Awakening the sleeping giant

In public discussions about the energy transition, the field of sustainable heat use has long been in the shadows. The focus has been on electricity from renewable energy sources, and how best to generate and distribute it in large quantities. For those outside a relatively closed circle of house builders and renovators dealing directly with heating technology, building insulation and heat pumps, the 'heat transition' has passed largely unnoticed – until now.

Due to the current uncertainty of supply, especially of natural gas, citizens, politicians and businesses must face the question of how industrial processes, which often require a great deal of heat, can be kept running. The same dilemma looms over heating for public and private buildings. Meanwhile, the political and social consensus to put a stop to global climate change demands a new look at our heat supply, with a view to adopting more sustainable and sometimes completely new technological solutions. Fortunately, DLR has its finger on Germany's heat pulse with its energy systems analysis. Together with partners from science and industry, DLR is researching innovative technologies for climate-friendly heat from renewable energy sources and also supporting spin-off projects.

"If we succeed in intelligently linking technologies for climate-friendly heat supply with the electricity sector, with its heavy use of wind and photovoltaics, the heat transition could make an immense contribution to the energy transition as a whole."

Evelyn Sperber, DLR-Institute of Networked Energy Systems

A look at the numbers – the energy giant we call heat

More than half of the energy consumed in Germany is used to provide heating and cooling – including process heat for industrial processes. Forty percent of energy-related carbon dioxide emissions are generated in this context. Heating and hot water in private households also have an enormous impact, being responsible for around 80 percent of energy consumption. In view of recently rising gas prices, the financial burden has grown enormously.

"Compared to the 'energy transition', however, attention to the 'heat transition' has been rather modest until now," says Evelyn Sperber from the DLR Institute of Networked Energy Systems. She works in the Energy System Analysis department and researches the interactions between the heat supply of buildings and the electricity supply of the future. The share of heat provided by renewable energies is around 15 percent. The lion's share comes from biomass, with wood being the principal energy source. However, biomass is only available in limited quantities, is not necessarily climate-neutral and its cultivation can compete with food production. Buildings of all kinds are still primarily heated with fossil fuels – natural gas or oil – often using outdated systems. "If we succeed in intelligently linking technologies for climate-friendly heat supply with the electricity sector, with its heavy use of wind and photovoltaics, the heat transition could make an immense contribution to the energy transition as a whole," says Sperber, looking to the future.

Energy-efficient building renovation – DLR expertise for analysis and evaluation

In Germany, the building of new housing is not matched by the demolition of old structures. Thus, even if new buildings emitted no carbon dioxide whatsoever, net emissions would not be reduced significantly, with the result that legally-mandated climate targets cannot be achieved. Refurbishing old buildings to improve their energy efficiency is therefore a critical strategy, but in Germany such refurbishment proceeds too slowly and is not sufficiently extensive. Owners and investors shy away from the costs and risks associated with comprehensive renovation, which are often difficult to predict. Quality assurance is difficult because objective testing technologies are lacking or are expensive and time-consuming.

To break these barriers to transformation, DLR is working with an interdisciplinary team on a range of new technologies. In the future, they should allow buildings and districts to be analysed and evaluated objectively, quickly and cost-effectively. "We want to create a precise knowledge base for planning and construction companies, owners and investors. They will be able to call upon this base to derive sensible energy- and cost-efficient refurbishment measures, and also check them qualitatively after completion," says Bernhard Hoffschmidt, who heads the DLR Institute of Solar Research and has successfully initiated, supported and managed several spin-off projects. The jump from research on solar thermal power plants to the analysis of buildings is not as great as one might think. Hoffschmidt and his colleagues have developed a measuring system mounted on a small drone that monitors the status of the often gigantic heliostat fields of solar-thermal power plants. Similar approaches can be used in the future to analyse and evaluate buildings and entire city districts. "At DLR, we already have most of the knowledge, technologies and experience in place," he says.

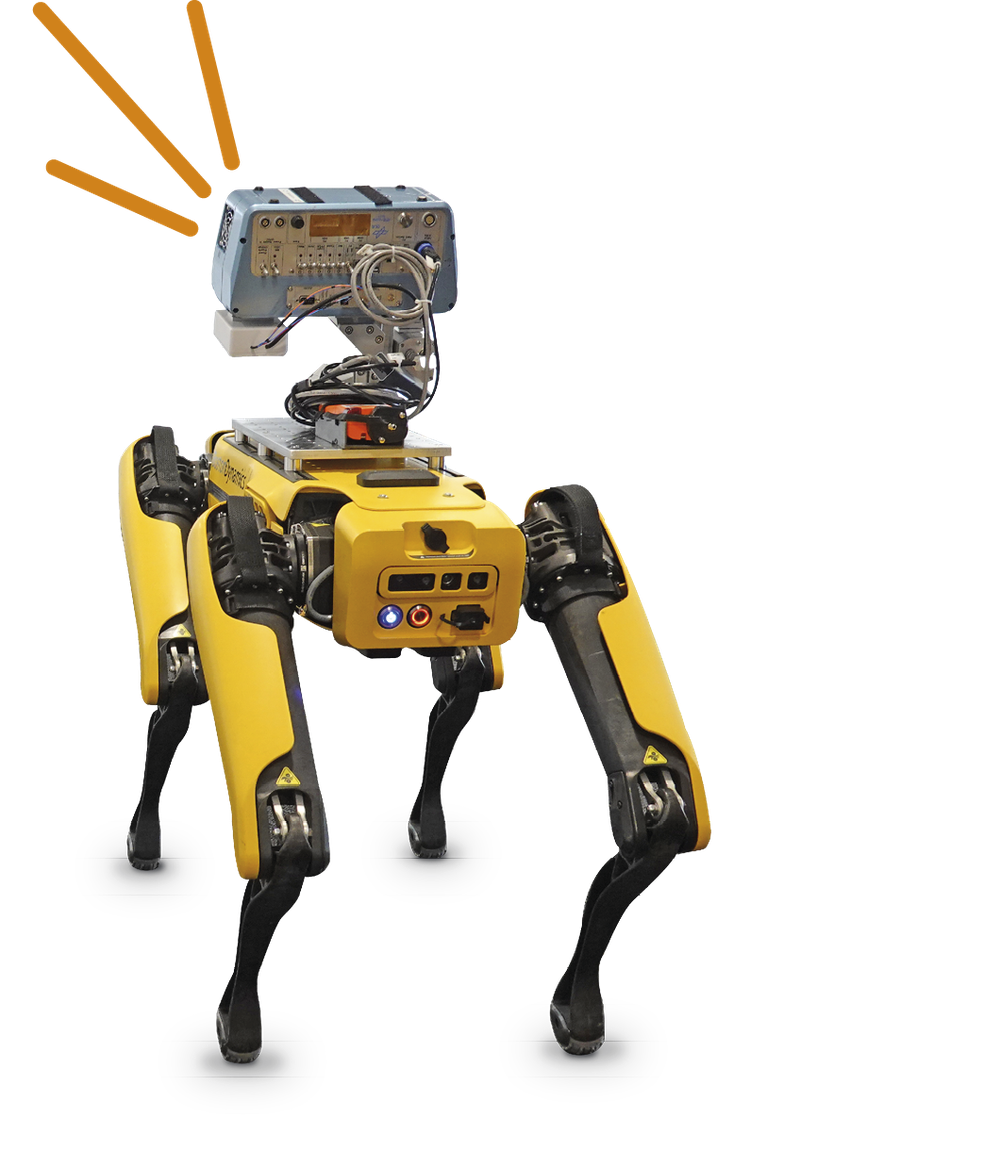

For example, analysis methods from the fields of Earth observation, security and energy research already use sensors that automatically take measurements aboard satellites, aircraft or drones. Many of these sensors could be adapted for use in the building sector. DLR researchers are also testing a special camera system which rides on board a robot dog, from where it can determine the inner geometry of rooms or entire buildings using 3D scans – and can also detect gaps and holes. Hidden wall structures such as cavities, conduits and shafts can be detected with radar and radiometry. With Lumoview Building Analytics, DLR has already launched the first spin-off in this field. Using a portable 360-degree infrared camera system and special software, the spin-off creates three-dimensional building models. These images show thermal properties at a glance, identifying the places where external walls lose the most heat and finding damp spots. The operation can be completed in just minutes, easily and with little training

Heat for neighbourhoods, business and industry – a networked approach

For the energy transition to be successful, the heating sector needs to be thought of in a more networked manner, with existing resources better and more flexibly managed – at all levels and across sectors. This means looking at individual buildings in the context of their surroundings, and coupling air conditioning systems to electricity from photovoltaic panels and thermal collectors. Waste heat from industry and commerce must be used as efficiently as possible, on-site where it is available, while thermal insulation and the expansion of heating networks must be better coordinated. The fields of electricity, heat, industry and mobility will be much more closely linked in the future. In the Wärmewende Nordwest (Northwest Heat Transition) research project, scientists from the DLR Institute of Networked Energy Systems and its partners are investigating the heat transition in the Oldenburg and Bremen regions. The aim is to record and optimise the heating requirements of buildings, neighbourhoods, business and industry in a transparent manner. To this end, the researchers are further developing an existing simulation model to add depictions of heat flows and the different components of the heating network alongside electricity flows.

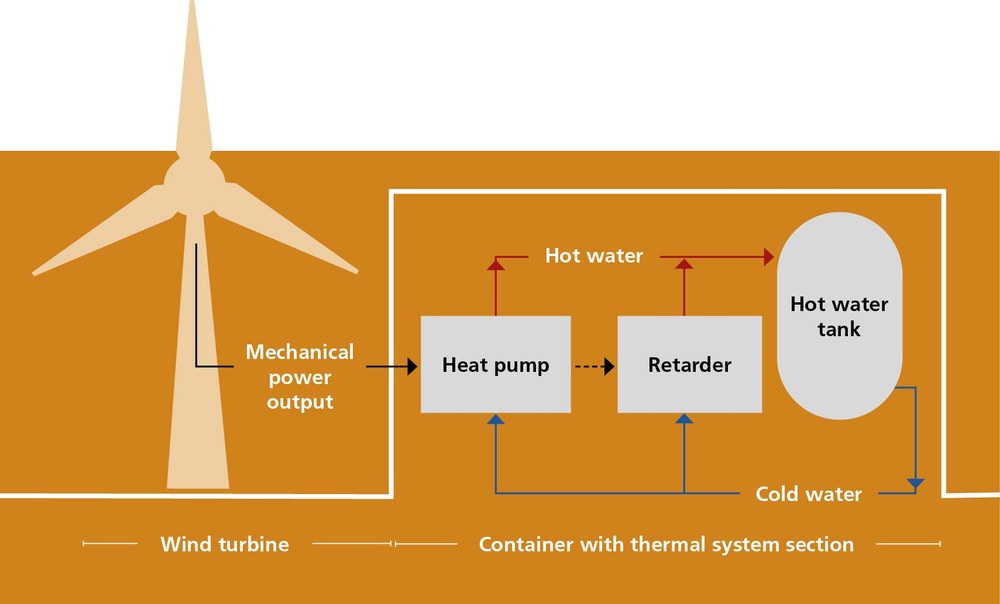

Heating and energy storage – generating heat directly from wind

Wind energy is one of the main pillars of the energy transition. It already accounts for around 20 percent of electricity generation. But heat can also be generated directly from wind – without carbon dioxide emissions and therefore in an environment-friendly manner, relatively easily and inexpensively. Under the heading of 'wind thermal energy' the DLR Institutes of Flight Systems, Engineering Thermodynamics and Networked Energy Systems are researching this previously little-known technology to assess its economic potential and identify possible uses. A first test facility already exists. It consists of a small wind turbine and all the components necessary for heat generation, all packed inside a standard shipping container to be compact and transportable. "Wind thermal energy is one approach to decarbonising the heating sector and making it more flexible. The decisive advantage is the direct generation of heat. Up to now, electricity from wind energy that is not needed immediately has been used to generate heat and store it. This involves an extra step and correspondingly high losses in the conversion from kinetic energy into electricity and then to heat," describes project manager Malte Neumeier of the Institute of Flight Systems. The DLR researchers see potential uses for wind thermal energy wherever heat is required at low and medium temperatures, up to around 300 degrees Celsius. This temperature range covers local and district heating for buildings and many industrial processes.

XXL heat pump – sustainable heat for industrial processes

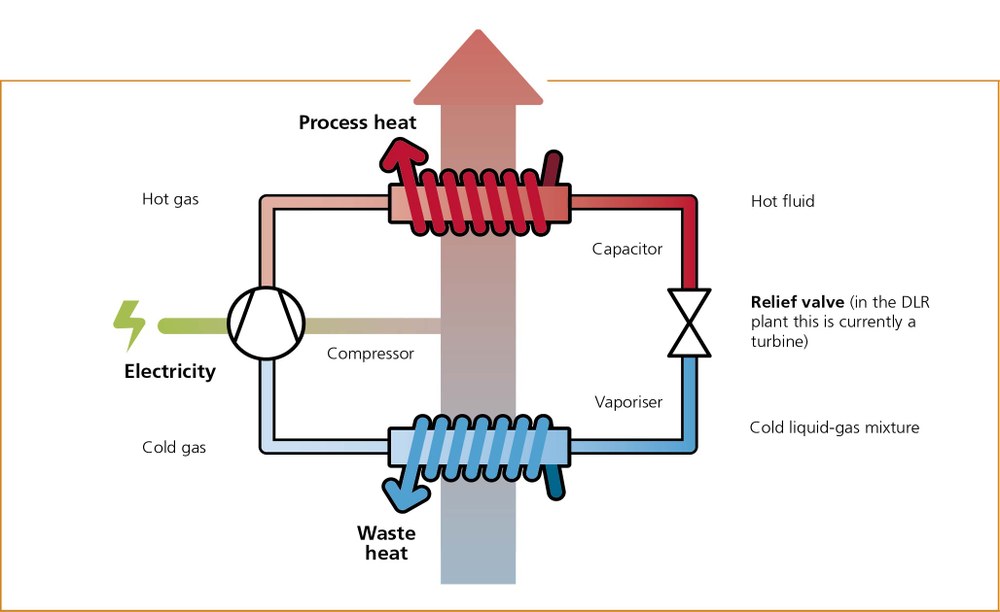

Heat pumps are used to cool or heat. These processes require energy in the form of electricity. "Heat pumps are becoming an increasingly interesting technological component for both private households and for industry. They provide a solution to electrifying the heating sector and thus avoiding emissions – provided that the electricity used comes from renewable energy sources," explains Panagiotis Stathopoulos of the DLR Institute of Low-Carbon Industrial Processes. "This is because heat pumps produce several times as much heat per unit of electricity consumed. This is significantly more efficient than electric heaters or burning green hydrogen. However, heat pumps are complex systems with high installation costs."

"This technology has the potential to save a quarter of all industrial carbon dioxide emissions."

Dr. Panagiotis Stathopoulos, DLR Institute of Low-Carbon Industrial Processes

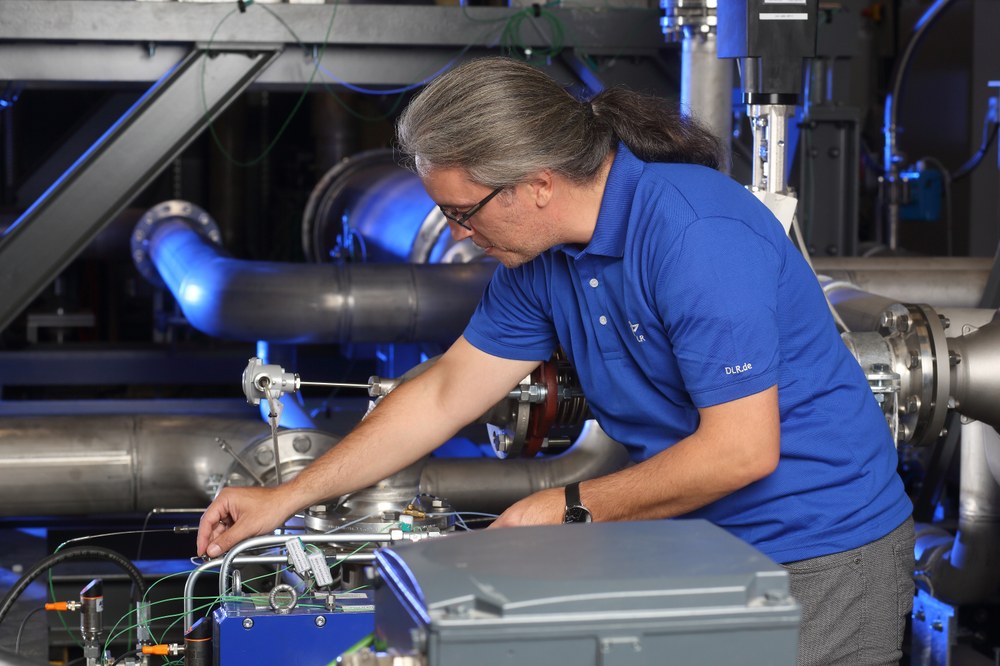

DLR's research work is primarily focussed on high-temperature heat pumps. These are intended to provide sustainable heat for industrial processes up to 300 degrees Celsius, for example for drying or steam generation. More than 80 percent of emissions from the industrial sector come from burning fossil fuels to generate process heat. "This technology has the potential to save a quarter of all industrial carbon dioxide emissions. Currently available heat pumps can provide heat up to a maximum of 150 degrees Celsius. With our development work we are closing the technological gap and, above all, developing the components and cycle processes required for this," says Stathopoulos. The scientists hope to use special heat pumps to boost the temperature of existing waste heat at the highest possible temperature.

To this end, one-of-a-kind pilot plants are being built at the DLR sites in Cottbus and Zittau. The 'CoBra' prototype was inaugurated in the summer of 2022 and works with dried air as a heat transfer medium. The name CoBra comes from Cottbus, the location of the plant, and the Brayton thermodynamic process, which describes the basic principle of the facility. Here, the researchers want to demonstrate the basic principle of heat pumps in the high-temperature range. New compression systems that can withstand relatively high temperatures and do not require expensive materials, as well as compact, efficient and inexpensive heat exchangers are the next development goals. The second pilot plant is scheduled to go into operation in Zittau next year. This plant works with the Rankine Cycle, in which water is the working fluid – unlike the Brayton Cycle, which works with air. The operating strategy – that is, the right temperature and pressure at the right time – is central in this process to increase heat very efficiently to a higher temperature level.

Heating with lime – the art (and science) of heat storage

The use of electricity from renewable energy sources for heating alongside the electrification of heat generation offers the opportunity to decarbonise the heating sector and thus massively reduce its carbon dioxide emissions. However, since the availability of renewable electricity is dependent on the weather and the season, energy systems of the future will also need heat storage.

At the DLR Institute of Engineering Thermodynamics, teams are developing innovative storage solutions based on different materials for a temperature range of 100 to 1000 degrees Celsius, with storage periods of up to several months. A wide variety of storage media are used, from liquids such as molten salt and thermal oil to compressed air and solids such as cement, ceramic particles and lime.

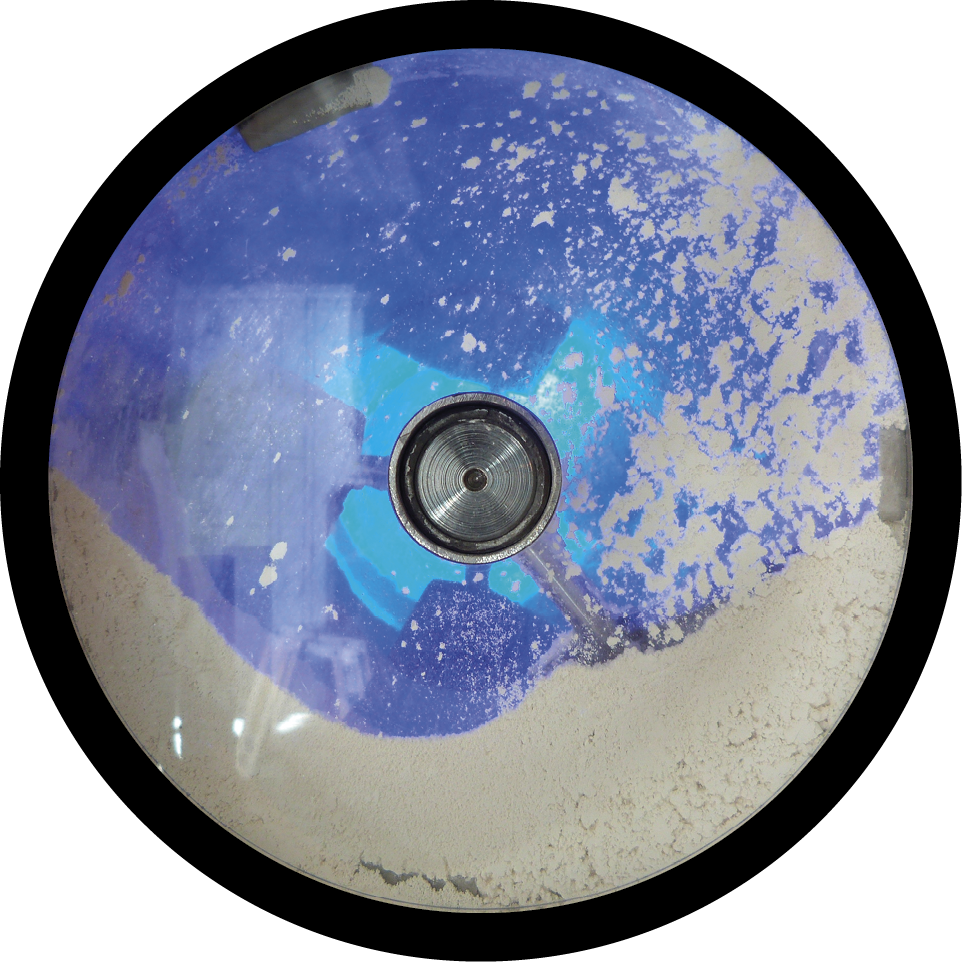

A team led by Marc Linder and Matthias Schmidt has been working successfully for several years on climate-neutral ways to heat buildings with a heat storage system using quicklime: The DLR researchers are currently testing a pilot facility together with the University of Stuttgart and are using this technology for the first time and on a larger scale outside of the laboratory.

René Müller Photographie, Stuttgart

Lime storage tanks use the chemical reaction of quicklime and water to generate heat. They first heat lime powder, called slaked lime, in a furnace to over 450 degrees Celsius using energy from renewable energy sources. The water bound in the lime escapes and quicklime is produced. This can be stored relatively easily and for months without loss. When heat is required, water is added to the quick lime. The two substances react and slaked lime is produced again alongside a temperature of over 100 degrees Celsius. "The heating output can be regulated by the quantities of lime and water introduced," explains Schmidt. "If the slaked lime is burned again, it can be reused to store energy. This process can be repeated as often as desired." With this principle, renewable energy can be stored in summer and used for heating in winter. With the operation of the pilot plant, the researchers want to gain important insights into how such a heating system can best be controlled and thus get closer to its practical application. Lime storage tanks would be particularly interesting for private households because lime is inexpensive and available in large quantities. Entire residential areas could also be supplied in this way – so perhaps in the near future a tanker will no longer bring oil for heating, but a container full of lime.

Interview: Do we have a heat problem?

Three questions for Christian Sattler, Divisional Board Member for Energy and Transport at DLR and Director of the DLR Institute of Future Fuels

Why has heat been out of the spotlight for so long? Do we have a heat problem?

: No, we don't have a heat problem, but we do have a demand for heat, both for heating buildings and for industrial processes. The problem lies in carbon dioxide emissions – heat is primarily generated by burning fossil fuels. Another aspect is security of supply.

How can research and technology help?

: For example, by developing efficient energy conversion processes and storage systems to provide renewable energy as heat whenever it is needed.

Could Germany or indeed Europe become self-sufficient in heat?

: It is possible, but that might not be the best solution. Unlike electricity or fuel, heat cannot be transported over any distance, and the use of renewable energy sources to generate heat requires a lot of space. Sector coupling is therefore a necessary principle, especially in conurbations, where residues and stored energy can be used in addition to electricity and waste heat. This could be sourced from other regions where more renewable energy is available per unit area, which can therefore be stored more efficiently.

An article by Denise Nüssle from the DLRmagazine 171