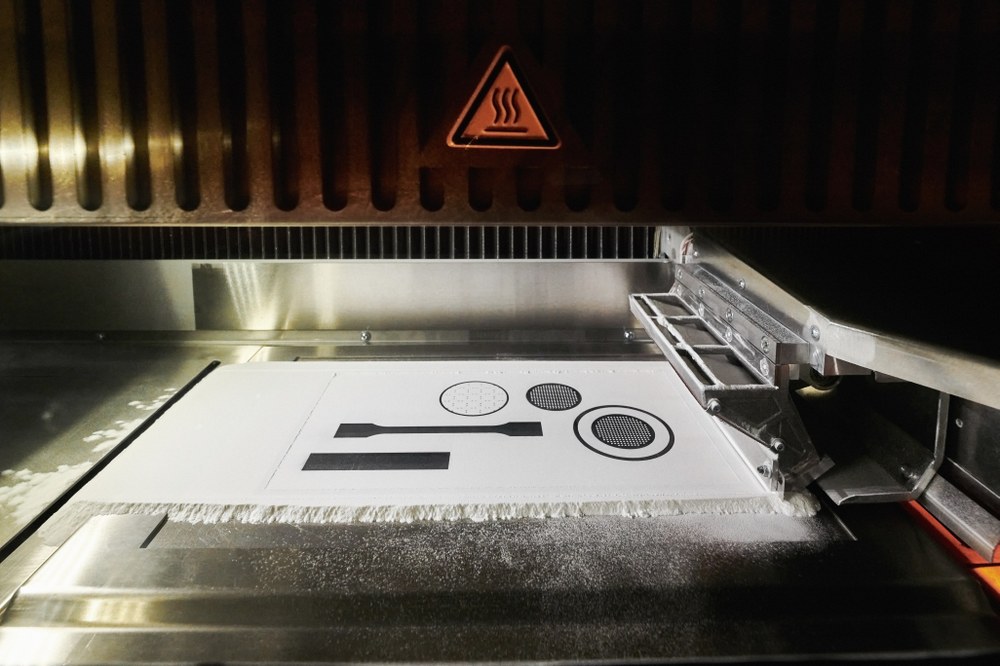

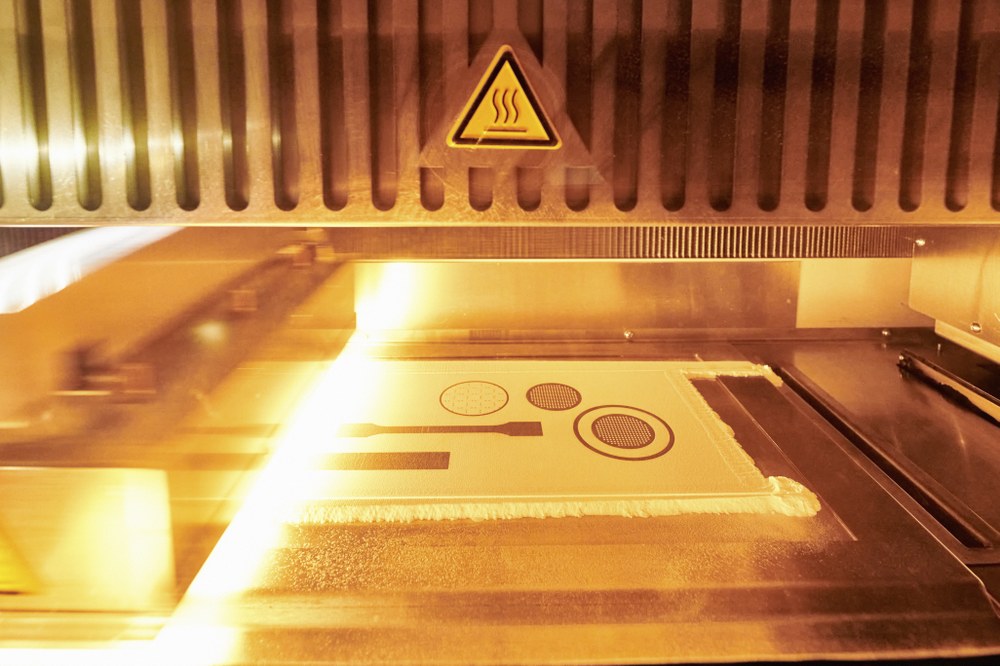

The technology of high-speed sintering (HSS) is based on the fact that black ink and thermal energy are introduced into white powder in order to generate components. It only processes thermoplastics, which are sintered using an infrared lamp.

First, a thin, rectangular layer of powder is applied to a build platform. A print head then applies black ink locally to the areas within this layer where a component is to be generated later. In the next step, an infrared lamp is used to apply heat to the entire powder layer, causing the black areas to absorb it more strongly than the white areas. As a result, the powder only exceeds the melting temperature in the desired black areas and melts there. The building platform now lowers by the corresponding layer height and a new thin layer of powder is applied. This process is repeated layer by layer until the desired component has been generated. In this project, the Voxeljet VX200 HSS system is used, which has an installation space of 290 x 140 x 180 mm. Larger components can be divided into segments and then joined. The process principle can also be easily scaled up to larger systems.

The overarching goal is the efficient and sustainable use of additive manufacturing processes in the automotive industry, in the commercial vehicle sector or in neighbouring industries with similar challenges. In terms of this process, this can only be achieved through research along the entire process chain, from the initial idea through to the reuse of used powder. Thanks to the open machine concept, we can influence a large number of process parameters and thus, for example, independently qualify new materials or optimise existing materials. As no support structure is required for this process, complex components with a very high potential for lightweight construction can be realised with the same layer time. This makes it easy to generate optimised components for various applications in industrial use. One example of this is current research into components with an internal grid structure, which are then filled with aerogel. Such a composite material can be particularly suitable for heat and sound insulation in vehicles. In order to maximise the sustainability of the process and increase economic efficiency at the same time, the ageing of the powder is also being investigated in addition to structural optimisation in order to be able to add as much recycled powder as possible to a new process.

Kontakt

Dr.-Ing. Gerhard Kopp