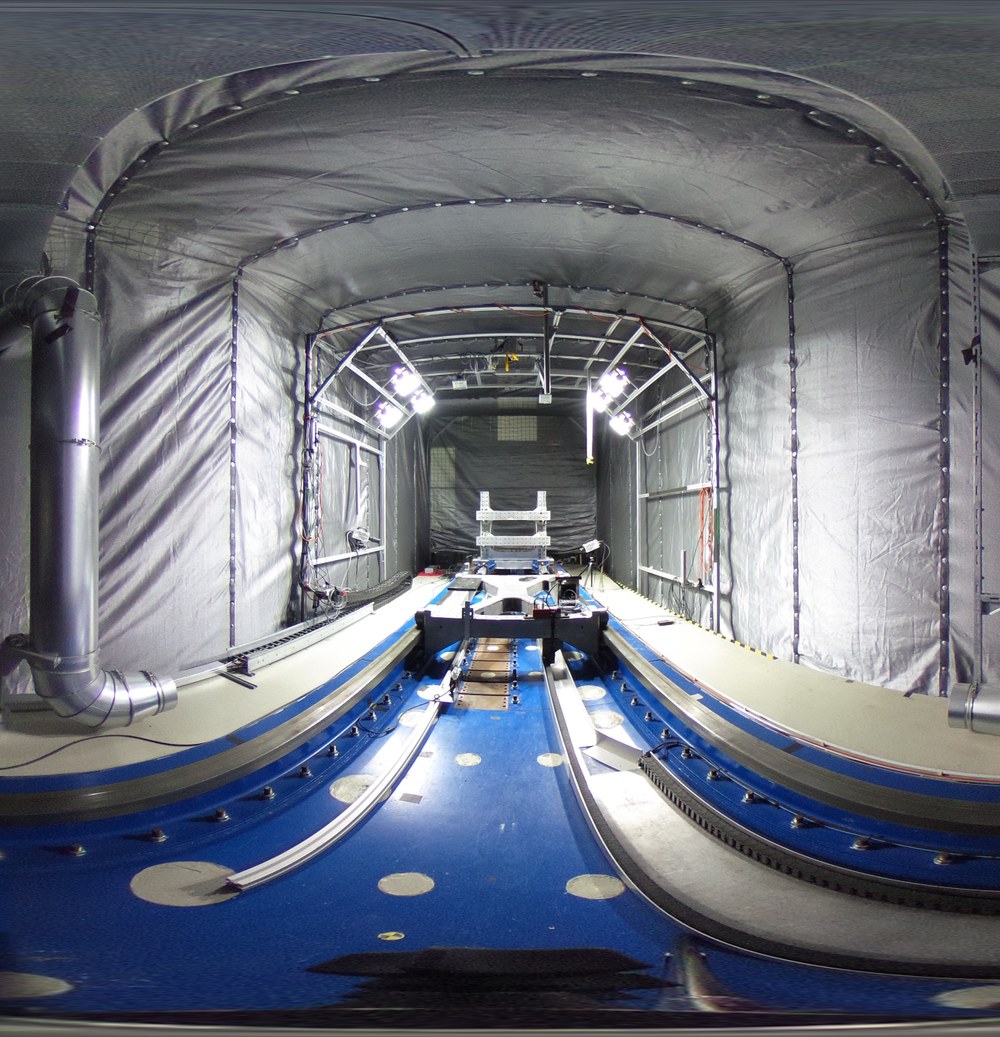

The system is designed as a modular two-slide system in order to be able to carry out as many crash configurations as possible. The test specimen is attached to the stationary slide (green), for example. The pneumatic cylinder (orange) accelerates the impactor carriage (red) linearly, guided via the rail system (blue), onto the test specimen

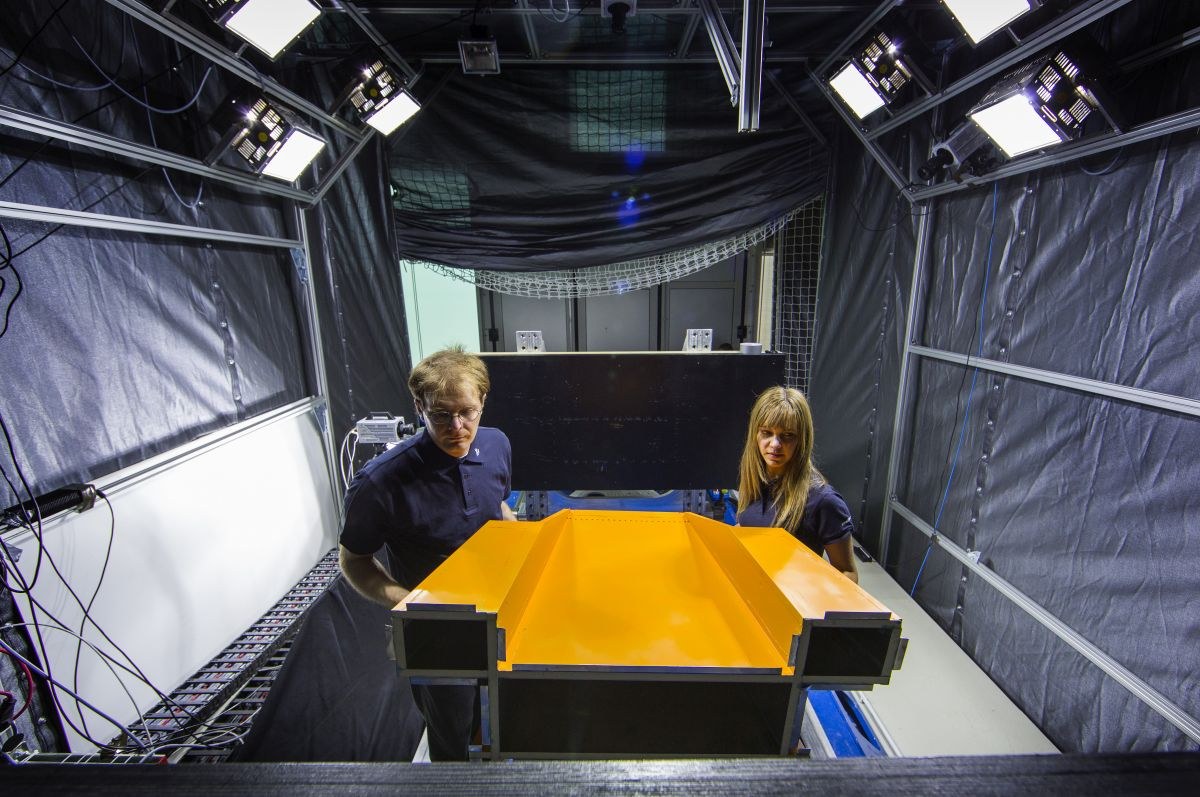

Construction of the crash system

| |

|---|---|

Dimensions of the test room | 2 x 3.5 x 3 m3 (L x W x H): |

Speed | 64 km/h at 1300 kg |

Crash energy | max. 205 kJ |

With its modular design, the sled system enables flexible adaptation to various test scenarios with a wide range of requirements (such as a rigid impact, evasive movement in a side impact and much more). Thanks to its lightweight construction, the impactor carriage makes it possible to carry out tests with low kinetic energy at high speed. With a total test specimen mass of 1.3 tonnes, the impactor carriage can be accelerated to 64 km/h using the pneumatic cylinder.

Unique selling points

- Modular system for various crash configurations

- Linear guided sled system for scientific simulation/test alignment

Measurement and evaluation technology equipment

- Acceleration sensors, 3- and 6-axis force sensors (up to 400 kN)

- Strain gauges, draw-wire potentiometer

- Onboard data acquisition system (max. 100 kHz)

- High-speed cameras, 2 x colour, 1024 x 1024 pixels @ 1,000 fps, 2 x colour, 1024 x 1024 pixels @ 2,000 fps, 1 x colour, 1920 x 1440 pixels @1,125 fps

- Software for 2D & 3D point tracking in the HS images

- 3D scan before and after test execution possible

Project work

- Carrying out and analysing sled tests including simulation comparison, transfer of test data in the form of

- Photo documentation / data (e.g. CSV files) / videos

- Self-running application with synchronised videos, measurement data

- Development of component test benches for internal validation projects and external customers with a process model developed for this purpose for the conception and design of component crash tests