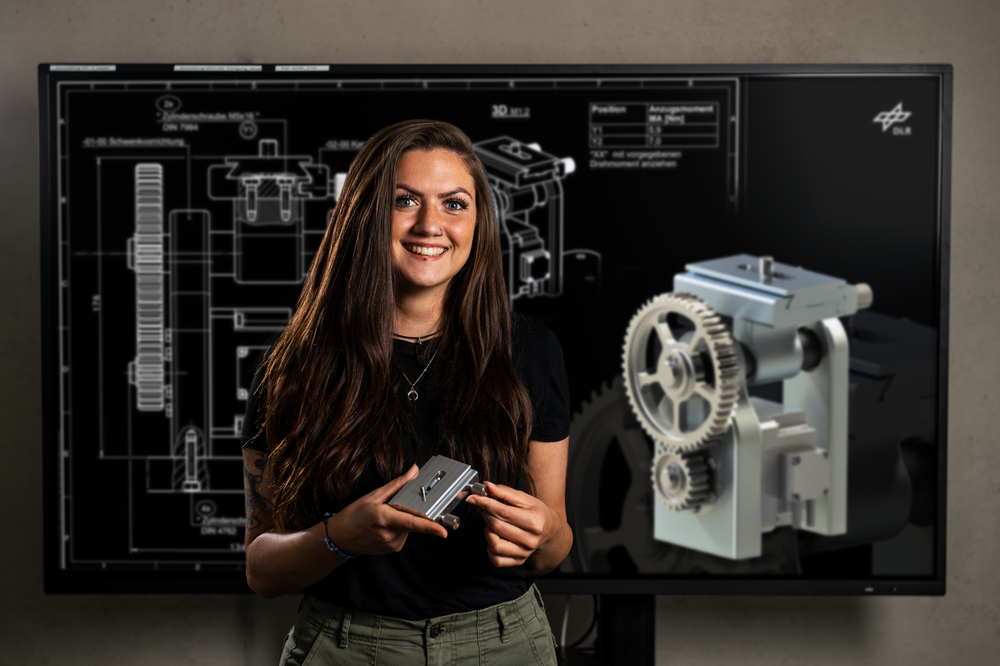

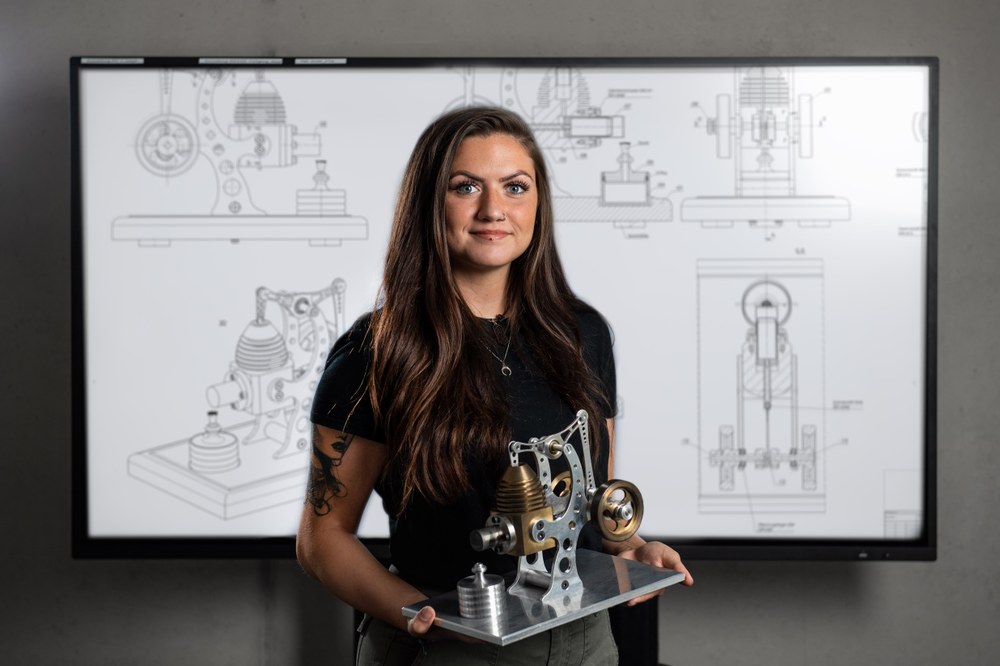

Carina Bach

Apprenticeship: Technical product design – machine and system design

Carina Bach joined DLR at the site in Cologne as a trainee in 2019 after finishing her vocational training. She completed a three-year apprenticeship as a technical product designer at Systemhaus Technik West. In this interview, she talks about the first few months at DLR, the most rewarding moment of her training and her day-to-day work.

Carina, what do you like most about your apprenticeship at DLR?

Carina: The first thing that comes to mind is the independent learning. Particularly in STEM subjects, the best way to consolidate what you have learnt is to come up with your own solutions. And this is precisely the type of learning that is used here in the training programme. You receive support according to your individual needs – whether through the small trainee groups of two people per apprenticeship year or through the personal support provided by the trainer. At the same time, everyone is given the opportunity to independently explore the content of the technical product designer apprenticeship in a self-determined way – a combination that has certainly already had a positive impact on one or two of my grades.

It's also worth mentioning that I live very centrally in Cologne. My commute to work is mainly through wooded areas in the immediate vicinity of the site, which has already made the unreliable public transport more pleasant for me.

What can you learn here?

„Everyone learns two CAD programmes, which offers great flexibility further down the line“

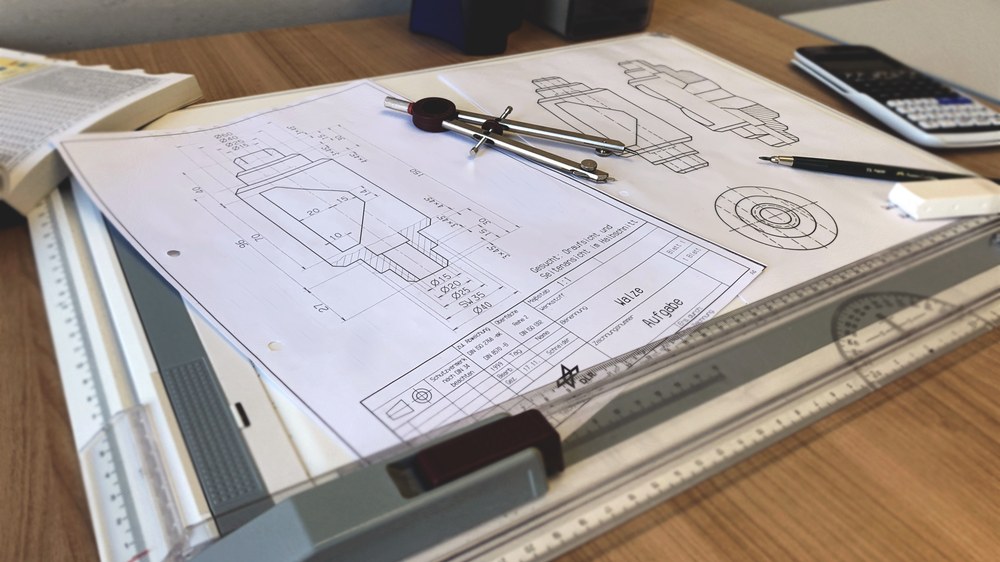

Carina: To begin with, you will gain a basic understanding of the various materials and manufacturing processes in the training workshop before moving on to drawing at the drawing board.

You will learn the former working methods of a drafter in order to lay the foundations of geometric understanding for the subsequent work of creating CAD drawings or 3D models – because even CAD programmes are not without their errors. Here at DLR, we work with CATIA V5, while SolidWorks is used in the vocational training modules and in the Part I final examination. This means that everyone is taught to use two CAD programmes, which offers great flexibility further down the line, regardless of whether they end up working at DLR or in other fields.

Personal skills, such as the ability to work in a team and take a stand when exchanging ideas on current projects, are also strengthened in plenary sessions with colleagues.

What does your typical working day involve?

Carina: The working day starts between 6:30 and 9:00 – flexible working hours. This is a great way to start the office day with plenty of energy and concentration, regardless of what happened the previous day. While all trainees worked together in one large office at the start of my training, each trainee was assigned an office of their own in the long term during the pandemic. I wasn't initially thrilled about this, but it was actually an advantage during the intensive exam phase, especially as my fellow trainees were right next door when I had questions.

Things are different in the vocational training modules: Vocational school is held twice per apprenticeship year, with 6 to 8 weeks of lessons. We, the technical product designers, are based at the campus in Cologne-Deutz, as are the industrial mechanics from the training workshop.

How were your first few months at DLR?

Carina: Exciting. I was finally part of this organisation. And yes, I was certainly a little bit proud to have been chosen over the other candidates in the application process a year earlier.

„Exciting. I was finally part of this organisation. “

Everything was new: drawing on the drawing board, the first 1.5 months in the training workshop, where I was able to learn manual skills together with the industrial mechanic trainees in an environment that was largely unknown to me, but above all getting up in the morning feeling that I had the opportunity to work in a position that I had actively chosen and which would allow me to grow over the next 3.5 years.

What was your favourite experience during your apprenticeship?

Carina: One of the best things was the first time I was asked for advice by my trainer and received the feedback that I was now more of an employee than an apprentice.

What special skills can you make good use of in your job?

Carina: My analytical thinking. A large part of the job consists of activities that need to be structured. As in, what is the most sensible way to proceed and what is the first thing to tackle – whether it's analysing complex problems during the prototyping process or existing schematics, but also structuring my own approach when working with the engineers in the Design department.

Leave us a final thought.

Carina: A little update on me... After I was able to shorten the apprenticeship to a total of three years, I successfully passed the final exam in June 2022. I'm no longer working as an apprentice, but as a permanent employee in the Design department at Systemhaus Technik. In September 2022, I started a part-time degree in mechanical engineering so that I might be able to work here as an engineer in the near future.