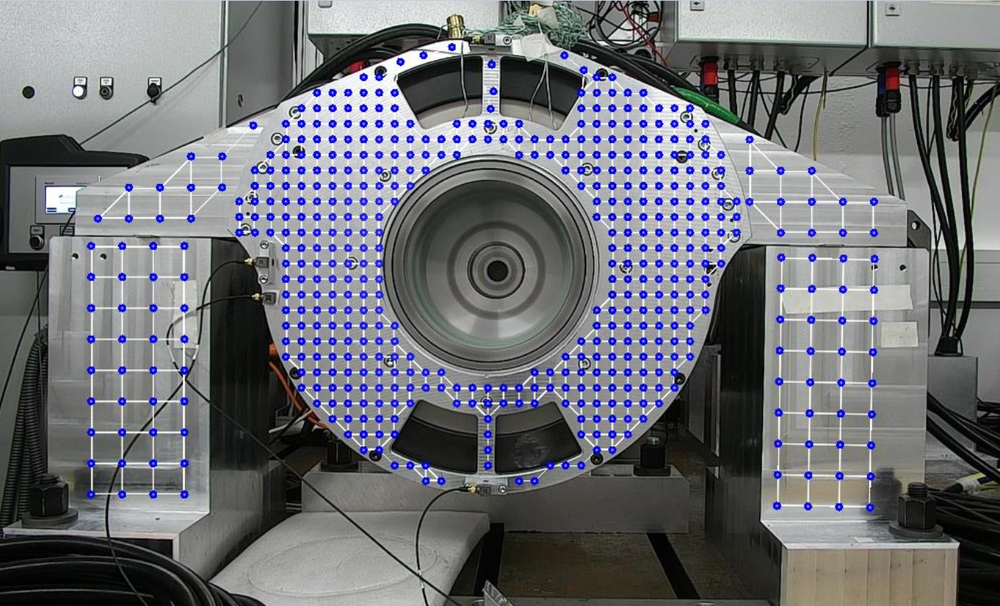

Electric motor test bench (Ilmenau)

Fields of application | |

|---|---|

Power and efficiency measurement of electrical machines | |

Thermal measurement | |

Technical data | |

Maximum drive power | 400 kW |

Maximum speed | 8,000 rpm |

Maximum torque | 3,000 Nm |

Shaft connection | Taper bush |

Available components | |

Inverter | CAN, RS422 |

Input voltage | 0-850 V |

Power | 160 kW / 320 kW |

Output voltage | 560 V AC |

Output current | 270 A Eff |

Rotary encoder | Endat compatible |

DC-Source | |

Power | 120 kW |

Current | 720 A |

Voltage | 0 – 1000 V |

Cooling water temperature control | 90 kW cooling capacity / 6 kW heating capacity |

Flow rate | up to 60 l/min |

Pressure | up to 3.8 bar |

Temperature range | 20-90 degrees |

Auxiliary voltage | 5, 12, 24, 48 and 72 V |

Measurement technology | HBM GEN7ta (CAN-Recording, 6 Phases) |

Sampling rate | 2 MS/s |

Software | Perception |

Sensors | LEM-Transducer IN500 (500Aac rms) |

Torque | Kistler 3kNm and Kistler 100N |

Temperature | Type K thermocouples |

Fields of application | |

|---|---|

Vibration measurement | |

Harmonics of mechanical excitation | |

Harmonics of electromagnetic excitation | |

Evaluation of mechanical noise sources | |

Modal analysis | |

Polytec PSV Qtec Scanning Vibrometer | |

Frequency range | up to 20 kHz |

Resolution | 24 bit |

Speed measuring range | 25mm/s to 12,5 m/s |

Scan angle H x V | 50° x 40° |

Shortest measuring distance | 125 mm |

Accessories | Modal hammer, reference sensor |

Accelerometer HBK 4528-B-001 | |

Quantity | 4 units (can be used simultaneously) |

Frequency range X, Y | 0,3 Hz to 10 kHz |

Frequency range Z | 0,3 Hz to 12,8 kHz |

max. acceleration | 700 m/s² (71g) |

Operating temperature | -60 to +165 °C |

Evaluation software | |

BK Connect |