3D Printing for Low-Cost Space Components

3D Printing for Low-Cost Space Components (3D-LoCoS) | |

|---|---|

Duration | 01.01.2019 – 31.12.2021 |

Field of application |

|

Budget | 2.7 million euros |

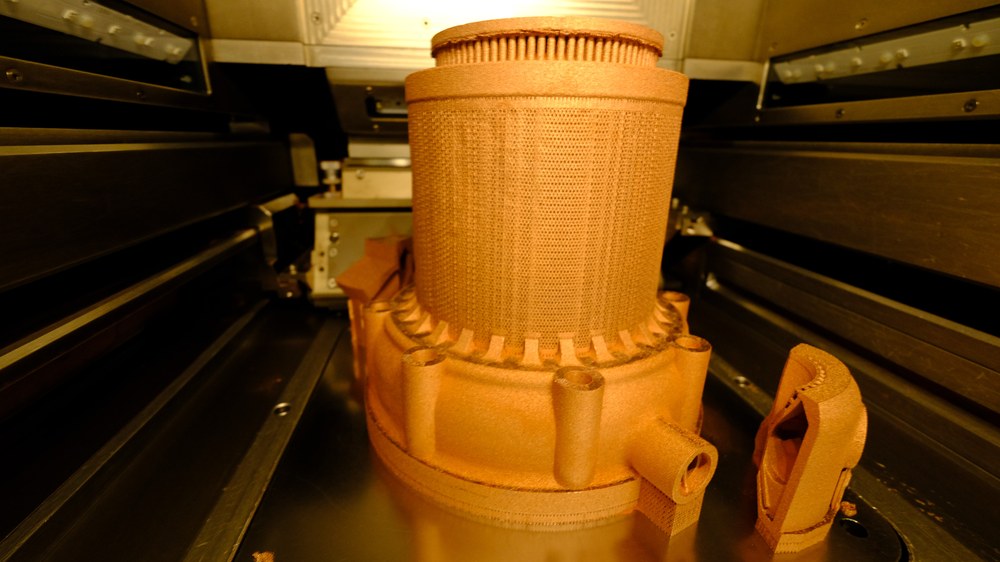

Scientists at the German Aerospace Center (DLR) are focusing on these parameters in the "3D-LoCoS – 3D Printing for Low-Cost Space Components" project. The focus is on the further development and application of metal additive manufacturing, i.e. 3D printing processes. This enables technology demonstrators for space components to be produced more cost-effectively and more quickly.

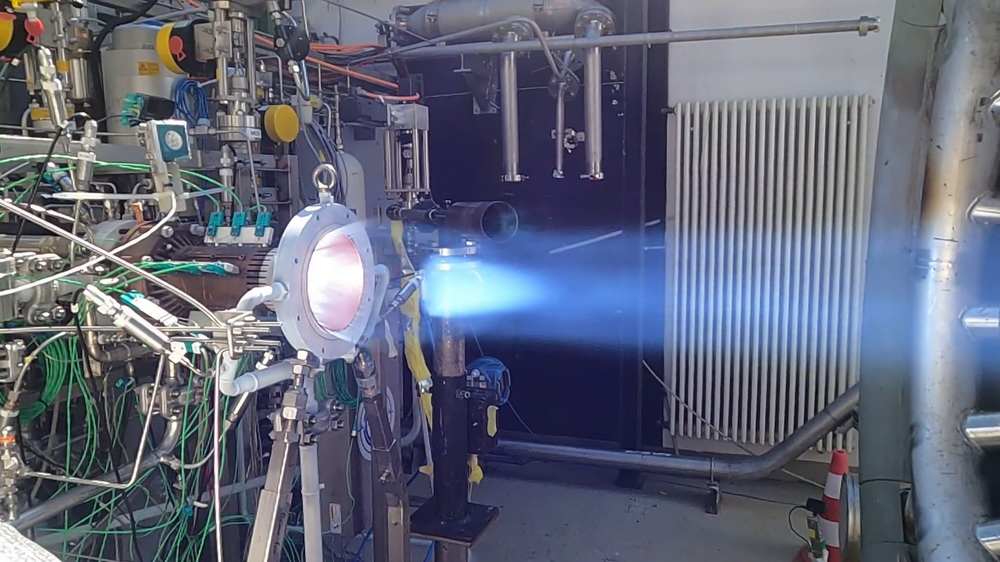

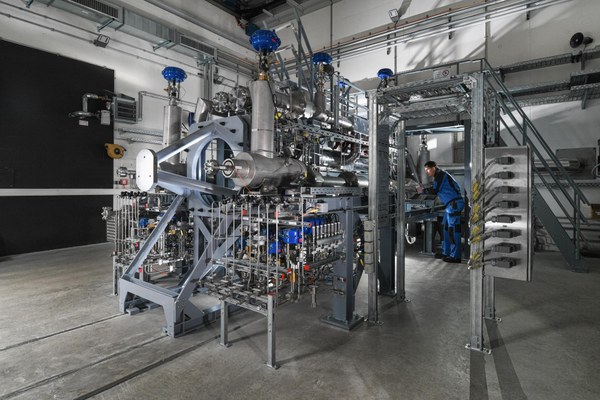

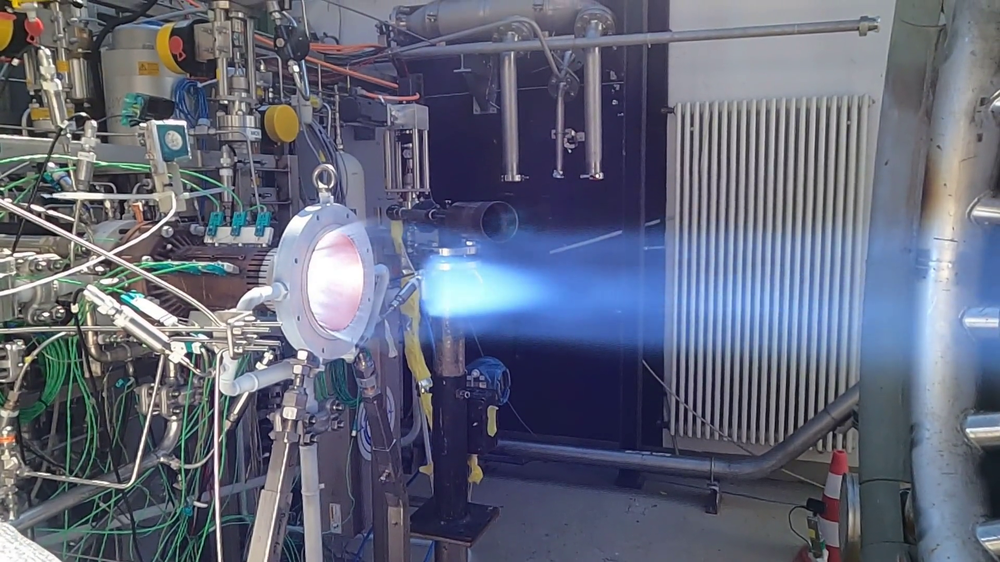

New production process on the test bench P8

Hot run tests at the P8 research and technology test bench in Lampoldshausen have shown that both the design and the manufacturing process of the 3D-printed combustion chamber with a thrust of 25 kilonewtons were successful. "With six hot run tests, we were able to demonstrate the great potential of the new design and functionality of the 3D-printed combustion chamber," says Dmitry Suslov. "Now we want to quickly bring this technology into industrial application. The test series has proven that additive manufacturing offers a wide scope for the design and construction of engine components." Innovative design methods based on Artificial Intelligence (AI) have also been used throughout the project – from the design of the combustion chamber to testing on the test bench.

Your consent to the storage of data ('cookies') is required for the playback of this video on Quickchannel.com. You can view and change your current data storage settings at any time under privacy.