Floating peas and a patented clothes hanger

In the years immediately after the end of World War II, aeronautics research and the construction of aircraft in Germany were banned by Allied Control Council Law No. 25. As in the wake of World War I, researchers at DLR's predecessor organisations had to think up creative ways to continue their work in the field of applied natural sciences despite the restrictions and find sources of income to finance their activities.

After World War II, the three main predecessor organisations of DLR – the German Research Institute for Aviation (Deutsche Versuchsanstalt für Luftfahrt; DVL) in Berlin-Adlershof, the Hermann Göring Research Institute (Deutsche Luftfahrtforschungsanstalt; LFA) in Braunschweig and the Aerodynamics Research Institute (Aerodynamische Versuchsanstalt; AVA) in Göttingen – came under the control of the victorious powers, which controlled their research facilities and employees for their own purposes. The British, for example, instructed select scientists from the LFA and the AVA to detail their research activities during World War II in writing. At the same time, the wind tunnels and test facilities at the three institutions were gradually dismantled or destroyed in accordance with the Potsdam Agreement. The research institutions gradually ceased operations.

Aerodynamic research for agriculture

While some of the AVA staff were able to transfer to the Kaiser Wilhelm Institute (KWI) for Fluid Mechanics in Göttingen following completion of their work for the British, LFA employees had no choice but to look for new employment. The director of the LFA, Hermann Blenk (1901–1995), initially took up a role at the Federal Research Institute for Agriculture (Bundesforschungsanstalt für Landwirtschaft; FAL), which was established on the LFA site. As an aerodynamicist, he possessed a superb understanding of fluid dynamics processes and was therefore entrusted with two research tasks at the FAL: determining how seeds could be cleaned and sifted using wind and investigating the transport of grain, hay and straw via 'pneumatic conveyance', that is, through a series of pipelines pushed by a stream of air or gas.

A number of AVA employees followed similar trajectories when their institute was taken over by the Kaiser Wilhelm Institute for Fluid Dynamics. Their knowledge of aerodynamics meant that they were assigned to the task of developing a floating sorting process for peas on behalf of a Hamburg company. Several scientists who had worked at the AVA Institute of Cold Research during World War II – where they investigated ice formation on aircraft wings and tailplanes at high altitudes – were given the opportunity of moving to the KWI. After the war, they helped the Göttingen slaughterhouse upgrade its refrigeration system and developed a quick-freezing process for food.

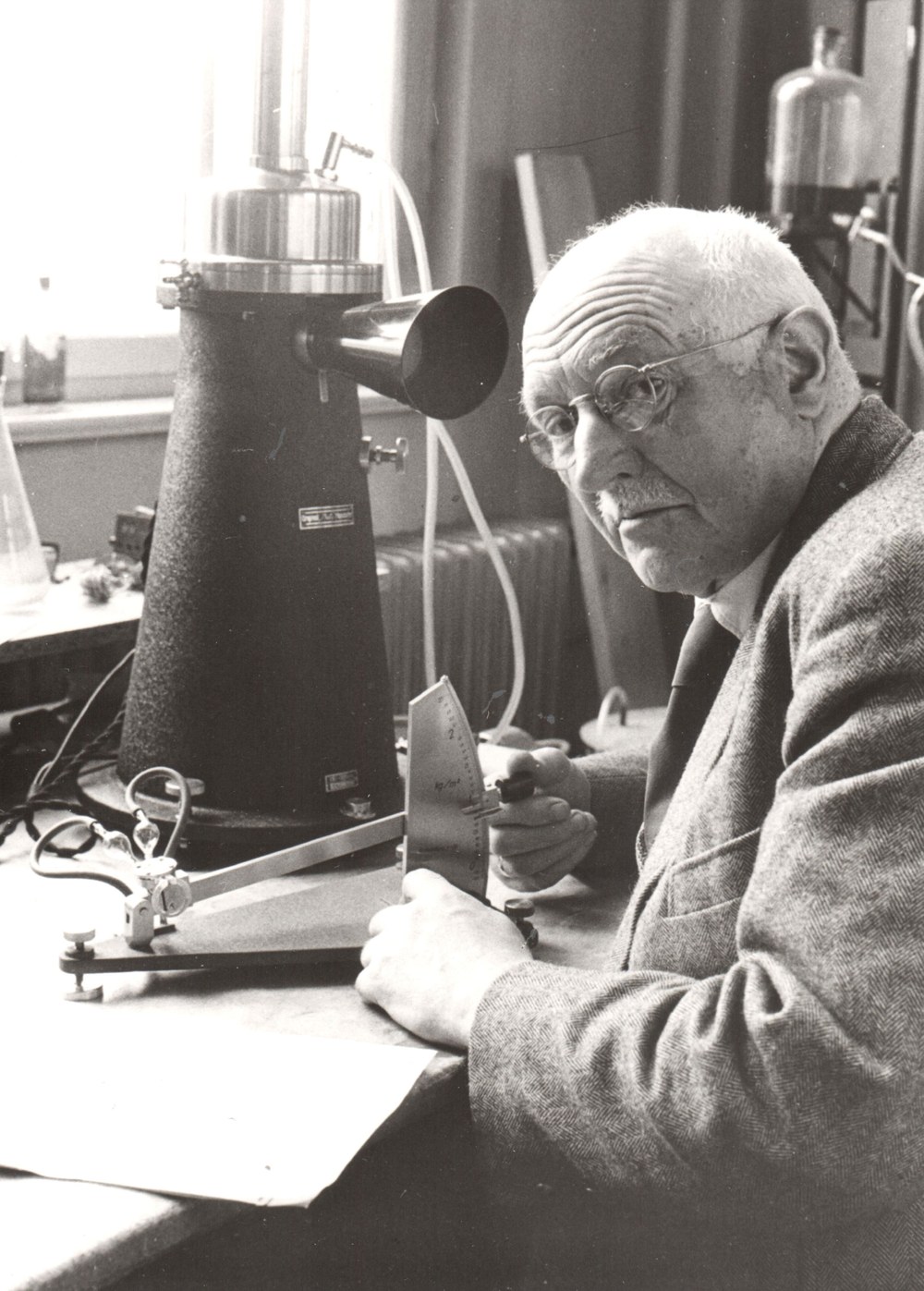

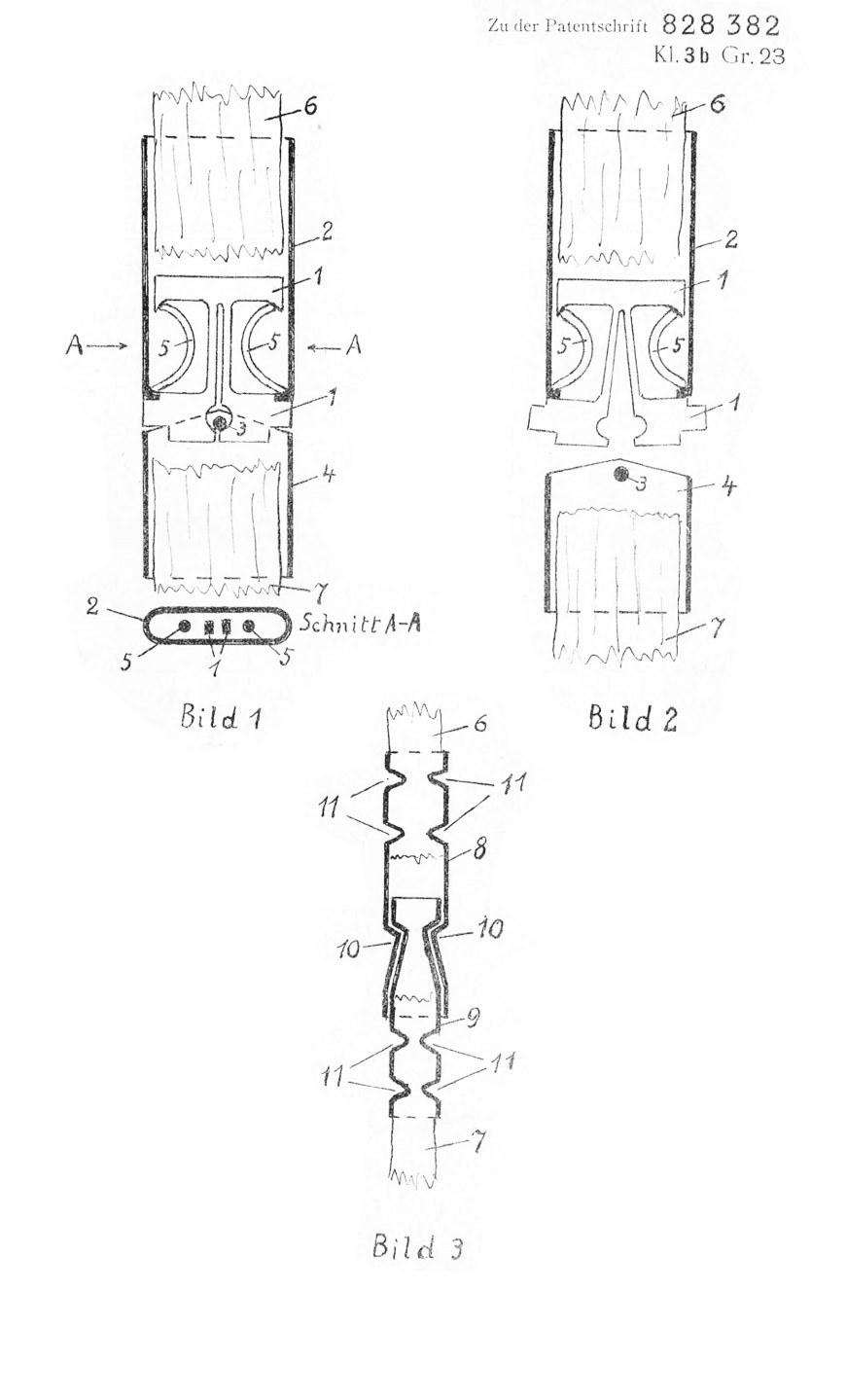

These research activities were not only authorised by the British but actively encouraged as civilian-focused tasks that contributed to the rebuilding of public life within the British zone of occupation. There was also time for private research, as long as it did not violate Law No. 25. Albert Betz (1885–1968), former head of the AVA and from 1947 director of the KWI for Fluid Mechanics and later the Max Planck Institute for Fluid Mechanics, developed a new type of clothes hanger which he successfully patented in 1949. As he did not have the time to market it himself, he hoped that his nephew would take on the project. Although the nephew was keen to find a buyer, he was also very busy working as a lawyer, so negotiations with interested companies took a long time. To make matters worse, Betz had very exacting expectations of the quality of the clothes hanger. He was adamant that it should be made of highquality material that would ensure it could be used for as long as possible. Yet the interested companies did not have such high standards. As far as they were concerned, such an item did not have to last a lifetime, and they were more than happy to boost the manufacturing companies' margins by opting for alternatives. Ultimately, the companies refused to use the appropriate materials in production. This marked the collision of two worlds – science and commerce. Unsurprisingly, this particular clothes hanger did not find its way into series production, so it did not end up appearing in wardrobes.

As the examples outlined here illustrate, in the late 1940s and early 1950s researchers had to transfer their skills and scientific strengths to areas that lay outside their core area of scientific expertise. This was far from easy, but it gave them a point of entry into new areas of work and ways of thinking, from which they benefited in the long term.

An article by Dr. Jessika Wichner from the DLRmagazine 175