Robot workmates

Tobias Blaser/Lichtwerk

Building an aircraft takes time. In contrast to the automotive industry, where over 1000 vehicles can leave a factory on any given day, Airbus builds only around 60 aircraft per month. Manual work is still involved – structures must be cleaned and stiffening elements pre-assembled and fastened in place. The processes involved require a high level of accuracy and are time consuming. New concepts and technologies can help increase the amount of work that can be automated. Together with partners from industry and research, DLR is investigating what cooperation between human and machine might look like.

The fuselage of a medium-haul aircraft such as the Airbus A320 consists of several segments, called sections, which are made up of several shells. To prevent the metal outer skin of a shell from buckling, it is held in place by a support structure, similar to that of a ship. Before a worker can assemble the elements of the support structure, which can be up to seven metres long, the outer skin must be cleaned and an activation liquid and sealing compound applied. Only then is the support element fitted and pre-assembly completed. During the final assembly, highly skilled workers must fasten up to 1000 rivets per segment to firmly connect the components. This is followed by a final quality inspection.

"A huge benefit for us was the fact that we had access to the data and were working with components that would fly on real aircraft."

Dr. Marcin Malecha, Staff member at DLR's Center for Lightweight-Production-Technology and Agreed project manager.

Automation in pre-assembly and final assembly

These two process steps – the pre-assembly and final assembly of a shell – formed the core of a research project called 'Agreed'. DLR was the commissioning party for the project and worked together with the aircraft manufacturer Premium Aerotec to digitalise and automate the processes involved. Premium Aerotec manufactures fuselage parts for various types of Airbus aircraft. Pre-assembly takes place in Augsburg and final assembly in Nordenham, Lower Saxony. "A huge benefit for us was the fact that we had access to the data and were working with components that would fly on real aircraft. These are normally confidential," says Marcin Malecha, who works at the DLR Center for Lightweight-Production-Technology (ZLP) and led the project for DLR. "We also worked together with experts from production, which has enormously increased levels of acceptance for the technologies developed. The results will greatly benefit our future research."

Video: Fully automated pre-assembly in the Agreed project

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

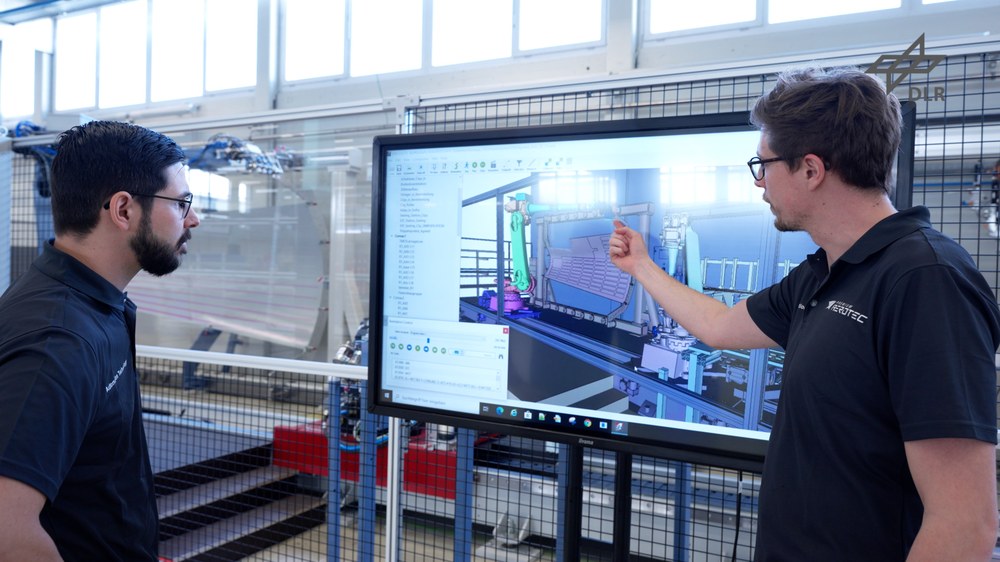

Planning and development in the digital factory

The team started by developing what are known as 'digital twins' for pre-assembly in Augsburg and final assembly in Nordenham. This accelerated process development, as all tools could be tested prior to prototyping and the robotic movements programmed before the equipment was physically built. The virtual environment represented every step of production. The digital twins were the basis for the daily work plan, showing how many workers and robots would be in use. The experts themselves were equipped with augmented-reality headsets. These displayed the work steps and assistance options, and controlled the distribution of tasks between humans and robots. Artificial intelligence was used in some process steps, taking over the programming, for example, in the complex threading movements of clips during pre-assembly.

Video: Human-machine collaboration in the Agreed project

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

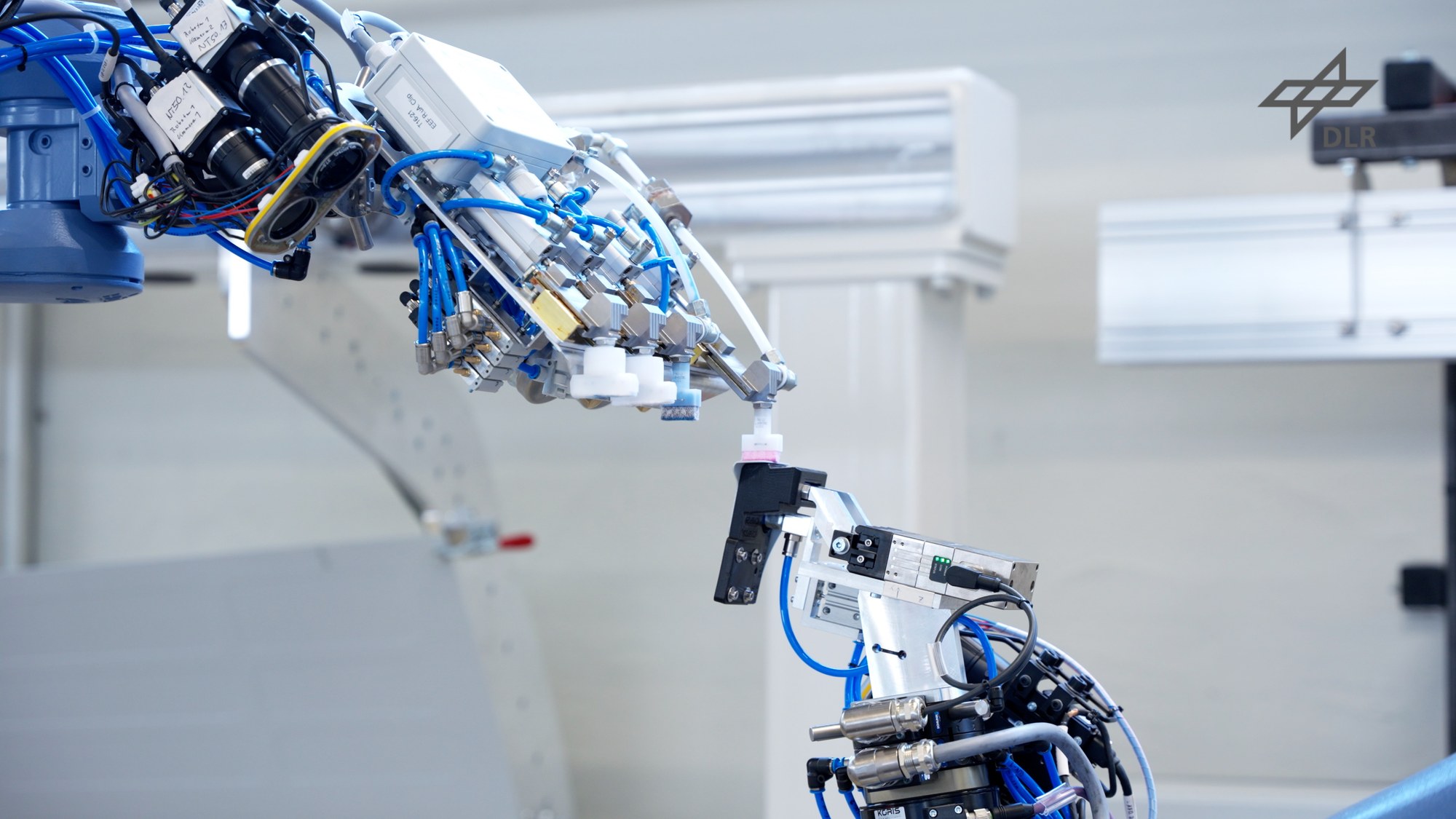

At other points, the robots moved completely autonomously, such as during drilling and completeness inspections. The drilling and riveting tools were specially developed and brought to their respective stations together with lightweight robots on mobile transport units. Their routes were also controlled using the digital twin. In parallel, the researchers designed the robots and tools needed to clean the outer skin and fix the support structures. Here, too, the experts benefited from the digital twin. "The program showed us directly whether our tool was the right size or in the right place, and where we still needed to make adjustments. This saved us from having to build many prototypes," adds Malecha.

Two successfully tested concepts

During the project, the team was able to completely automate the pre-assembly process – it ran entirely without human intervention. Human and machine worked closely together during the final assembly. A robot took over quality assurance, comparing the position of the rivets and drill holes with the digital construction plans using images from mounted cameras. A specialist only intervened to assess whether corrections should be made if a position did not match up.

The systems are currently running on Premium Aerotec's research facilities. "It will probably take another two to three years before the first automated or cooperative station is used in production. However, there is a lot of interest from industry in the technologies developed in the Agreed project," Malecha says. And if he has his way, the project will not end here. Together with Premium Aerotec, a concept is set to be developed for a station where robots work on several components in parallel and follow the section assembly. Malecha is confident of success: "Automation might not be suitable for all processes, but we have not yet exhausted our possibilities."

The Agreed project at a glance

Agreed was an internal DLR project. The aim was to develop automation solutions for flexible and expandable shell assemblies using digital intelligence. In addition to technological research, DLR also assumed the administrative and planning roles. The work was coordinated in cooperation with the general contractor Premium Aerotec GmbH. Other participants from industry and science were subcontracted for extensive research work: Broetje Automation GmbH, Viscotec GmbH, University of Wuppertal, Fraunhofer IFAM, Fraunhofer IFF and Capgemini.

An article by Marcin Malecha und Julia Heil from the DLRmagazine 171